Green process for synthesizing adipic acid from cyclohexanone

A technology of adipic acid and cyclohexanone, applied in the production field of organic chemical raw materials, can solve problems such as harsh reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

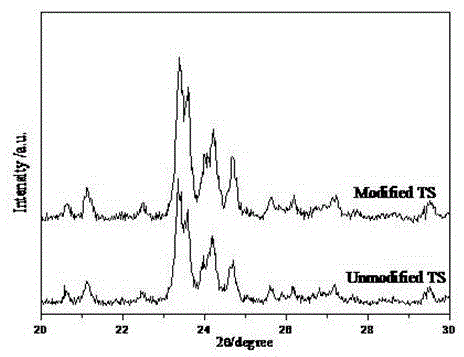

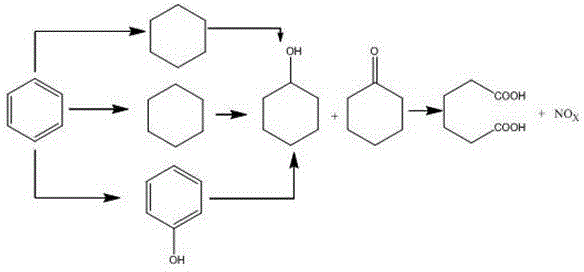

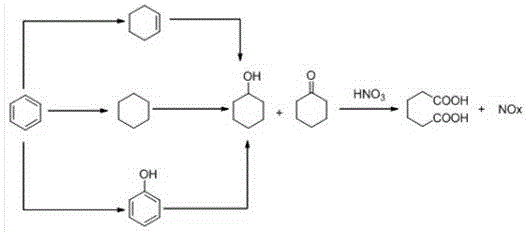

Image

Examples

Embodiment 1

[0020] Example 1: At a temperature of 100° C. and a pressure of 0.6 MPa, air is used as an oxidant, 400 g of cyclohexanone and 1.0 g of a catalyst are put into a reactor for reaction. The result of reacting for 9 hours was as follows: the conversion rate of cyclohexanone was 19.6%, and the selectivity of adipic acid was 78.8%.

Embodiment 2

[0021] Example 2: At a temperature of 90° C. and a pressure of 0.6 MPa, air is used as an oxidant, 400 g of cyclohexanone and 1.0 g of catalyst M2-TS are put into a reactor for reaction. The result of reacting for 9 hours was as follows: the conversion rate of cyclohexanone was 56.4%, and the selectivity of adipic acid was 91.5%.

Embodiment 3

[0022] Example 3: At a temperature of 100° C. and a pressure of 0.6 MPa, air is used as an oxidant, 400 g of cyclohexanone and 1.0 g of catalyst M3-TS are put into a reactor for reaction. The result of reacting for 9 hours was as follows: the conversion rate of cyclohexanone was 36.4%, and the selectivity of adipic acid was 78.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com