DOPO derivative modified organosilicon damping additive and preparation method and application thereof

A kind of polymer, selected technology, applied in the field of silicone damping materials, can solve the problems of small molecular weight and easy precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

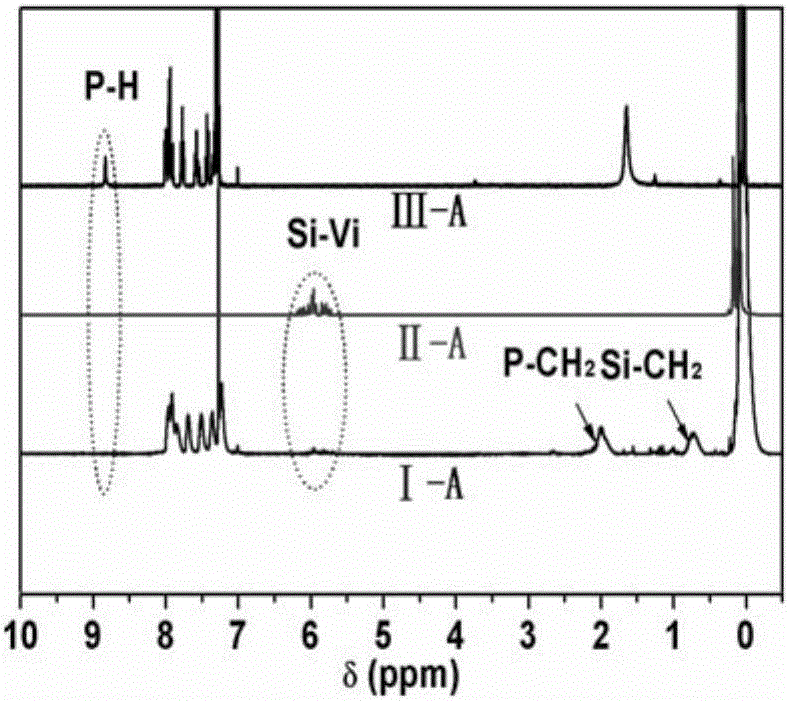

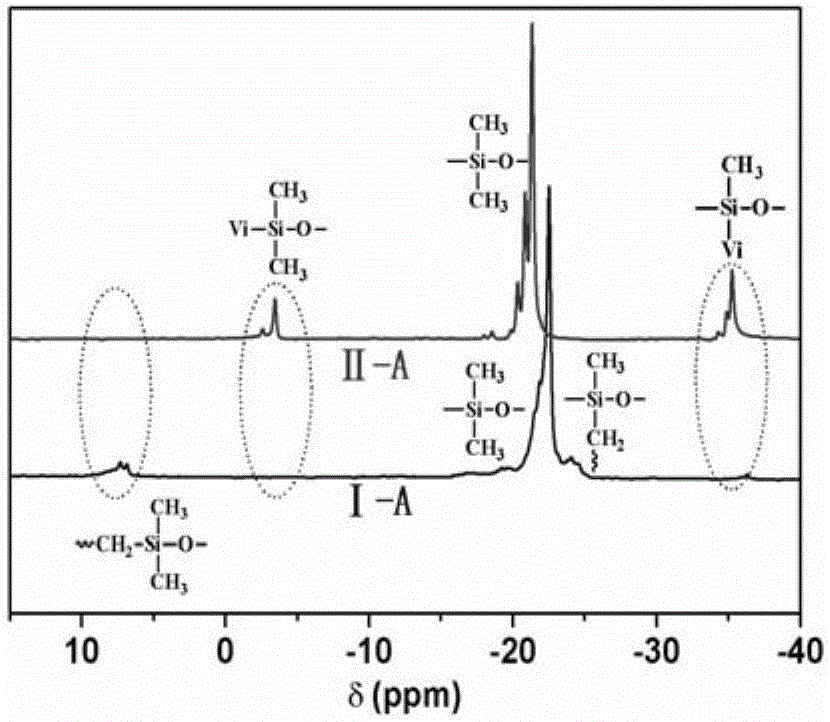

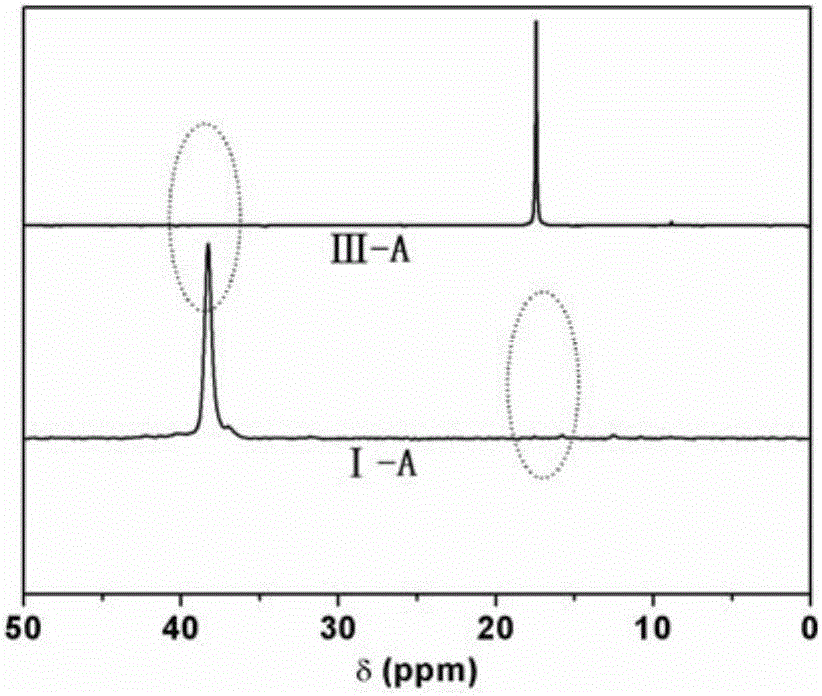

[0065] Example 1. Preparation of DOPO derivative modified polysiloxane damping agent and damping silicone rubber

[0066] 1. Preparation of DOPO derivative modified polysiloxane damping agent

[0067] (1) Preparation of α, ω-vinyl poly(dimethyl-methylvinyl)siloxane (formula II-A): 100g octamethylcyclotetrasiloxane, 8.5g tetramethyltetraethylene Cyclotetrasiloxane, 6.1g of tetramethyldivinyldisiloxane and 0.1g of tetramethylammonium hydroxide were added into a 250mL three-necked flask, and the temperature was raised to 90°C for an equilibrium reaction for 4h under a nitrogen atmosphere. After the reaction was completed, the temperature was increased to 150°C and maintained for 1 hour to decompose and destroy the catalyst. Finally, the temperature was lowered to 120°C, and low-molecular substances were removed in vacuum until there was no distillate. Lower the temperature, stop the decompression, and discharge after cooling to obtain α,ω-vinyl poly(dimethyl-methylvinyl)siloxan...

Embodiment 2

[0079] Example 2, preparation of DOPO derivative modified polysiloxane damping agent and damping silicone rubber

[0080] 1. Preparation of DOPO derivative modified polysiloxane damping agent

