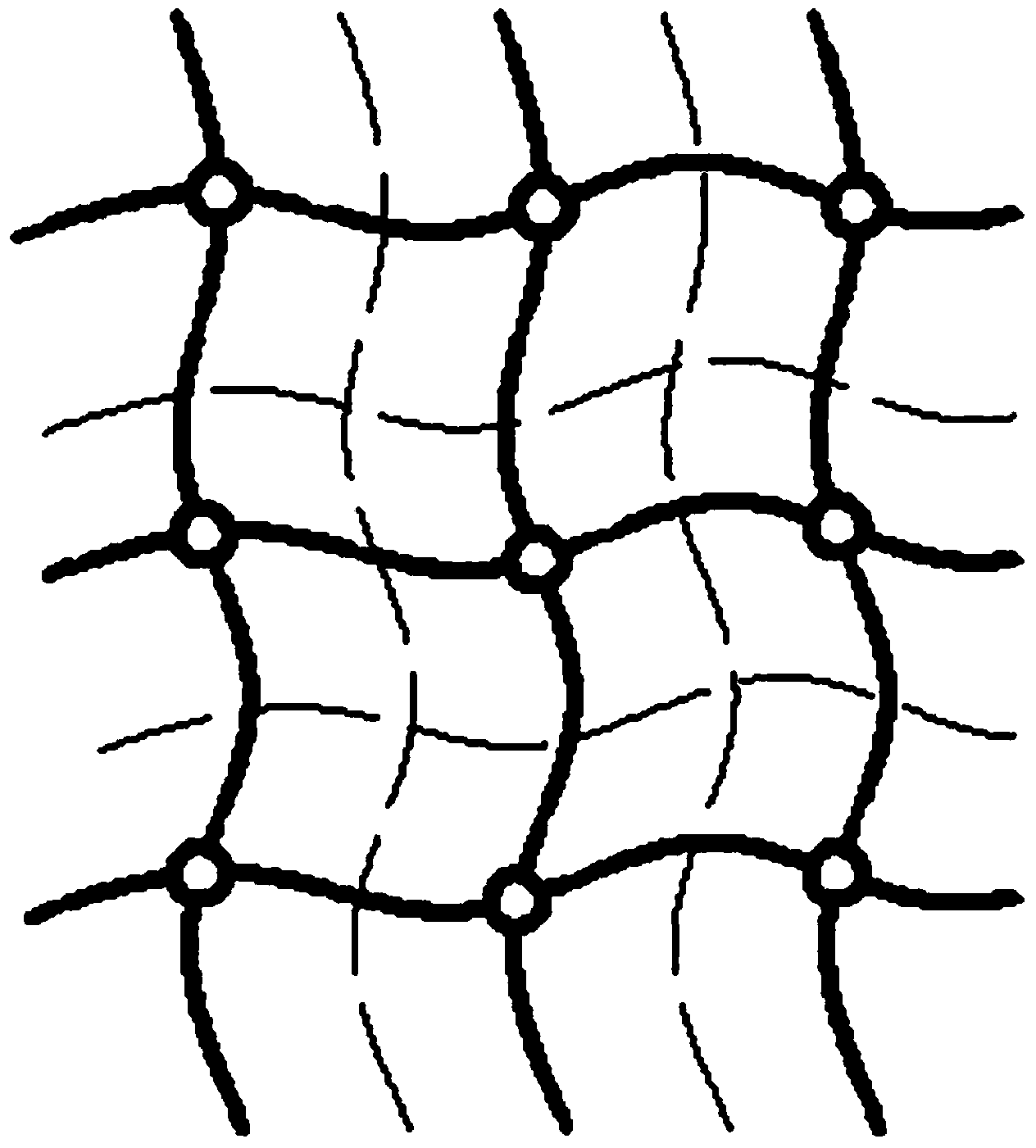

Semi-ipn (interpenetrating polymer network) proton exchange membrane and preparation method thereof

A technology of proton exchange membrane and network structure, applied in the field of semi-interpenetrating network structure proton exchange membrane and its preparation, can solve the problems of affecting the stability and service life of membrane structure, easy expansion and rupture of proton exchange membrane, increase of methanol permeability coefficient, etc. , to achieve reliable dimensional stability, improved selective permeability, and high selective permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

