Acoustic stealth covering layer and application thereof

A sound-absorbing covering layer and covering layer technology are applied in the field of sound stealth, which can solve the problems that the low-frequency sound-absorbing performance is difficult to be improved, and the low-frequency sound-absorbing effect is difficult to achieve, and achieve good broadband sound-absorbing performance and low-frequency sound-absorbing performance. Good, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

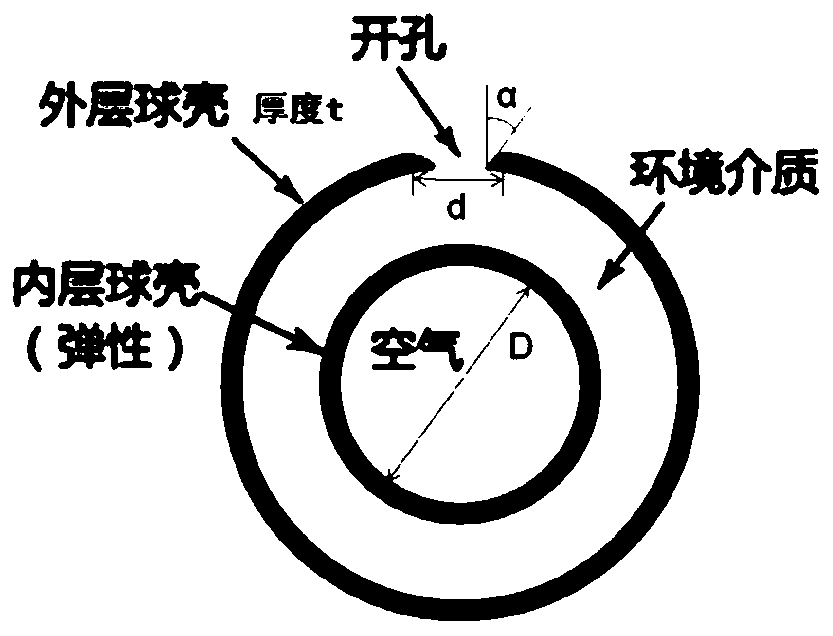

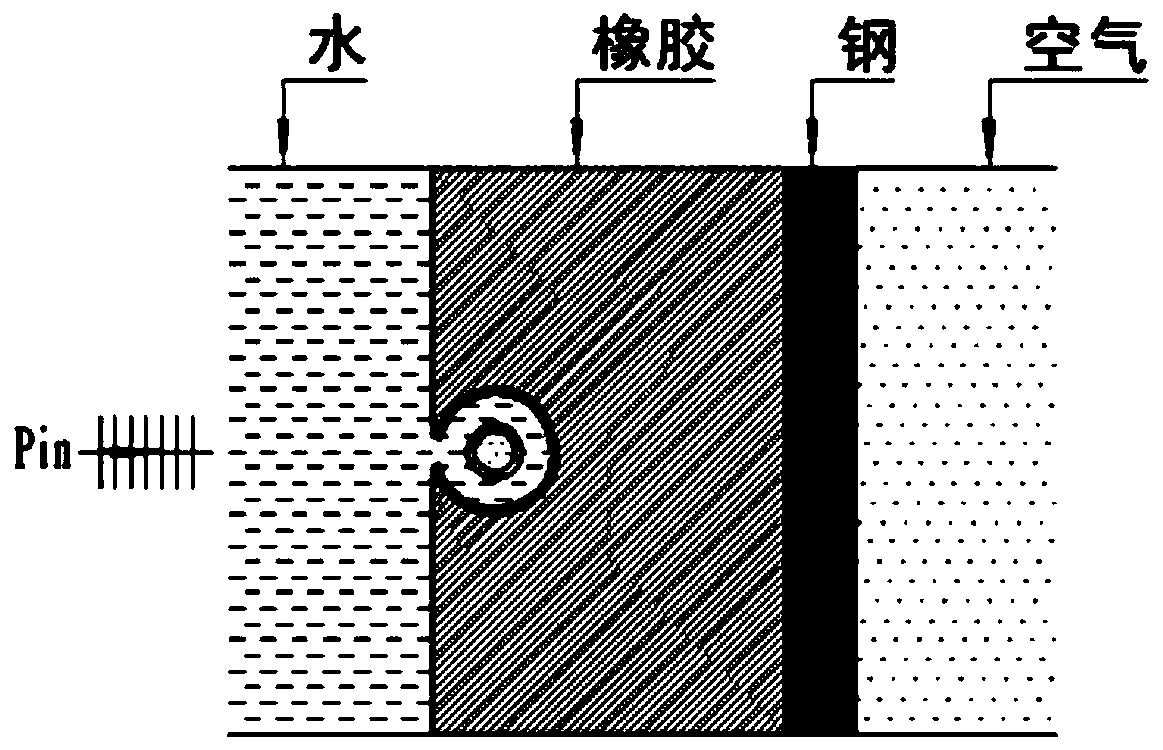

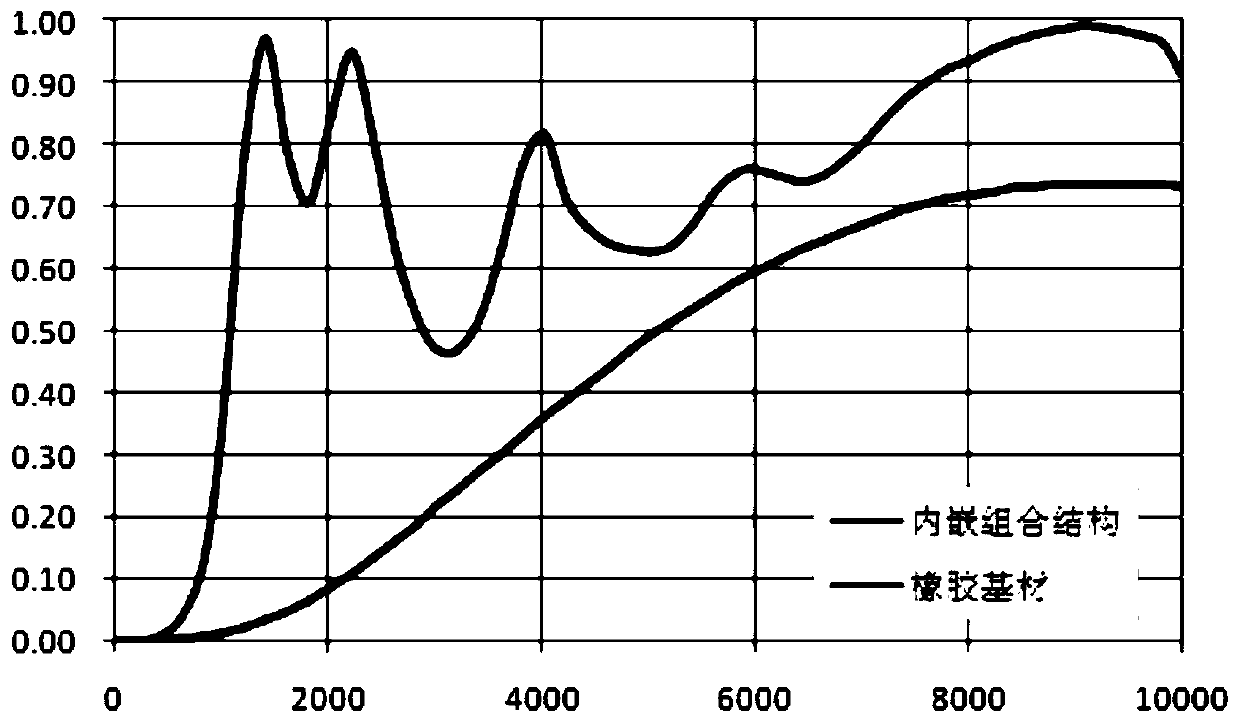

Embodiment 1

[0036] An acoustic stealth coating covering the surface of an underwater vehicle, the schematic diagram of the section is as follows figure 2 As shown, the thickness of the steel plate is 10mm, and the acoustic stealth covering layer is composed of nitrile rubber with a thickness of 50mm and a combined sound-absorbing structure embedded in the outer surface of the nitrile rubber. A spherical cavity with a diameter of 24.6mm (the center of the ball is 12.3mm away from the rubber surface), and a steel spherical shell with an outer diameter of 24.6mm and a thickness of 0.3mm is built in the cavity. On the side, a hole with a diameter of 3mm is opened without chamfering. The hole can lead the water in the environment to the inside of the steel spherical shell, and a nitrile with an inner diameter of 12.0mm and a thickness of 0.3mm is arranged in the steel spherical shell. Rubber ball, the air in the rubber ball is atmospheric pressure, the outer steel spherical shell and the inne...

Embodiment 2

[0039]An acoustic stealth covering layer adopting a single-size combined sound-absorbing structure, covering the surface of an underwater vehicle, the thickness of the outer steel plate of the aircraft is 10mm, and the acoustic stealth covering layer is made of nitrile rubber with a thickness of 50mm and embedded in nitrile rubber The outer surface is composed of a combined sound-absorbing structure. The outer surface of nitrile rubber is in contact with water. A spherical cavity with a diameter of 11.6mm is dug on the surface of the rubber (the center of the ball is 5.8mm from the rubber surface), and an outer cavity is built into the 11.6mm cavity. For a steel spherical shell with a diameter of 11.6mm and a thickness of 0.4mm, a hole with a diameter of 3mm is opened on the side of the steel spherical shell facing the outer surface of the nitrile rubber, and the chamfer of the hole is 10 degrees. The water is led to the inside of the steel spherical shell, and there is a nitri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com