Preparation method of cu-based water gas shift reaction catalyst

A transformation reaction, water gas technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor performance reproducibility, environmental pollution, etc., and achieve stable structure and performance, high activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

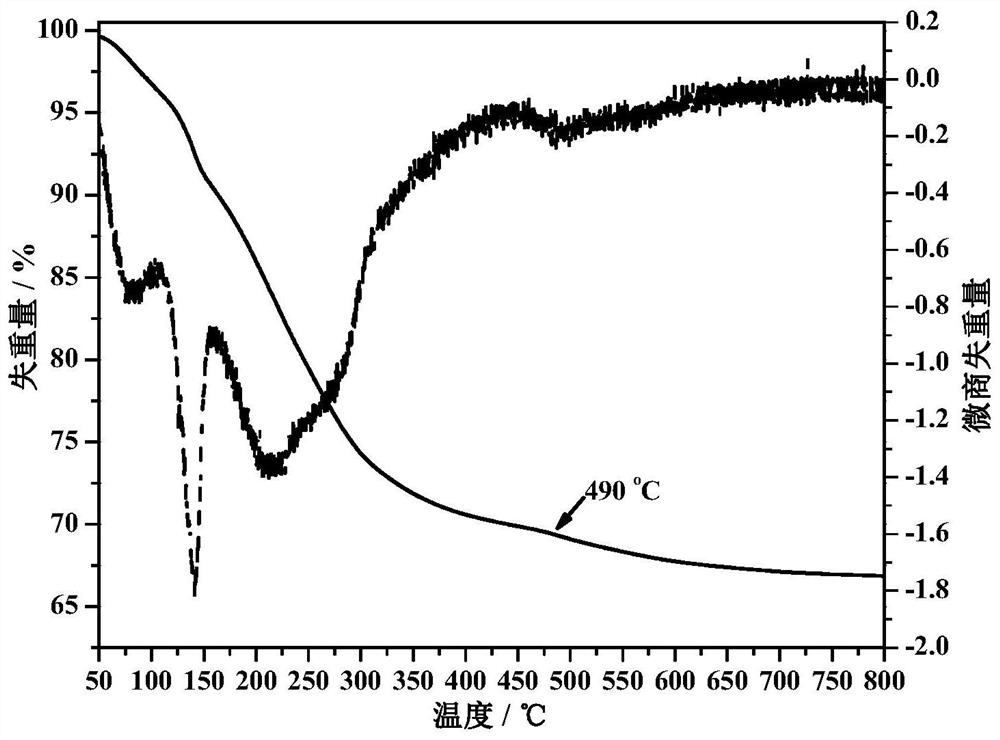

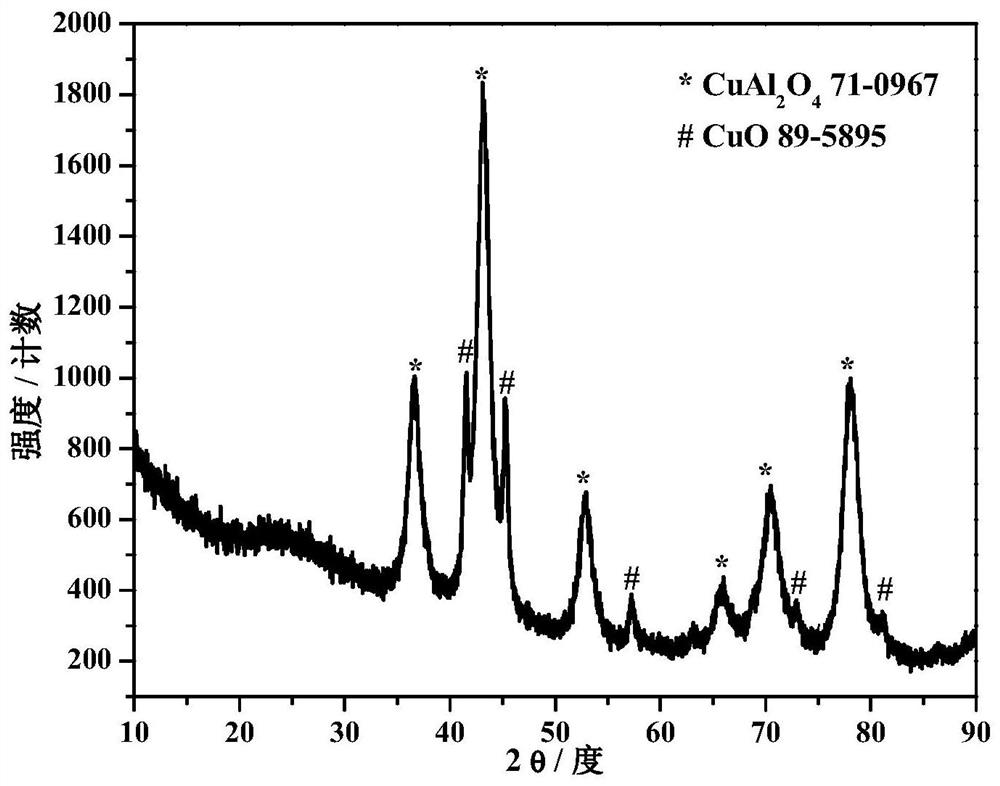

Embodiment 1

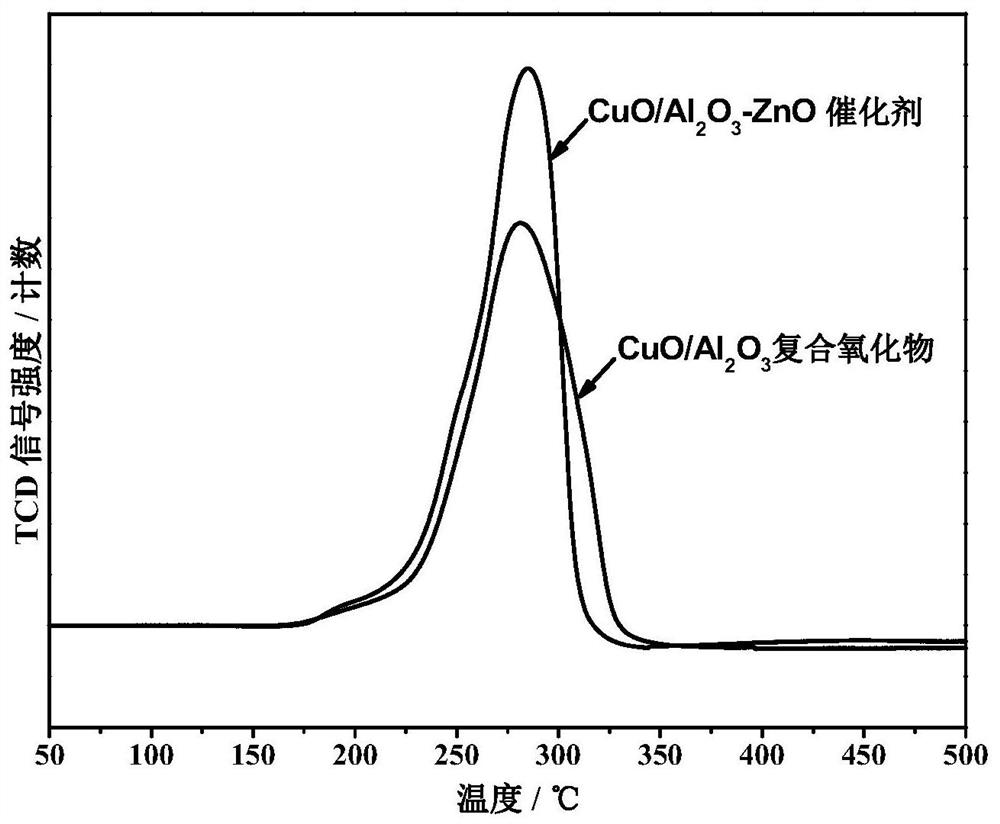

[0032] Accurately weigh the mass to be 18.2248g Cu(NO 3 ) 2 ·3H 2 O and 66.2234g Al(NO 3 ) 3 9H 2 O was prepared into 400ml mixed brine solution and 55.0138g Na 2 CO 3 Add dropwise to 500ml of deionized water; use the co-current co-precipitation method, control the temperature of the water bath at 80°C, and mechanically stir, and the pH value of the reaction system is 7.5. After the above solution was added dropwise, the reaction was continued for 3 h under stirring conditions. Naturally cooled, the precipitate was centrifuged, washed, dried at 110°C for 10h, and calcined in a static air atmosphere at 500°C for 6h to obtain CuO-CuAl-containing 2 o 4 / Al 2 o 3 of composite oxides.

[0033] Weigh 8g containing CuO-CuAl 2 o 4 / Al 2 o 3 composite oxide, add 25ml Zn(NO 3 ) 2 solution (0.87mol / L), impregnated and adsorbed at room temperature for 3h, dried at 110°C for 10h, and roasted in a static air atmosphere at 400°C for 3h to obtain CuO-CuAl-containing 2 o 4 / ...

Embodiment 2

[0037] Accurately weigh the mass to be 17.1960g Cu(NO 3 ) 2 ·3H 2 O and 68.7399g Al(NO 3 ) 3 9H 2 O was prepared by dissolving 400ml of mixed salt solution and 29.1273g of KOH in 500ml of deionized water; using the co-current co-precipitation method, controlling the temperature