Preparation of sisal fiber porous material capable of improving high, medium and low frequency sound absorption performance

A technology of sisal fiber and porous material, which is applied in fiber raw material treatment, cellulose pulp post-treatment, pulp property modification, etc., can solve problems such as high cost, complicated process, and high specific weight, and achieve increased fiber surface area and sound absorption The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

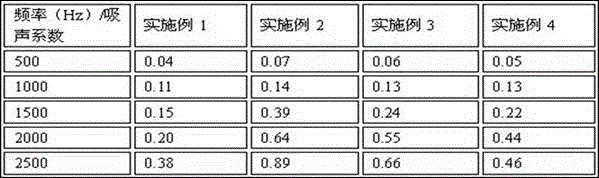

Embodiment 1

[0021] Heat the sisal fiber material with a diameter of 100um and a length of 2mm in 20wt% sodium hydroxide solution and soak it at 70°C for 6h, then dry it in a drying oven at 50°C, and mix the treated sisal fiber with 15wt% polyurethane adhesive solution Put them into the reaction tank, use mechanical high-speed stirring to make the fiber solution into a suspension, then cast and mold, and finally ripen to obtain a sisal fiber sample with a thickness of 6mm. According to the national standard GB-T 18696.2-2002 "Measurement of Sound Absorption Coefficient and Acoustic Impedance in Acoustic Impedance Tube Part 2. Transfer Function Method", the obtained sisal fiber samples were measured through the acoustic impedance tube for normal sound absorption coefficient ( The following examples are also measured using this method).

Embodiment 2

[0023] Heat the sisal fiber material with a diameter of 150um and a length of 3mm in a mixed solution of 15wt% sodium hydroxide solution and 5wt% hydrogen peroxide to soak at 75°C for 7h, and then dry it in a drying oven at 60°C. The treated sisal fiber, 20 The %wt polyurethane adhesive solution was added into the reaction tank, and the fiber solution was suspended by mechanical high-speed stirring, and then poured into a mold, and finally matured to obtain a sisal fiber sample with a thickness of 8mm. According to the national standard GB-T 18696.2-2002 "Measurement of Sound Absorption Coefficient and Acoustic Impedance in Acoustic Impedance Tube Part 2. Transfer Function Method", the obtained sisal fiber samples were measured through the acoustic impedance tube for normal sound absorption coefficient ( The following examples are also measured using this method).

Embodiment 3

[0025] Heat the sisal fiber material with a diameter of 175um and a length of 4mm in a mixed solution of 10wt% sodium hydroxide solution and 10wt% hydrogen peroxide to soak at 80°C for 8h, and then dry it in a drying oven at 65°C. The treated sisal fiber, 25 The %wt polyurethane adhesive solution was added into the reaction tank, and the fiber solution was suspended by mechanical high-speed stirring, and then poured into a mold, and finally matured to obtain a sisal fiber sample with a thickness of 10mm. According to the national standard GB-T18696.2-2002 "Measurement of Sound Absorption Coefficient and Acoustic Impedance in Acoustic Impedance Tube Part 2. Transfer Function Method", the obtained sisal fiber samples were measured through the acoustic impedance tube for normal sound absorption coefficient (The following examples are also measured using this method).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com