Technology for preparing composite hole structure broadband sound absorption material through waste plastic

A technology for waste plastics and sound-absorbing materials, which is used in the environmentally friendly recycling of various waste polymers and solid waste treatment. , the sound absorption material is thick and other problems, to achieve the effect of easy installation, wide sound absorption frequency range, low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

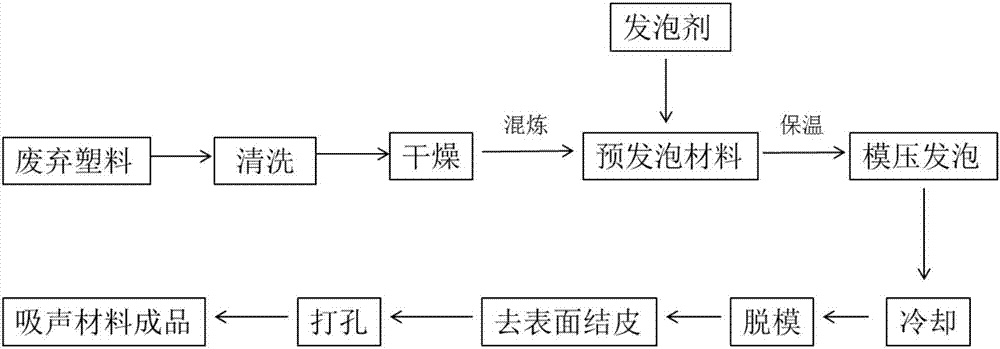

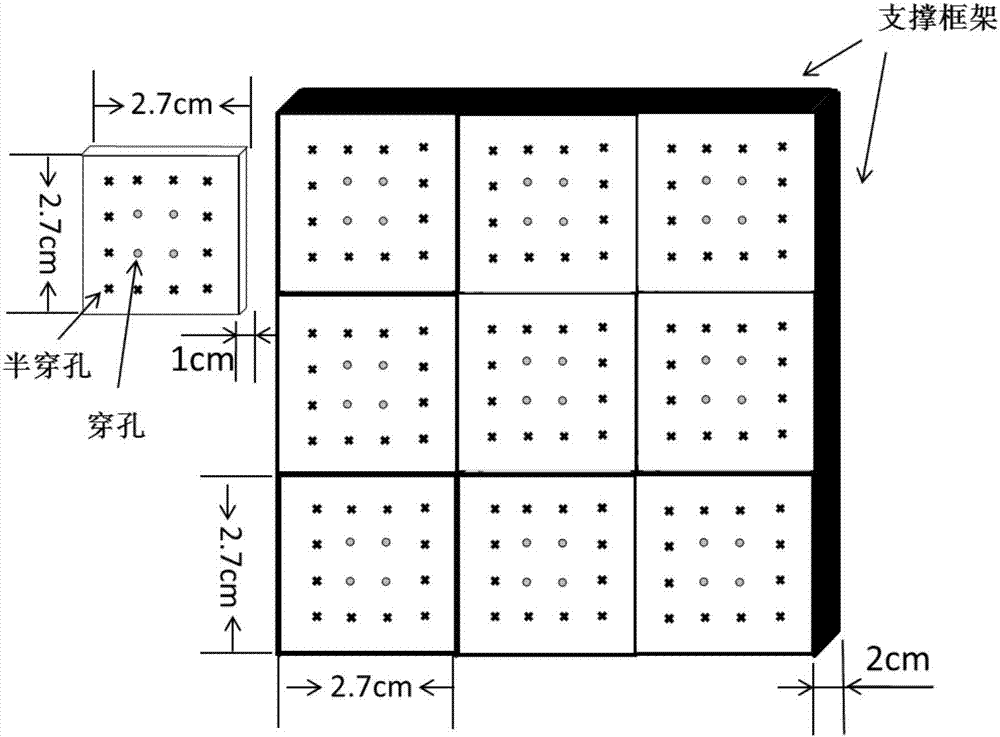

[0023] according to figure 1 The flow chart uses waste agricultural mulching film as raw material, washes it with water, and then air-dries it naturally for later use. Mix 3.6 grams of mulch film with 0.054 grams of azodicarbonamide at 160°C. After the mixing is uniform, the mixed material is made into a flat sheet similar to the shape of the mold. After preheating the mold at 180°C for 10 minutes, the compounded material was placed in the mold and foamed for 40 minutes. After foaming, let it cool naturally to below 100°C and demould. Cut off the surface crust layer of the demoulded material to expose the pore structure, and punch 4 perforations with a diameter of 0.3 cm and uniform gaps and 12 concave holes with a depth of 5 mm on the material, and