Valve for the venting circuit of a liquid tank

a valve and liquid tank technology, applied in mechanical equipment, functional valve types, transportation and packaging, etc., can solve the problems of difficult parts, high manufacturing cost, and delay in opening of valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

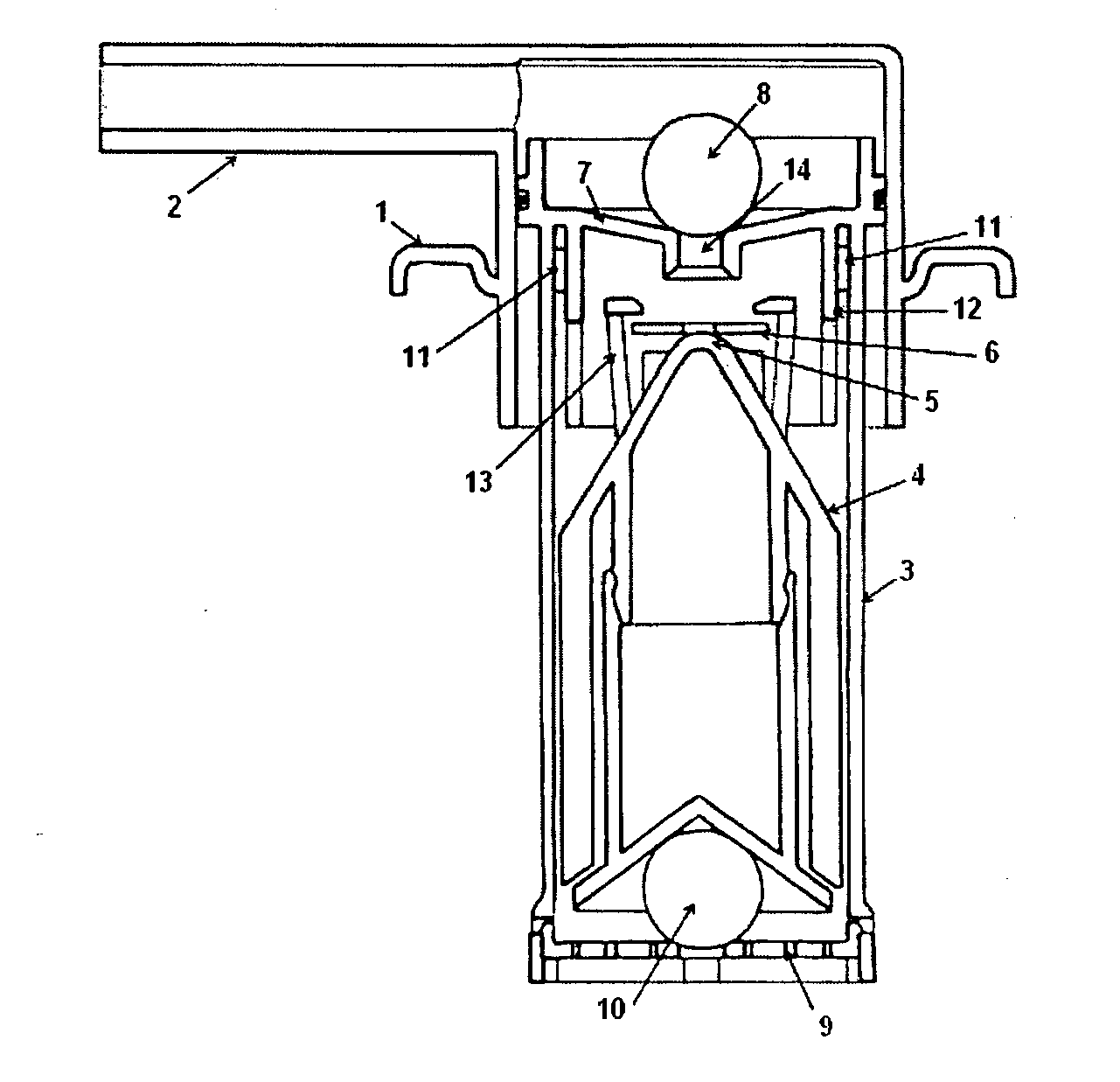

[0026] According to the invention, the needle has, at its upper end (or tip), a larger cross section than that of the aperture in the seal. Within the context of the invention, such a geometry means that the needle also has a cross section generally smaller than the cross section of the aperture in the seal. In this way, the seal can slide freely over a large portion of the needle, but is stopped in its travel by the tip. In this embodiment, the lower end of the needle (or its base for anchoring onto the head of the float) preferably has a cross section substantially equal (in shape and size) to that of the aperture of the seal so as to ensure perfect sealing in the closed position of the valve.