of the water bath at 80°C, stirring mechanically, and the pH of the reaction system was 8.0. After the salt solution was added dropwise, the reaction was continued for 2 h under stirring conditions. Naturally cooled, the precipitate was centrifuged, washed, dried at 110°C for 10h, and calcined in a static air atmosphere at 800°C for 2h to obtain CuO-CuAl-containing 2 o 4 / Al 2 o 3 of composite oxides.

[0038] Weigh 8g containing CuO-CuAl 2 o 4 / Al 2 o 3 composite oxide, add 20ml Zn(OAc) 2 solution (1.23mol / L), impregnated and adsorbed at room temperature for 3h, dried at 110°C for 10h, and roasted in a static air atmosphere at 400°C for 2h to obtain CuO-CuAl-containing 2 o 4 / Al 2 o 3...

Embodiment 3

[0041] Accurately weigh 12.0856g Cu(NO 3 ) 2 ·3H 2 O and 37.5152g Al(NO 3 ) 3 9H 2 O prepared into 400ml mixed salt solution (Cu 2+ :Al 3+ =1:2) and 31.7802g Na 2 CO 3 Dissolve in 500ml of deionized water; use the co-current co-precipitation method, control the temperature of the water bath at 80°C, and mechanically stir, the pH of the reaction system is 7.0. After the salt solution was added dropwise, the reaction was continued for 4 h under stirring conditions. Naturally cooled, the precipitate was centrifuged, washed, dried at 110°C for 10h, and roasted in a static air atmosphere at 650°C for 2h to obtain CuO-CuAl-containing 2 o 4 / Al 2 o 3 of composite oxides.

[0042] Weigh 8g containing CuO-CuAl 2 o 4 / Al 2 o 3 composite oxide, add 25ml Zn(OAc) 2 solution (1.31mol / L), impregnated and adsorbed at room temperature for 3h, dried at 110°C for 10h, and roasted in a static air atmosphere at 450°C for 3h to obtain CuO-CuAl-containing 2 o 4 / Al 2 o 3 -ZnO t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com