Polygon structure composite acoustic board based on negative mass

A polygonal structure and negative mass technology, applied in the field of vibration reduction and noise reduction, can solve the problems of large structure size, narrow sound absorption frequency band, complex process, etc., and achieve high shear modulus, low surface density, and good low-frequency sound absorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

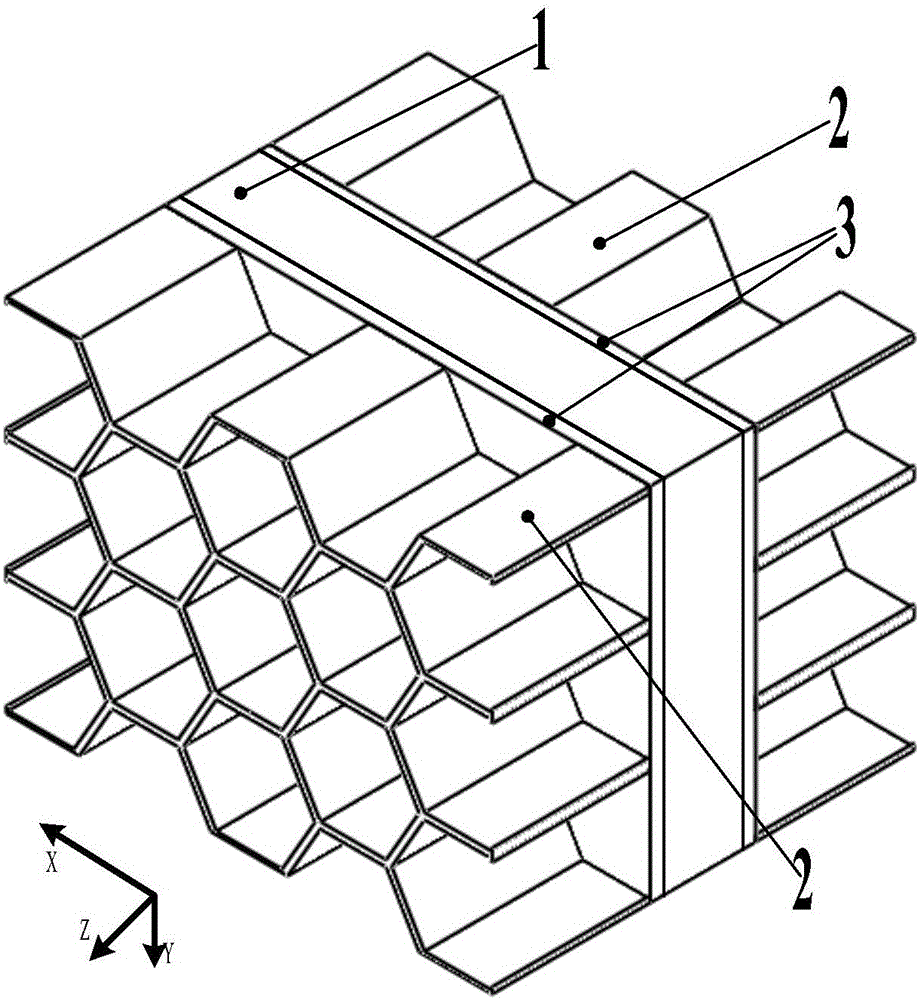

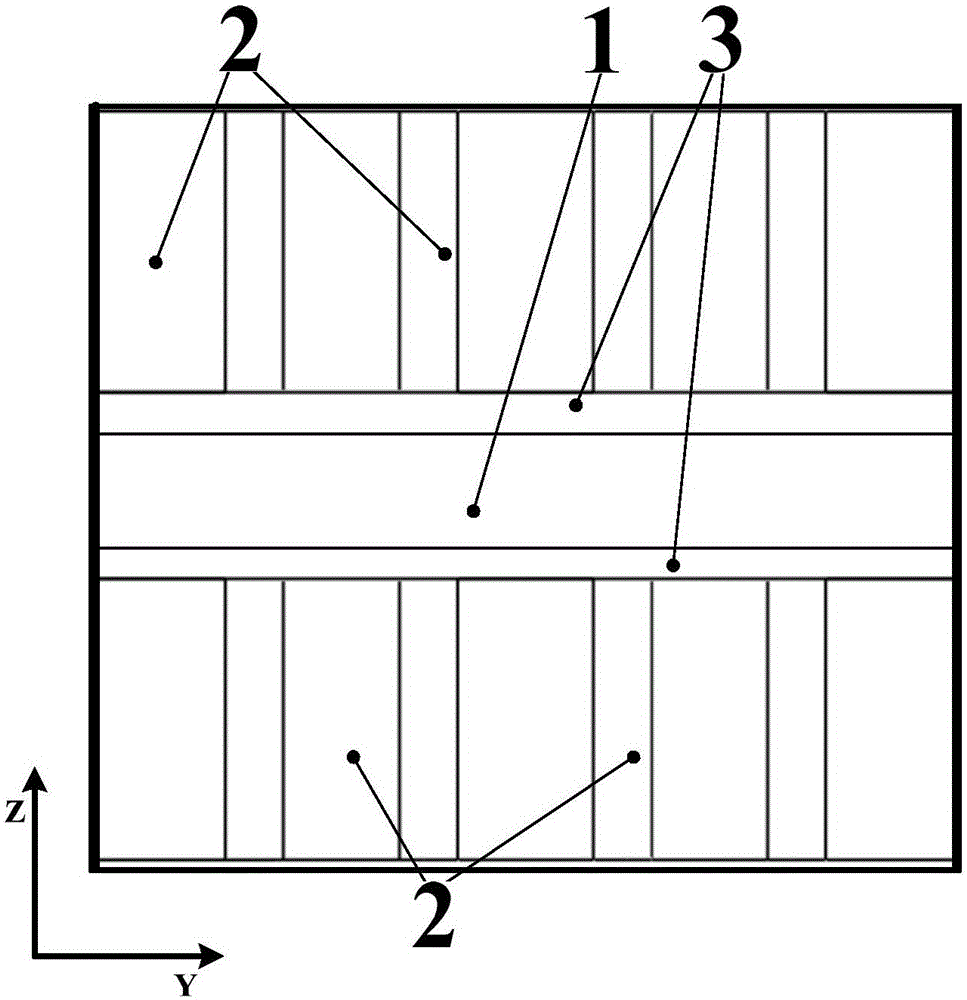

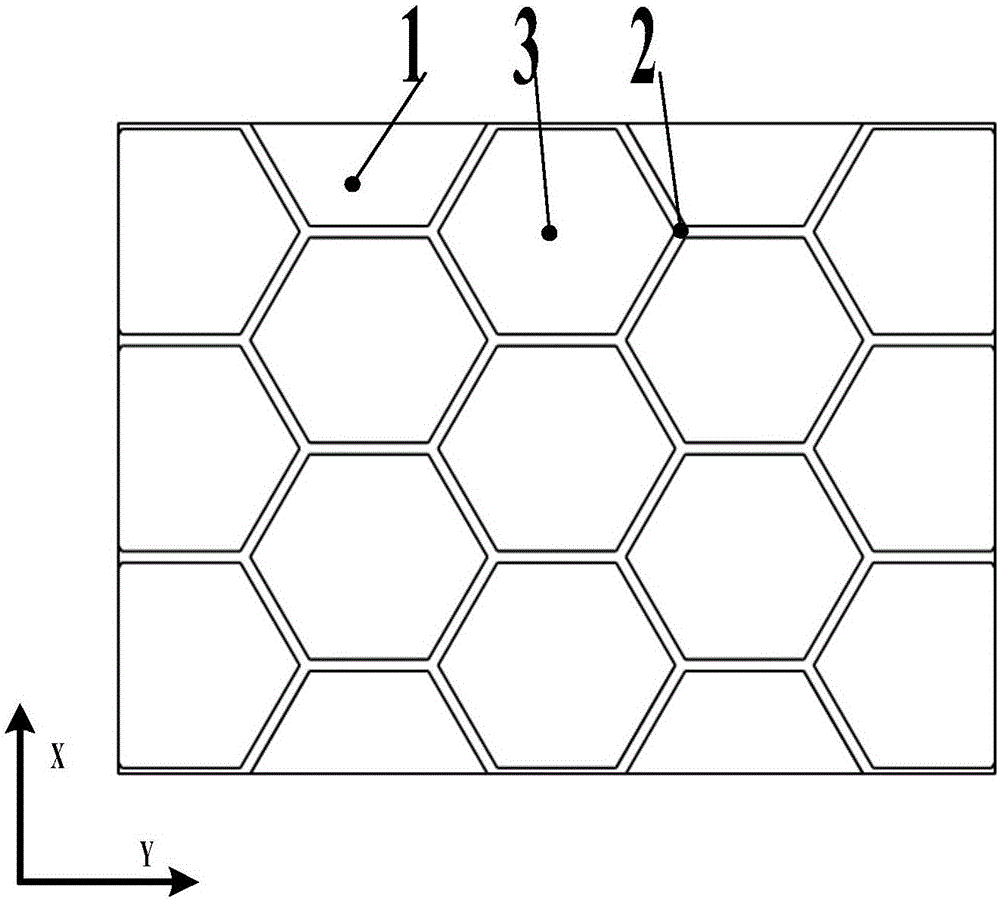

[0018] refer to figure 1 , figure 2 and image 3 , a composite sound-absorbing panel with a polygonal structure based on negative mass, including a polygonal structure layer 2 with a negative mass effect along the Z direction, and the polygonal structure layer 2 is bonded to both sides of the middle layer 1 through an adhesive layer 3 to form a whole , the material of the intermediate layer 1 is ethylene-vinyl acetate copolymer, and the thickness of the intermediate layer 1 is as small as possible under the requirements of mechanical properties and acoustic properties, so as to reduce the surface density of the overall structure and reduce the weight; The material of the bonding layer 3 is a two-component epoxy resin glue, bonding requirements: clean the middle layer 1 and the polygonal structure layer 2 at room temperature (25°C), and then apply the bonding mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com