Flame-retardant vibration reduction and sound insulation material and preparation method thereof

A sound insulation material and a mixing technology, which are applied in the field of sound insulation materials and their preparation, can solve problems such as flammable materials and hidden dangers, and achieve the effects of improving physical properties, improving flame retardancy, and improving aging properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] An embodiment of the flame-retardant, vibration-damping and sound-insulating material of the present invention, the sound-insulating material in this embodiment contains the following components by weight:

[0039]

[0040]

[0041] The preparation method of the flame-retardant, vibration-damping and sound-insulating material described in this embodiment comprises the following steps:

[0042] (1) Put butyl rubber and EPDM rubber into an internal mixer to heat, stir and shear, and masticate at 80°C for 10 minutes;

[0043] (2) On the premise that the above two rubbers are blended uniformly, add stearic acid, white carbon black, carbon black, and 1 / 3 paraffin oil, stir evenly, and knead at 85° C. for 10 minutes;

[0044] (3) Add glass microspheres, 1 / 2 of light calcium carbonate, 1 / 2 of aluminum hydroxide, and 1 / 3 of paraffin oil, stir evenly, and knead at 85° C. for 10 minutes;

[0045] (4) Add expanded graphite and zinc borate, stir evenly, and knead for 10 minu...

Embodiment 2

[0049] An embodiment of the flame-retardant, vibration-damping and sound-insulating material of the present invention, the sound-insulating material in this embodiment contains the following components by weight:

[0050]

[0051]

[0052] The preparation method of the flame-retardant, vibration-damping and sound-insulating material described in this embodiment comprises the following steps:

[0053](1) Put butyl rubber and EPDM rubber into an internal mixer to heat, stir and shear, and masticate at 85°C for 10 minutes;

[0054] (2) On the premise that the above two rubbers are blended uniformly, add stearic acid, white carbon black, carbon black, and 1 / 3 paraffin oil, stir evenly, and knead at 90° C. for 15 minutes;

[0055] (3) Add glass microspheres, 1 / 2 of light calcium carbonate, 1 / 2 of aluminum hydroxide, and 1 / 3 of paraffin oil, stir evenly, and knead at 90°C for 15 minutes;

[0056] (4) Add expanded graphite and zinc borate, stir evenly, and knead for 15 minutes...

Embodiment 3

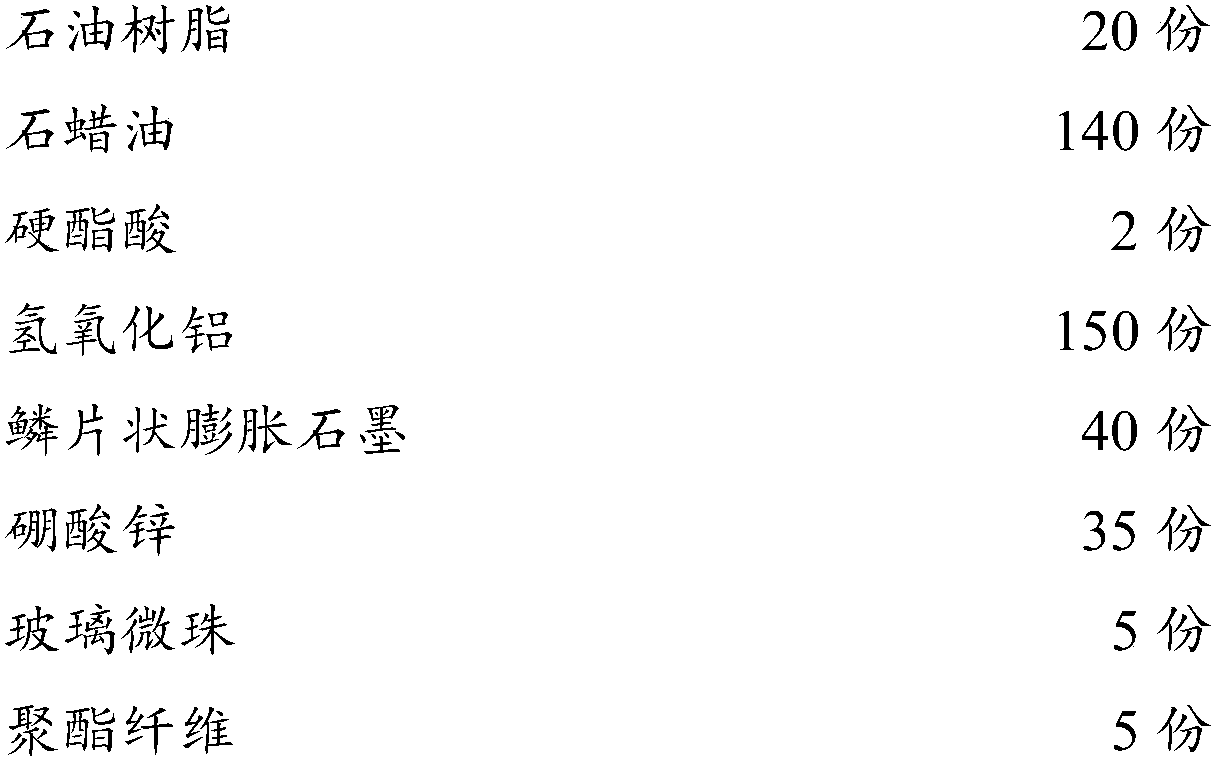

[0060] An embodiment of the flame-retardant, vibration-damping and sound-insulating material of the present invention, the sound-insulating material in this embodiment contains the following components by weight:

[0061]

[0062]

[0063] The preparation method of the flame-retardant, vibration-damping and sound-insulating material described in this embodiment comprises the following steps:

[0064] (1) Put butyl rubber and EPDM rubber into an internal mixer to heat, stir and shear, and masticate at 90°C for 10 minutes;

[0065] (2) On the premise that the above two rubbers are blended evenly, add stearic acid, white carbon black, carbon black, and 1 / 3 paraffin oil, stir evenly, and knead at 95° C. for 20 minutes;

[0066] (3) Add glass microspheres, 1 / 2 of light calcium carbonate, 1 / 2 of aluminum hydroxide, and 1 / 3 of paraffin oil, stir evenly, and knead at 95° C. for 15 minutes;

[0067] (4) Add expanded graphite and zinc borate, stir evenly, and knead at 95° C. for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com