A multi-fiber blended sound-absorbing material

A sound-absorbing material and multi-fiber technology, used in sound-emitting equipment, textiles, papermaking, non-woven fabrics, etc. The preparation process is simple and the effect of aging is not easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

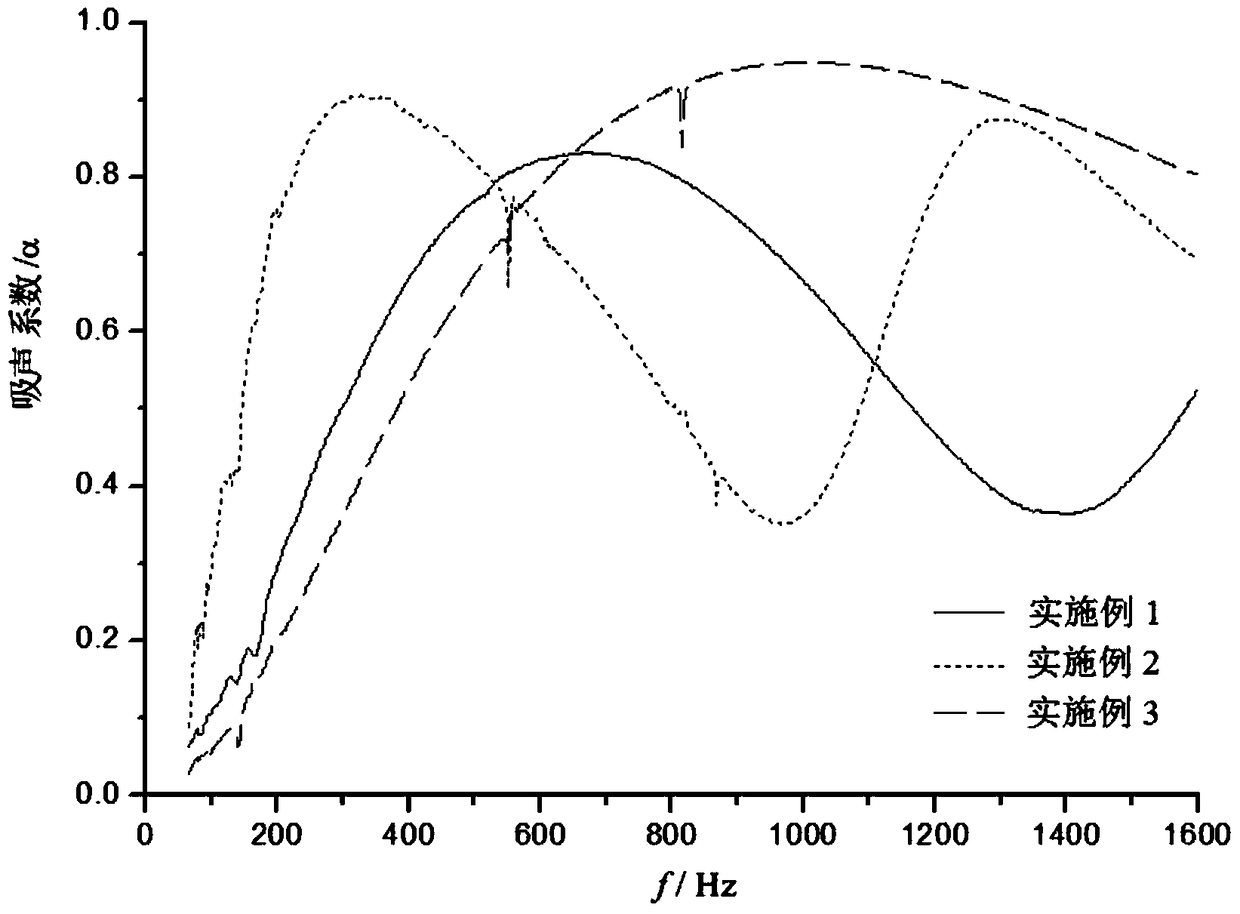

Embodiment 1

[0030] A multi-fiber blended sound-absorbing material, which is composed of aluminum fibers and organic composite polymer fibers, is characterized in that the material of the aluminum fibers is pure aluminum with a diameter of 100 μm, and the material of the organic composite polymer fibers is polyester fibers (inside) And polypropylene fiber (outer layer), the diameter is 50μm, the mixing ratio is (mass of aluminum fiber: quality of organic composite polymer fiber) 1:2, and the surface density of fiber mat is 1000g / m 2 , the thickness of the fiber mat is 3cm, and the thickness of the air layer in the back cavity is 15cm when used.

[0031] The preparation method of the multi-fiber blended sound-absorbing material comprises the following steps:

[0032] (1) Use high-quality pure aluminum raw materials to scrape into aluminum fiber filaments of uniform thickness;

[0033] (2) The aluminum fiber filaments are cut into aluminum fiber short fibers of the same length by a fiber cu...