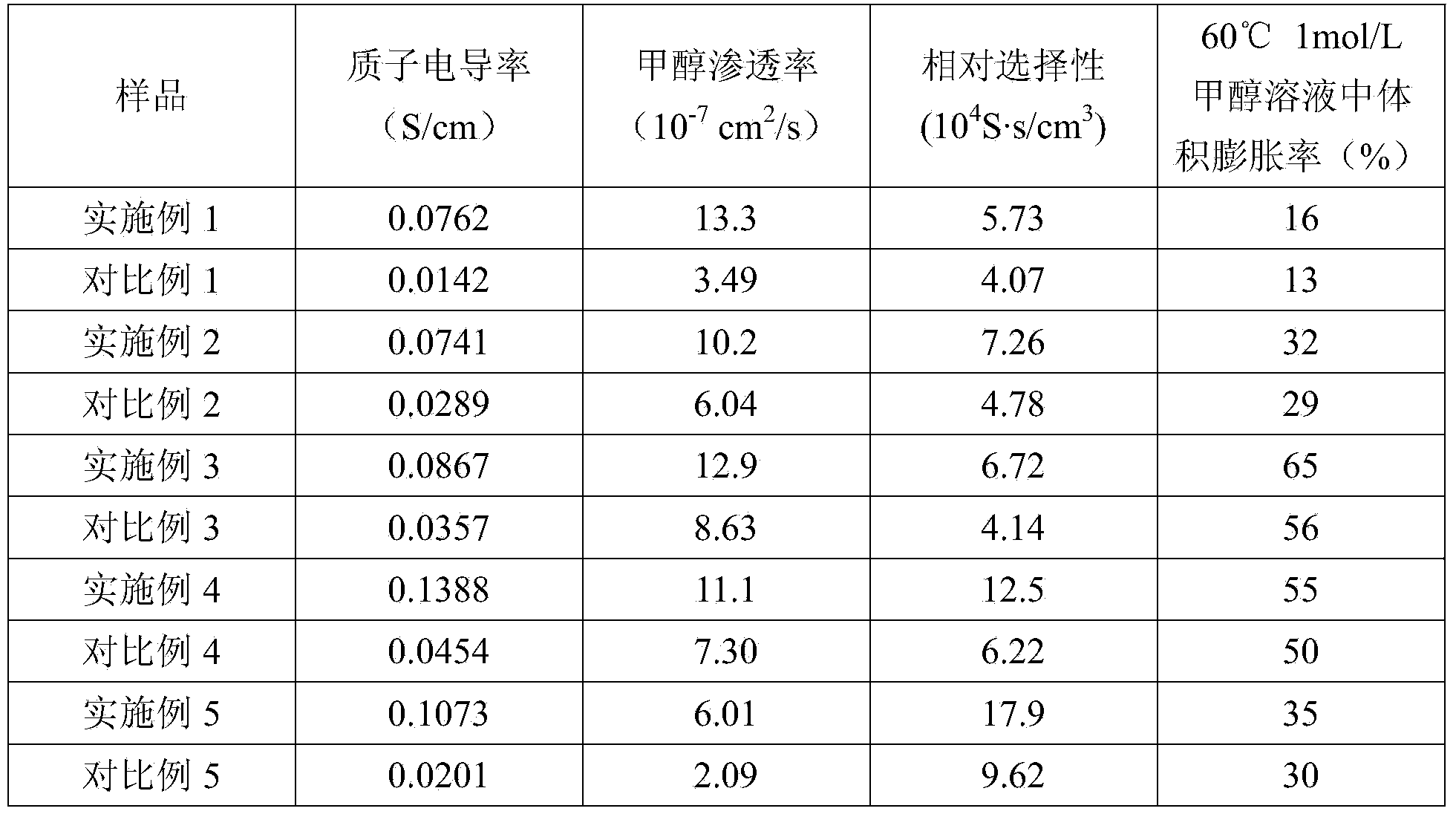

Examples

Embodiment 1

[0025] Preparation of semi-interpenetrating network structure sulfonated polyether ether ketone proton exchange membrane:

[0026] The sulfonated polyetheretherketone, AMPS, EGDMA, benzophenone with a sulfonation degree of 45% are dissolved in NMP with a mass ratio of 150:90:10:3 to form a solution with a total mass fraction of 5%; The resulting solution was poured into a petri dish, and then placed in an oven at 100°C to dry for 5 hours. At this time, the residual mass fraction of the solvent in the film with a gel state was 60%; Put it in the cross-linking instrument for 15 minutes, soak in dilute sulfuric acid and wash with water to obtain a semi-interpenetrating network structure sulfonated polyether ether ketone proton exchange membrane.

Embodiment 2

[0028] Preparation of semi-interpenetrating network structure sulfonated polyethersulfone proton exchange membrane:

[0029] Sulfonated polyethersulfone, AMPS, EGDMA, and benzophenone with a sulfonation degree of 55% are dissolved in DMAc at a mass ratio of 200:70:30:3 to form a solution with a total mass fraction of 12%; The solution was poured into a petri dish, and then dried in an oven at 80°C for 10 hours. At this time, the residual mass fraction of the solvent in the gel-state film was 30%; Placed in the coupler for 30 minutes, soaked in dilute sulfuric acid and washed with water to obtain a semi-interpenetrating network structure sulfonated polyethersulfone proton exchange membrane.

Embodiment 3

[0031] Preparation of semi-interpenetrating network structure sulfonated polyphenylene ether proton exchange membrane:

[0032] Sulfonated polyphenylene ether, AMPS, EGDMA, and benzophenone with a sulfonation degree of 70% were dissolved in NMP at a mass ratio of 250:90:10:3 to form a solution with a total mass fraction of 8%; the resulting The solution was poured into a petri dish, and then dried in an oven at 120°C for 4 hours. At this time, the residual solvent in the obtained gel-state film was 35%; Place in the instrument for 20 minutes, soak in dilute sulfuric acid and wash with water to obtain a semi-interpenetrating network structure sulfonated polyphenylene ether proton exchange membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com