[0081] (1) Preparation of α, ω-vinyl poly(dimethyl-diphenyl-methylvinyl)siloxane (formula II-B): 100g octamethylcyclotetrasiloxane, 26.2g octamethylcyclotetrasiloxane, Phenylcyclotetrasiloxane, 23.2g tetramethyltetravinylcyclotetrasiloxane, 12.6g tetramethyldivinyldisiloxane and 0.1g tetramethylammonium hydroxide were added to a 250mL three-necked flask, Under a nitrogen atmosphere, the temperature was raised to 90° C. for an equilibrium reaction for 4 h. After the reaction was completed, the temperature was increased to 150°C and maintained for 1 hour to decompose and destroy the catalyst. Finally, the temperature was lowered to 120°C, and low-molecular substances were removed in vacuum until there was no distillate. Lower the temperature, stop the depressurization, and discharge af...

Embodiment 3

[0092] Example 3, preparation of DOPO derivative modified polysiloxane damping agent and damping silicone rubber

[0093] 1. Preparation of DOPO derivative modified polysiloxane damping agent

[0094] (1) Preparation of α, ω-vinyl poly(dimethyl-methylphenyl-methylvinyl)siloxane (formula II-C): 100g octamethylcyclotetrasiloxane, 18.1g Methylphenyl cyclosiloxane, 28.9 tetramethyltetravinyl cyclotetrasiloxane, 12.6 g tetramethyl divinyl disiloxane and 0.1 g tetramethylammonium hydroxide were added to a 250 mL three-necked flask, Under a nitrogen atmosphere, the temperature was raised to 90° C. for an equilibrium reaction for 4 h. After the reaction was completed, the temperature was increased to 150°C and maintained for 1 hour to decompose and destroy the catalyst. Finally, the temperature was lowered to 120°C, and low-molecular substances were removed in vacuum until there was no distillate. Lower the temperature, stop the depressurization, and discharge the material after co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com