[0027] Consequently, a needle geometry that is very suitable for this embodiment is that in which the needle is essentially conical but is provided with a stop device at its tip. This stop device preferably has a conical lateral surface so as to make it easier to pass through the aperture of ...

second embodiment

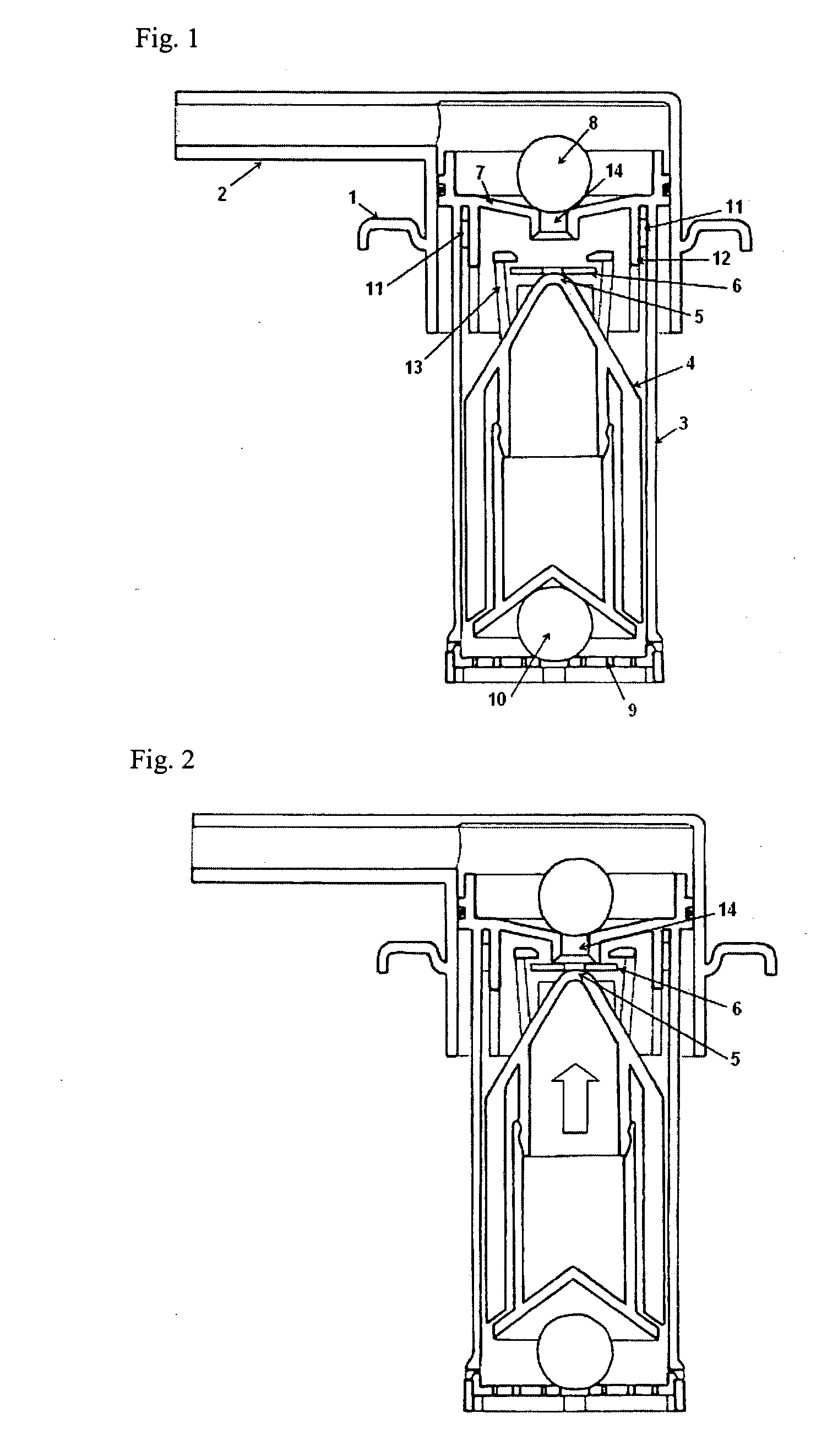

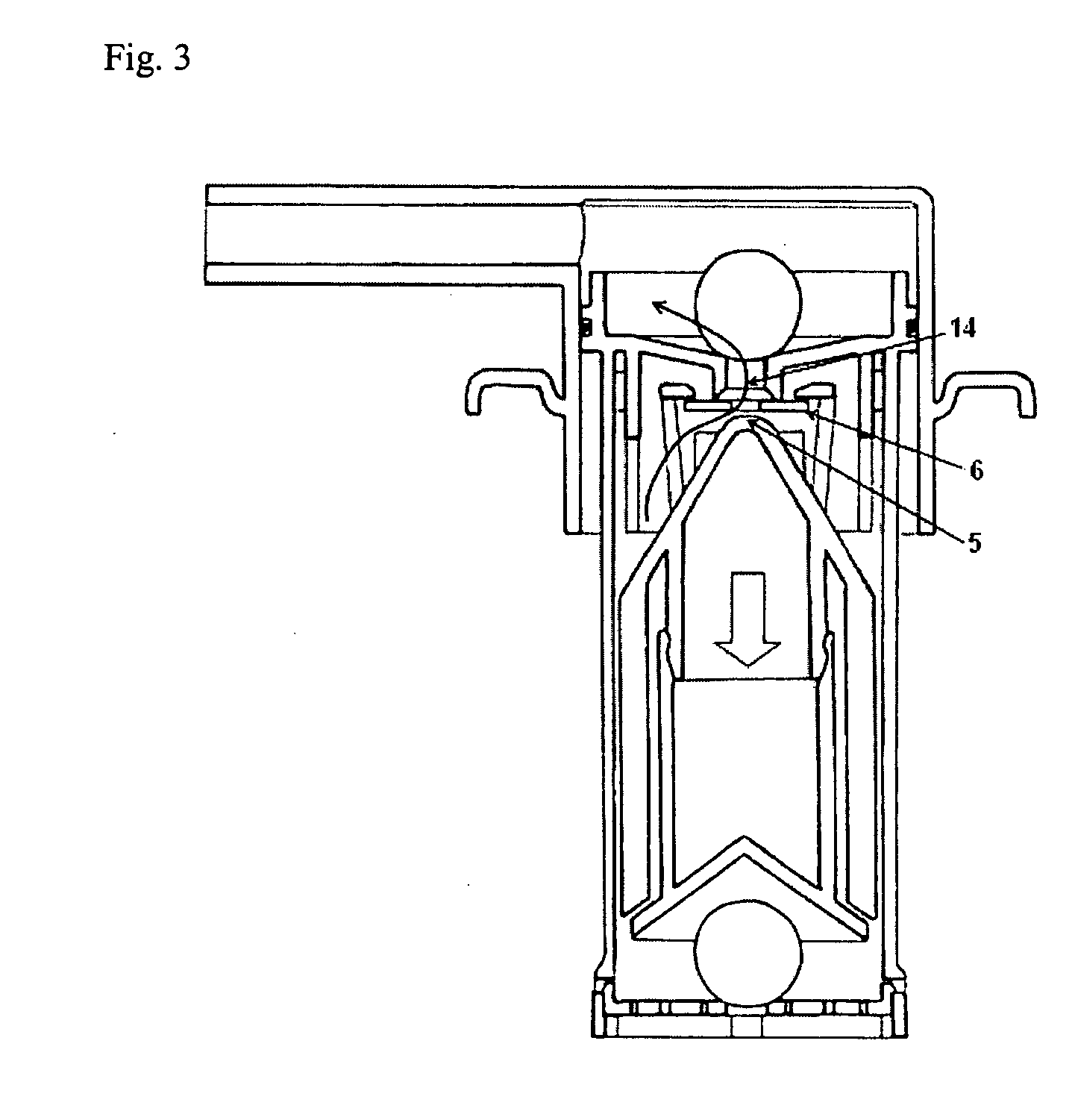

[0029] Thus, according to a preferred second embodiment of the invention, the head of the float comprises vertical hooked fingers that surround the needle and have an upper end higher than the needle. In this way, the seal can slide vertically between the hooked end of the fingers and a position where it bears on the head of the float. The term “hooked” is understood in fact to mean any shape allowing the seal to be retained. This shape may for example be that of an “L” on its tip.

[0030] In this embodiment, there are preferably at least three fingers so as to prevent the seal from leaking between two consecutive fingers. Most particularly preferably, there are at least four of them so as to limit this risk. These fingers are preferably placed symmetrically on the head of the float, and therefore in the form of a cross with equal branches when there are four of them. Most particularly preferably, these fingers guide the seal during its vertical travel, so as to minimize its lateral m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com