Carbon nanotube/graphene oxide nanoribbon-polymer hybrid proton exchange membrane and preparation method thereof

A technology of graphene nanoribbons and proton exchange membranes, which is applied in the field of carbon nanotubes/graphene oxide nanoribbons-polymer hybrid proton exchange membranes and its preparation, can solve the problems of membrane performance restriction and reduction, and achieve proton conduction Increased efficiency, high size matching, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Preparation of carbon nanotubes / graphene oxide nanoribbons: disperse 0.1g of multi-walled carbon nanotubes in 35ml of sulfuric acid, stir for 1.5h; add 5mL of phosphoric acid, stir for 20min, while raising the temperature to 70 Add 0.2 g of potassium permanganate at a rate of h, and react at 70°C for 2 hours; then cool to room temperature, slowly add the reaction solution to 100 mL of 0°C, 3wt% hydrogen peroxide solution; centrifuge, wash with water, dialyze for a week, freeze Dry, get carbon nanotube / graphene oxide nanoribbon composite;

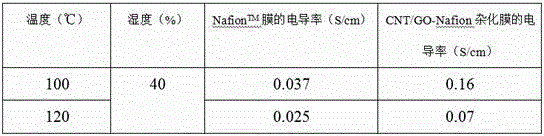

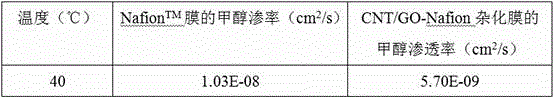

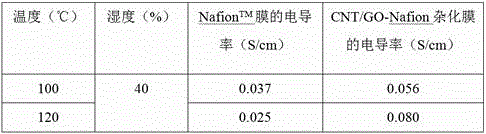

[0027] (2) Preparation of carbon nanotube / graphene oxide nanoribbon-polymer hybrid proton exchange membrane: add 1 mg carbon nanotube / graphene oxide nanoribbon to 4 ml of commercially available Nafion TM solution, sonicated for 20min; the resulting mixture was removed by rotary evaporation to remove most of the solvent, then 4ml of N,N-dimethylformamide was added, and rotary evaporation was continued for 20min; after standing for ...

Embodiment 2

[0035] (1) Preparation of carbon nanotubes / graphene oxide nanoribbons: disperse 0.1g of multi-walled carbon nanotubes in 35ml of sulfuric acid, stir for 1.5h; add 5mL of phosphoric acid, stir for 20min, while raising the temperature to 70 Add 0.1 g of potassium permanganate at a rate of h, and react at 70°C for 2 hours; then cool to room temperature, slowly add the reaction liquid to 100 mL of 0°C, 3wt% hydrogen peroxide solution; centrifuge, wash with water, dialyze for a week, freeze Dry, get carbon nanotube / graphene oxide nanoribbon composite;

[0036] (2) Preparation of carbon nanotube / graphene oxide nanoribbon-polymer hybrid proton exchange membrane: add 1 mg carbon nanotube / graphene oxide nanoribbon to 4 ml of commercially available Nafion TM solution, sonicated for 20min; the resulting mixture was removed by rotary evaporation to remove most of the solvent, then 4ml of N,N-dimethylformamide was added, and rotary evaporation was continued for 20min; after standing for 1....

Embodiment 3

[0044] (1) Preparation of carbon nanotubes / graphene oxide nanoribbons: disperse 0.1g of multi-walled carbon nanotubes in 35ml of sulfuric acid, stir for 1.5h; add 5mL of phosphoric acid, stir for 20min, while raising the temperature to 70 Add 0.3 g of potassium permanganate at a rate of h, react at 70°C for 3 hours; then cool to room temperature, slowly add the reaction solution to 100 mL of 0°C 3wt% hydrogen peroxide solution; centrifuge, wash with water, dialyze for a week, freeze Dry, get carbon nanotube / graphene oxide nanoribbon composite;

[0045] (2) Preparation of carbon nanotube / graphene oxide nanoribbon-polymer hybrid proton exchange membrane: add 1 mg carbon nanotube / graphene oxide nanoribbon to 4 ml of commercially available Nafion TM solution, sonicated for 20min; the resulting mixture was removed by rotary evaporation to remove most of the solvent, then 4ml of N,N-dimethylformamide was added, and rotary evaporation was continued for 20min; after standing for 1.5h,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com