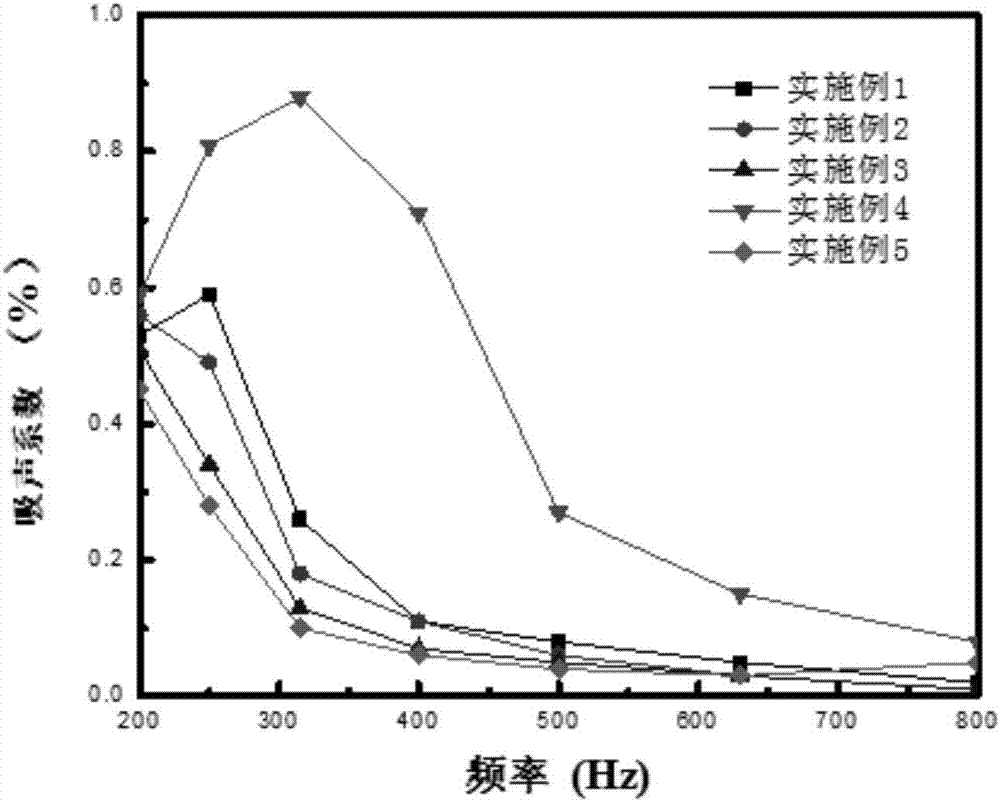

Layered structural composite material for low-frequency sound absorption and preparation method of layered structural composite material

A layered structure and composite material technology, applied in the field of material processing, can solve the problems of bulky composite materials and achieve excellent low-frequency sound absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method for preparing a layered structure composite material for low-frequency sound absorption, the preparation steps are as follows:

[0019] (1) Modification of barium titanate powder: take a certain amount of barium titanate powder and 2.5% TMC-101 of the powder mass, put it into a ball mill and mill it for 5 minutes to obtain the modified barium titanate;

[0020] (2) Preparation of piezoelectric composite materials: Add 100 parts of nitrile rubber, 3 parts of ZnO, 0.75 parts of stearic acid, 0.75 parts of zinc stearate, 0.75 parts of magnesium oxide, and antioxidant 0.6 parts of 4010, 0.6 parts of accelerator TMTD, 0.6 parts of accelerator CZ and 1 part of sulfur, the volume ratio of conductive carbon black is 6%, the volume ratio of barium titanate powder is 8%, knead at 40 ° C for 25 minutes The mixed rubber was obtained, and the mixed rubber was vulcanized for 15 minutes under the conditions of 165 ° C and 15 MPa to obtain a piezoelectric composite material; ...

Embodiment 2

[0024] A method for preparing a layered structure composite material for low-frequency sound absorption, the preparation steps are as follows:

[0025] (1) Modification of barium titanate powder: Take a certain amount of barium titanate powder and 3% isopropyl tris(dioctyl phosphate acyloxy) titanate (TMC-102) of the powder mass, put Ball milling in a ball mill for 9 minutes to obtain modified barium titanate;

[0026] (2) Preparation of piezoelectric composite materials: Add 100 parts of nitrile rubber, 4 parts of ZnO, 1.2 parts of stearic acid, 1.2 parts of zinc stearate, 1.2 parts of magnesium oxide, and antioxidant 0.8 parts of 4010, 1.6 parts of accelerator TMTD, 0.8 parts of accelerator CZ and 0.9phr of sulfur, the volume ratio of conductive carbon black is 7%, the volume ratio of barium titanate powder is 10%, mixed at 60°C for 25min The mixed rubber is obtained, and the mixed rubber is vulcanized at 170°C and 15MPa for 20 minutes to obtain a piezoelectric composite ma...

Embodiment 3

[0030] A method for preparing a layered structure composite material for low-frequency sound absorption, the preparation steps are as follows:

[0031] (1) Modification of barium titanate powder: take a certain amount of barium titanate powder and 4% bis(dioctyloxypyrophosphate) ethylene titanate (TMC-201) of the powder mass, put Ball milling in a ball mill for 10 minutes;

[0032] (2) Preparation of piezoelectric composite materials: add 100 parts of nitrile rubber, 5 parts of ZnO, 1.5 parts of stearic acid, 1.5 parts of zinc stearate, 1 part of magnesium oxide, and anti-aging agent in the internal mixer or open mill 1 part of 4010, 2 parts of accelerator TMTD, 1 part of accelerator CZ and 1.5 parts of sulfur, the volume ratio of conductive carbon black is 8%, the volume ratio of barium titanate powder is 18%, mixed at 60 ° C for 28 minutes The mixed rubber is obtained, and the mixed rubber is vulcanized at 170°C and 15MPa for 20 minutes to obtain a piezoelectric composite m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sound absorption coefficient | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com