Lightweight noise reduction composite foam material and method for preparing same

A composite foam and noise reduction technology, applied in the field of polymer materials, can solve the problems of large sound absorption coefficient, high low-frequency sound absorption coefficient, poor processing performance, etc., achieve wide applicable frequency range, improve low-frequency sound absorption, and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

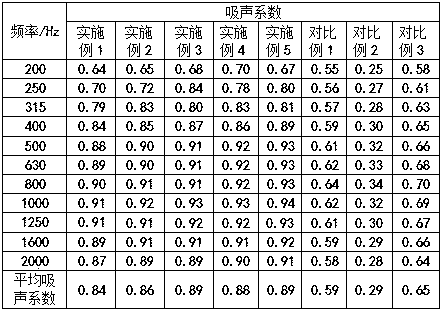

Examples

Embodiment 1

[0034] A preparation method of lightweight noise-reducing composite foam material, comprising the following steps:

[0035] (1) Put 42 parts of polyvinyl chloride, 7 parts of styrene-butadiene rubber, 10 parts of glass microspheres, 2 parts of glass fiber, 0.3 parts of lubricant, 0.2 parts of antioxidant, and 0.5 parts of coupling agent into a high-speed mixer. Evenly, control the speed of the high mixer to 700rpm, the temperature is 30°C, and mix for 15 minutes;

[0036] (2) Add 14 parts of rock wool, and then knead on an open kneading machine to obtain kneading materials. Control the speed of the kneading machine at 500 rpm, kneading temperature at 220°C, and kneading time for 10 minutes;

[0037] (3) Put the kneaded material into a mould, add 0.5 parts of foaming agent, heat up and foam in an oven, and control the temperature of the oven at 180-200°C to obtain the lightweight noise-reducing composite foam material.

Embodiment 2

[0039] A preparation method of lightweight noise-reducing composite foam material, comprising the following steps:

[0040] (1) Put 62 parts of polyvinyl chloride, 15 parts of styrene-butadiene rubber, 20 parts of glass beads, 8 parts of glass fiber, 0.8 parts of lubricant, 0.6 parts of antioxidant, and 0.9 parts of coupling agent into a high-speed mixer. Evenly, control the speed of the high mixer to 500rpm, the temperature is 60°C, and mix for 5 minutes;

[0041] (2) Add 23 parts of rock wool, and then knead on an open kneading machine to obtain kneading materials. Control the speed of the kneading machine at 700 rpm, kneading temperature at 180°C, and kneading time for 5 minutes;

[0042] (3) Put the kneaded material into a mold, add 1.5 parts of foaming agent, heat up and foam in an oven, and control the temperature of the oven at 175-195°C to obtain the lightweight noise-reducing composite foam material.

Embodiment 3

[0044] A preparation method of lightweight noise-reducing composite foam material, comprising the following steps:

[0045] (1) Put 50 parts of polyvinyl chloride, 11 parts of styrene-butadiene rubber, 15 parts of glass microspheres, 5 parts of glass fiber, 0.5 parts of lubricant, 0.4 parts of antioxidant, and 0.7 parts of coupling agent into a high-speed mixer. Evenly, control the speed of the high mixer to 500rpm, the temperature is 40°C, and mix for 10 minutes;

[0046] (2) Add 19 parts of rock wool, and then knead on an open kneading machine to obtain kneading materials. Control the speed of the kneading machine at 600 rpm, kneading temperature at 195°C, and kneading time for 8 minutes;

[0047] (3) Put the kneaded material into a mold, add 1 part of foaming agent, heat up and foam in an oven, and control the temperature of the oven at 175-190°C to obtain the lightweight noise-reducing composite foam material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com