Cuo-ceo2 catalyst for water gas shift reaction and preparation method thereof

A technology for transformation reactions and catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Effect, high activity, heat resistance enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

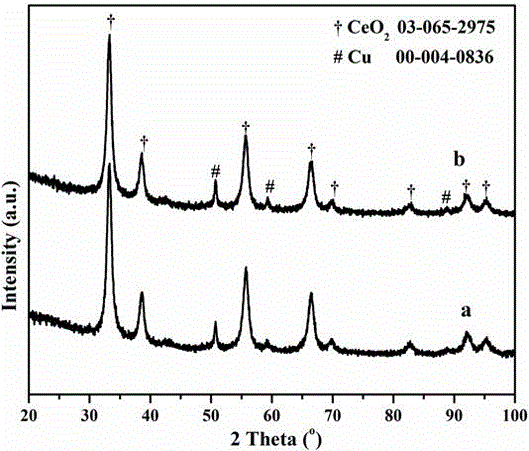

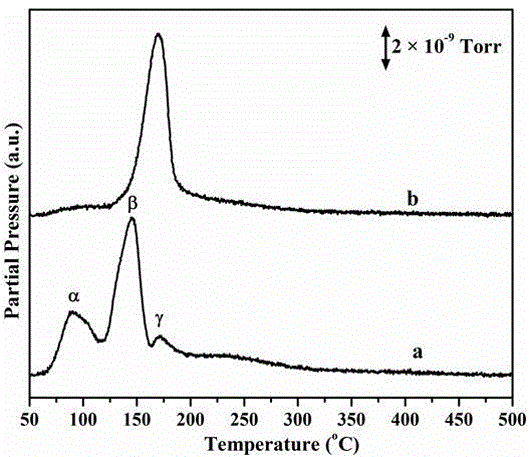

Examples

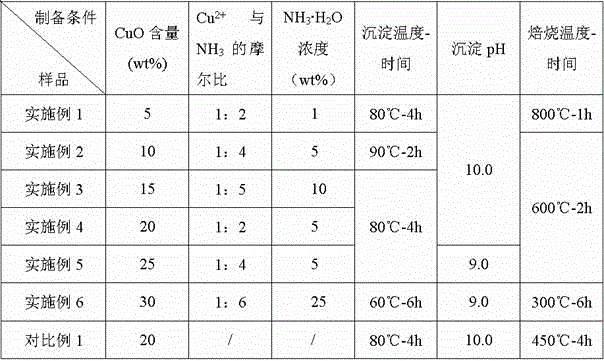

Embodiment 1

[0024] A CuO-CeO for water gas shift reaction 2 The preparation method of catalyst, comprises the steps:

[0025] 1) Weigh Ce(NO 3 ) 3 ·6H 2 O43.422g, add 200mL deionized water to dissolve, and make Ce 3+ Salt solution; KOH16.833g was weighed and made into 600mL alkali solution; under mechanical stirring, the Ce 3+ Salt solution and alkali solution were added dropwise to 80°C deionized water at the same time until the pH value of the solution was 10. After mixing and reacting, it was aged for 6 hours, cooled and centrifuged to obtain a precipitate, which was washed 8 times to remove impurity ions, and then in CeO was obtained by drying at 120°C for 12 hours 2 carrier;

[0026] 2) Weigh Cu(NO 3 ) 2 ·3H 2 O0.635g was dissolved in 26.3mL deionized water to make Cu 2+ Salt solution; measure 0.4ml of 25wt% ammonia water and dissolve it in 10ml of deionized water to make an ammonia solution; at room temperature, add the ammonia solution dropwise to Cu 2+ In salt solution,...

Embodiment 2

[0030] A CuO-CeO for water gas shift reaction 2 The preparation method of catalyst, comprises the steps:

[0031] 1) Weigh Ce(NO 3 ) 3 ·6H 2 O43.422g, add 200mL deionized water to dissolve, and make Ce3+ Salt solution; KOH16.833g was weighed and made into 600mL alkali solution; under mechanical stirring, the Ce 3+ Salt solution and alkali solution were added dropwise to 80°C deionized water at the same time until the pH value of the solution was 10. After mixing and reacting, it was aged for 6 hours, cooled and centrifuged to obtain a precipitate, which was washed 8 times to remove impurity ions, and then in CeO was obtained by drying at 120°C for 12 hours 2 carrier;

[0032] 2) Weigh Cu(NO 3 ) 2 ·3H 2 O1.005g was dissolved in 41.6mL deionized water to make Cu 2+ Salt solution; measure 1.3ml of 25wt% ammonia water and dissolve it in 6.3ml of deionized water to make an ammonia solution; at room temperature, add the ammonia solution dropwise to Cu 2+ In salt solution, ...

Embodiment 3

[0036] A CuO-CeO for water gas shift reaction 2 The preparation method of catalyst, comprises the steps:

[0037] 1) Weigh Ce(NO 3 ) 3 ·6H 2 O43.422g, add 200mL deionized water to dissolve, and make Ce 3+ Salt solution; KOH16.833g was weighed and made into 600mL alkali solution; under mechanical stirring, the Ce 3+ Salt solution and alkali solution were added dropwise to 80°C deionized water at the same time until the pH value of the solution was 10. After mixing and reacting, it was aged for 6 hours, cooled and centrifuged to obtain a precipitate, which was washed 8 times to remove impurity ions, and then in CeO was obtained by drying at 120°C for 12 hours 2 carrier;

[0038] 2) Weigh Cu(NO 3 ) 2 ·3H 2 O1.599g was dissolved in 66.1mL deionized water to make Cu 2+ Salt solution; Measure 3ml of 25wt% ammonia water and dissolve it in 4.5ml of deionized water to make an ammonia solution; at room temperature, add the ammonia solution dropwise to Cu 2+ In salt solution, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com