Underwater sound absorption structure of damping lining hierarchical honeycomb perforated plate

A perforated plate and inner lining technology, applied in the direction of sound-generating devices, layered products, metal layered products, etc., can solve the problems of poor low-frequency sound absorption performance, heavy quality, poor load-bearing performance, etc., and achieve excellent low-frequency sound absorption Performance, improving low-frequency sound absorption performance, and ensuring the effect of structural load-bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

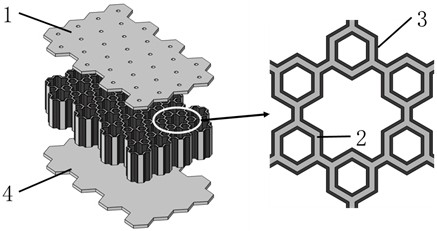

[0040] The central perforation diameter of the perforated upper panel is 3mm, the perforated upper panel node perforation diameter is 2mm, the perforated upper panel thickness is 3mm, the hierarchical honeycomb layer core height is 60mm, the central honeycomb side length is 30mm, the node honeycomb side length is 8mm, and the thickness of the central honeycomb damping inner lining is 3mm. The thickness of the node honeycomb damping lining is 3mm.

Embodiment 2

[0042] The central perforation diameter of the perforated upper panel is 2mm, the perforated diameter of the nodes of the perforated upper panel is 3mm, the thickness of the perforated upper panel is 2mm, the height of the hierarchical honeycomb layer core is 50mm, the side length of the central honeycomb is 15mm, the length of the node honeycomb side is 6mm, and the thickness of the central honeycomb damping lining is 2mm. The thickness of the node honeycomb damping lining is 1mm.

Embodiment 3

[0044] The central perforation diameter of the perforated upper panel is 5mm, the perforated diameter of the node of the perforated upper panel is 5mm, the thickness of the perforated upper panel is 1mm, the height of the hierarchical honeycomb layer core is 30mm, the side length of the central honeycomb is 45mm, the length of the node honeycomb side is 20mm, and the thickness of the central honeycomb damping inner lining is 4mm. The thickness of the node honeycomb damping lining is 5mm.

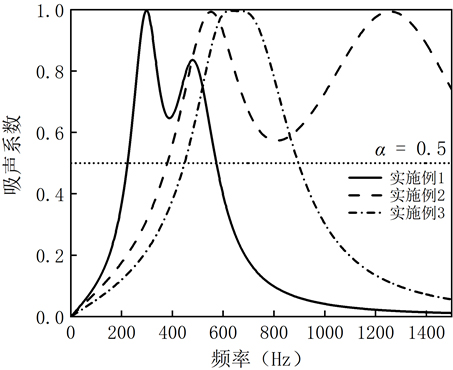

[0045] see figure 2 , the Helmholtz resonance phenomenon at low frequencies can achieve perfect sound absorption in a certain frequency range. The acoustic impedance characteristics of the structure are improved by pasting the damping lining layer on the side wall of the hierarchical honeycomb resonant cavity, and the rubber layer provides additional acoustic resistance and acoustic capacity, forming a Helmholtz-like resonance, making the present invention realize underwater perfect low-fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com