Sulfonated oxidized graphene-silicon dioxide composition/polymer hybridized proton exchange membrane and preparation method thereof

A technology of proton exchange membrane and silicon dioxide, which is applied in the direction of electrochemical generators, final product manufacturing, fuel cell parts, etc., can solve the problems of reducing the proton conductivity of the membrane, which is no longer obvious, and achieves a good basis for industrial production , improve the selectivity, the effect of preparation condition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

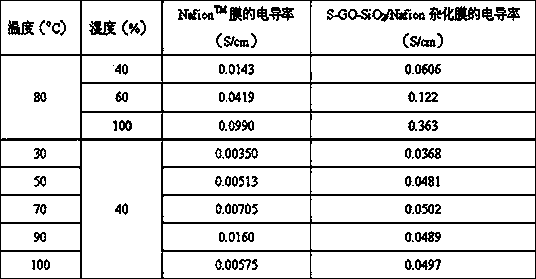

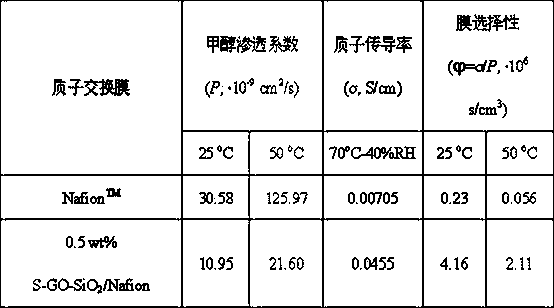

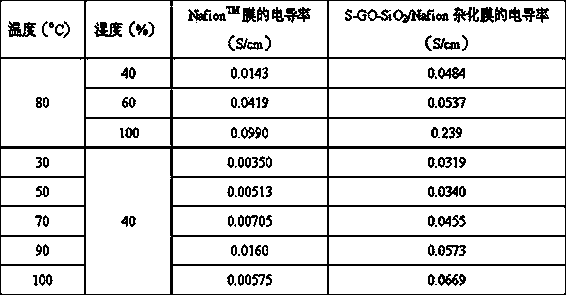

Embodiment 1

[0023] Disperse 100mg graphene oxide (GO) and 50mg dicyclohexylcarbodiimide (DCC) in 50ml 3-aminopropyltriethoxysilane (APTS) and sonicate for 3h to obtain a uniform dispersion; The case is placed at 70 o The reaction was carried out under C environment for 24 hours, and finally the product was obtained by repeating the steps of centrifugation-absolute ethanol washing and drying in a vacuum oven: APTS-modified GO (APTS-GO). Then, also under the condition of magnetic stirring, 140 mg APTS-GO was dispersed in a mixed solvent of 2.8 ml formic acid, 42 ml water and 308 ml absolute ethanol at 70 o C for 5d, and finally by repeating the steps of centrifugation-absolute ethanol washing several times, and drying in a vacuum oven to obtain the product: graphene oxide-silicon dioxide composite (GO-SiO 2 ). Then, 50 mg GO-SiO was obtained by ultrasonication for 3 h 2Uniform dispersion in 3.5g toluene; Subsequently, under the condition of condensing and refluxing, 1g γ-methacryloxyprop...

Embodiment 2

[0030] Disperse 100mg graphene oxide (GO) and 50mg dicyclohexylcarbodiimide (DCC) in 50ml 3-aminopropyltriethoxysilane (APTS) and sonicate for 3h to obtain a uniform dispersion; The case is placed at 70 o The reaction was carried out under C environment for 24 hours, and finally the product was obtained by repeating the steps of centrifugation-absolute ethanol washing and drying in a vacuum oven: APTS-modified GO (APTS-GO). Then, also under the condition of magnetic stirring, 140 mg APTS-GO was dispersed in a mixed solvent of 2.8 ml formic acid, 42 ml water and 308 ml absolute ethanol at 70 o C for 5d, and finally by repeating the steps of centrifugation-absolute ethanol washing several times, and drying in a vacuum oven to obtain the product: graphene oxide-silicon dioxide composite (GO-SiO 2 ). Then, 50 mg GO-SiO was obtained by ultrasonication for 3 h 2 Uniform dispersion in 3.5g toluene; Subsequently, under the condition of condensing and refluxing, 1g γ-methacryloxypro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com