Sound-absorbing structure of photosensitive resin material

A photosensitive resin and sound-absorbing technology, which is applied in the direction of sound-generating devices and instruments, can solve the problems of greatly affecting sound-absorbing performance, consuming sound energy, and unfavorable promotion and use, so as to improve the low-frequency sound-absorbing effect and increase the sound-absorbing coefficient and the effect of sound resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

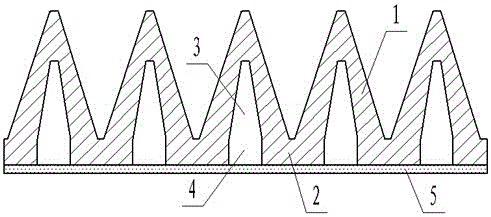

[0016] A sound-absorbing structure of a photosensitive resin material, comprising wedges 1 and a bottom plate 2, the wedges 1 are arrayed on one surface of the bottom plate 2, and the bottom plate 2 and the wedges 1 are formed by integral 3D printing of photosensitive resin. The bottom plate 2 is provided with a perforation 4 , and a wedge cavity 3 is provided inside the wedge 1 . The wedge cavity 3 corresponds to the perforation 4 , and a micro-perforated plate 5 is provided on the other surface of the bottom plate 2 .

[0017] In this embodiment, the material of the micro-perforated plate 5 is made of steel plate, aluminum plate, hard plastic plate, etc. The diameter of the micro-holes on the micro-perforated plate 5 is 0.1-0.8mm, and the perforation rate of the micro-perforated plate 5 is 0.3 ~0.5%.

[0018] Further, the thickness of the bottom plate 2 is 5-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com