A barium titanate/rubber piezoelectric composite material for low-frequency sound absorption and its preparation method

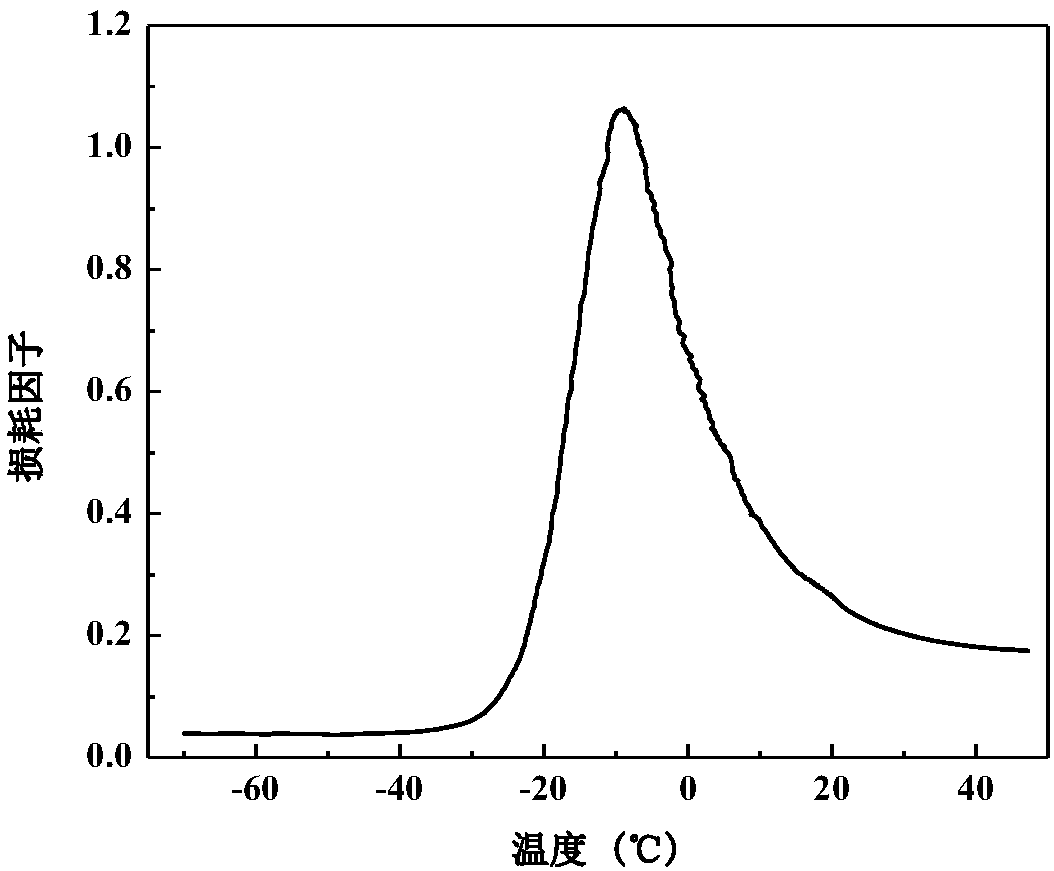

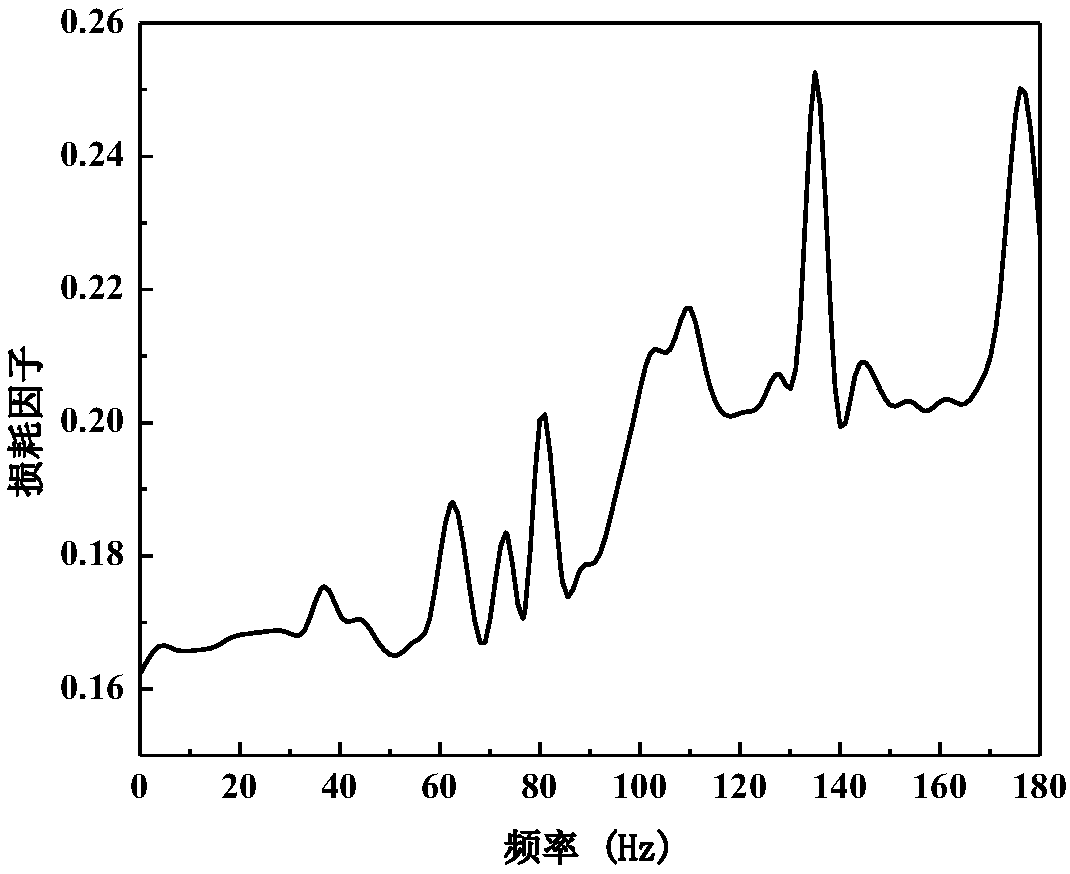

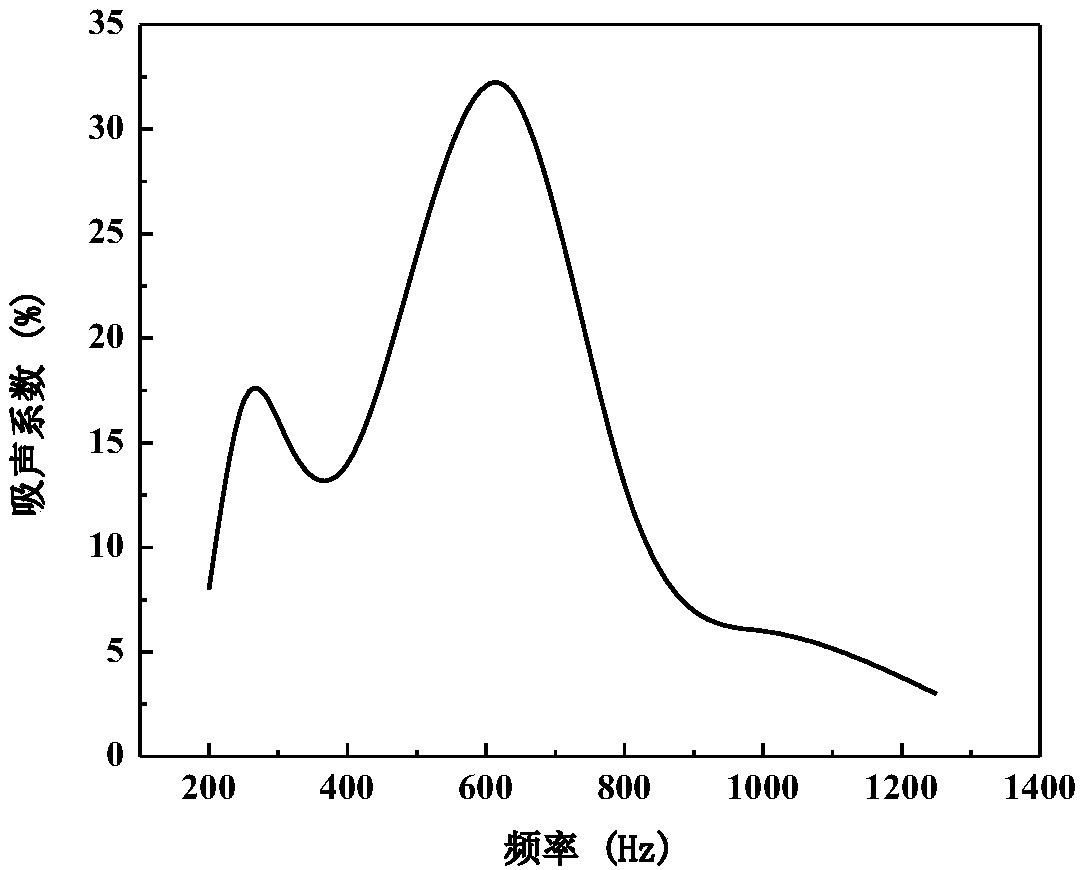

A piezoelectric composite material, barium titanate technology, applied in the direction of material selection for piezoelectric devices or electrostrictive devices, manufacturing/assembly of piezoelectric/electrostrictive devices, device material selection, etc., can solve the problem of low frequency. Problems such as poor sound absorption, low intensity, and narrow sound absorption frequency range achieve the effect of wide damping temperature range and high storage modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A barium titanate / rubber piezoelectric composite material for low-frequency sound absorption, prepared by the following method:

[0024] (1) Pretreatment of barium titanate ceramic powder: put the barium titanate ceramic powder into a ball mill for ball milling for 5 minutes; use a silane coupling agent as a modifier, and the dosage is 2% of the mass of the barium titanate ceramic powder; The ball-milled barium titanate ceramic powder and modifying reagent were placed in a high-speed mixer, and stirred at a high speed of 1200r / min for 20min to obtain the pretreated barium titanate ceramic powder, which was dried for later use;