install the air layer behind it. 10mm sealed rigid bracket. In the frequency range of 200-6400Hz, the highest sound absorption coefficient can reach 0.99 (900Hz), the sound absorption peak width is about 500Hz, and the average ...

Embodiment 2

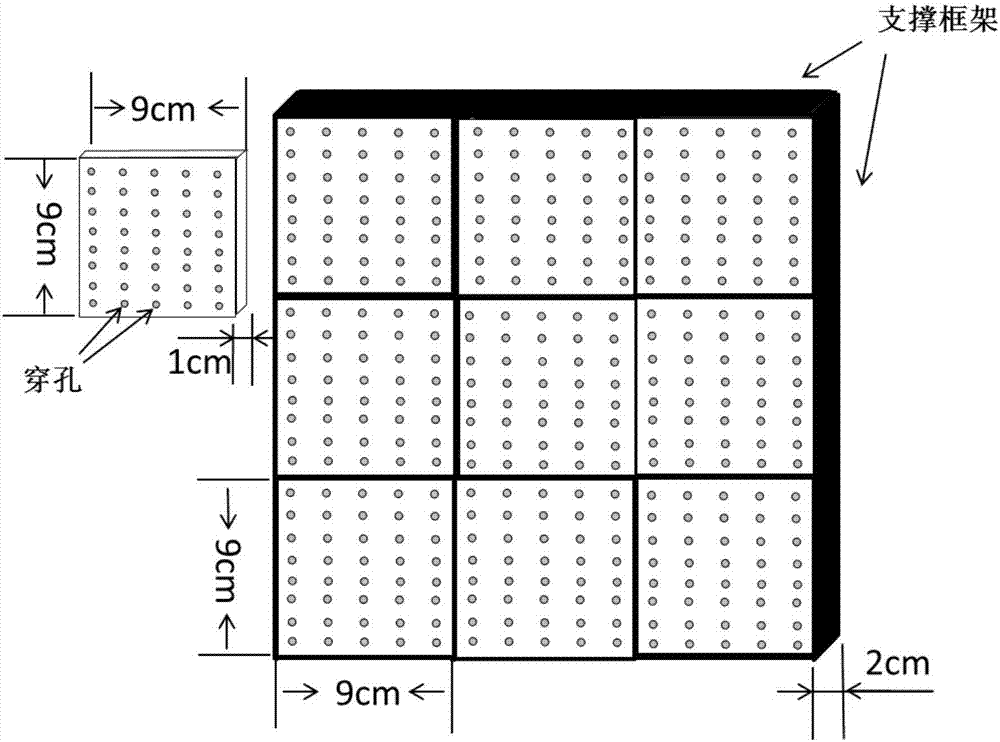

[0025] according to figure 1 The flow chart uses waste polyethylene plastics as raw materials, washes them with water, and then air-dries them naturally for later use. 40 g of polyethylene was kneaded with 0.60 g of azodicarbonamide at 160° C. for 2 minutes, and then the kneaded material was pressed into a flat sheet approximately in the shape of a mold. After the mold was preheated for 10 minutes at 180° C., the compounded material was placed in the mold and molded and foamed for 40 minutes. After foaming, let it cool naturally to below 100°C and demould. Peel off the surface crust layer of the demoulded material to expose the pore structure, and punch 40 perforations with a uniform gap and a diameter of 0.3 cm on the material, and install it on a sealed rigid support with a thickness of 10 mm behind the air layer. The highest sound absorption coefficient in the frequency range of 160-1280Hz can reach 0.99 (900Hz), the sound absorption peak width is about 600Hz, and the ave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com