Embodiment 2

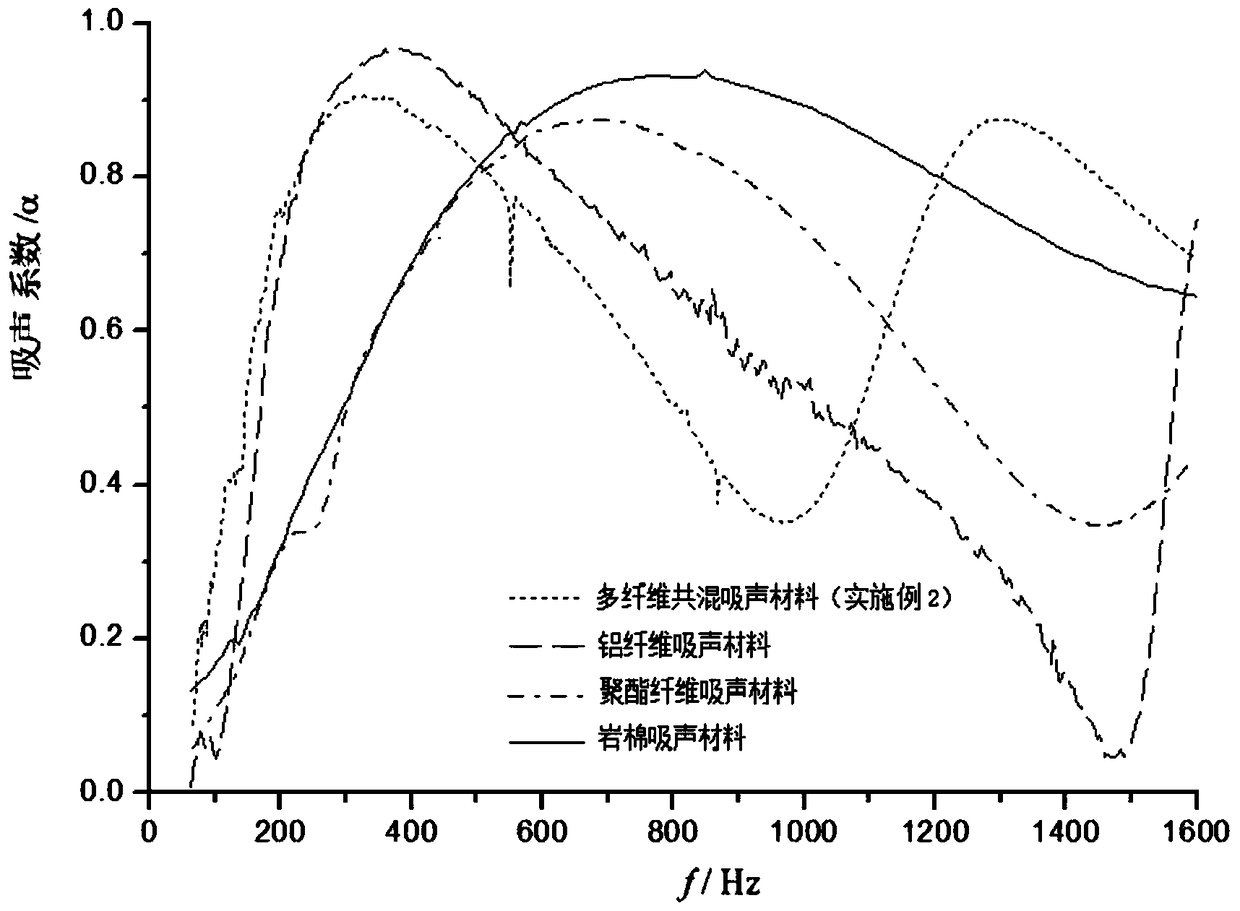

[0039] The multi-fiber blended sound-absorbing material is prepared in the same manner as in Example 1, but the difference is that the diameter of the aluminum fiber is 50 μm, the diameter of the organic composite polymer fiber is 20 μm, and the mixing ratio is (quality of aluminum fiber: organic composite high Molecular fiber mass) 2:1, fiber mat surface density 1500g / m 2 .

[0040] This embodiment is mainly designed for low-frequency equipment such as high-voltage reactors and main transformers. However, in order to meet the needs of low-frequency noise reduction for the above-mentioned equipment, this product gives up the absorption rate of part of the mid-to-high frequency band noise, and the sound absorption coefficient drops significantly from 300Hz.

Embodiment 3

[0042] The multi-fiber blended sound-absorbing material is prepared in the same manner as in Example 1, but the difference is that the diameter of the aluminum fiber is 50 μm, the diameter of the organic composite polymer fiber is 50 μm, and the mixing ratio is (quality of aluminum fiber: organic composite high Molecular fiber mass) 2:1, fiber mat surface density 1200g / m 2 .

[0043] Embodiment 3 is mainly aimed at intermediate frequency equipment such as fans with a noise frequency between 800 and 2000 Hz. The results show that the sound absorption coefficient of embodiment 3 is always above 0.7 between 600 and 1600 Hz.

[0044] According to the national standard GB / T18696.2-2002 "Measurement of Sound Absorption Coefficient and Acoustic Impedance in Acoustic Impedance Tube Part 1: Transfer Function Method", the examples 1 to 3 measured by the Danish B&K4206 dual-microphone impedance measurement system The sound absorption coefficient of the multi-fiber blended sound-absorbin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com