[0025] (2) Weigh the rubber matrix raw material according to the following formula: 100 parts by weight of nitrile rubber, 4 parts by weight of ZnO, 1 part by weight of zinc stearate, 1 part by weight of stearic acid, 0.8 parts by weight of antioxidant 4010, and 1 part by weight of sulfur , accelerator DM 0.8 weight portion, accelerator CZ 0.8 w...

Embodiment 2

[0029] A barium titanate / rubber piezoelectric composite material for low-frequency sound absorption, prepared by the following method:

[0030] (1) Barium titanate ceramic powder pretreatment: put the barium titanate ceramic powder into a ball mill for ball milling for 8 minutes; use a silane coupling agent as a modifier, and the dosage is 3% of the mass of the barium titanate ceramic powder; The ball-milled barium titanate ceramic powder and modifying reagent were placed in a high-speed mixer, and stirred at a high speed of 1300r / min for 25min to obtain the pretreated barium titanate ceramic powder, which was dried for later use;

[0031] (2) Weigh the rubber matrix raw material according to the following formula: 100 parts by weight of nitrile rubber, 4 parts by weight of ZnO, 1 part by weight of zinc stearate, 1 part by weight of stearic acid, 0.8 parts by weight of antioxidant 4010, and 1 part by weight of sulfur , accelerator DM 0.8 weight portion, accelerator CZ 0.8 weig...

Embodiment 3

[0035] A barium titanate / rubber piezoelectric composite material for low-frequency sound absorption, prepared by the following method:

[0036] (1) Pretreatment of barium titanate ceramic powder: put the barium titanate ceramic powder into a ball mill for ball milling for 10 minutes; use a silane coupling agent as a modifier, and the dosage is 5% of the mass of the barium titanate ceramic powder; The ball-milled barium titanate ceramic powder and modifying reagent were placed in a high-speed mixer, and stirred at a high speed of 1400r / min for 20min to obtain the pretreated barium titanate ceramic powder, which was dried for later use;

[0037] (2) Weigh the rubber matrix raw material according to the following formula: 100 parts by weight of nitrile rubber, 4 parts by weight of ZnO, 1 part by weight of zinc stearate, 1 part by weight of stearic acid, 0.8 parts by weight of antioxidant 4010, and 1 part by weight of sulfur , accelerator DM 0.8 weight part, accelerator CZ 0.8 wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com