Functional transparent graphene heating film

A technology of ene heating film and functionalization, which is applied in the field of functionalized transparent graphene heating film, can solve the problems that cannot be realized at the same time, affect the appearance and user experience of the membrane group, and fail to realize the functionalization and functional application of the diaphragm, and achieve High sensitivity, realize the effect of therapeutic temperature monitoring and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

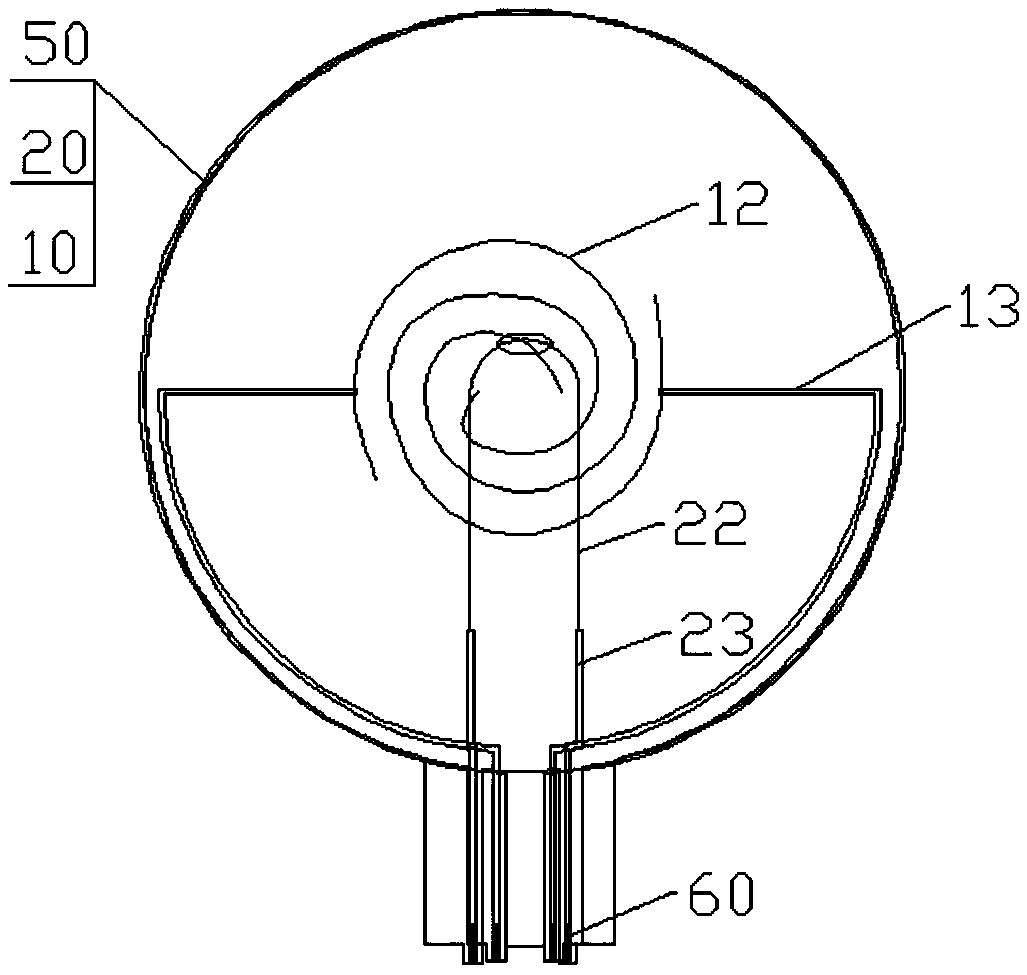

[0034] refer to figure 1 , Image 6 , Figure 7 and Figure 10 , a functionalized transparent graphene heating film, including a heating layer 10 and a temperature detection layer 20; The first electrode 13 of the graphene transparent heating film 12 is bonded on the first transparent polymer film 11; the temperature detection layer 20 includes a second transparent polymer film 21, a film temperature sensor 22 and a film temperature sensor The sensor 22 is connected to the second electrode 23 , the film temperature sensor 22 is glued on the second transparent polymer film 21 ; the heating layer 10 is laminated with the temperature detecting layer 20 .

[0035] The surface of the first transparent polymer film 11 that is bonded with the graphene transparent heating film 12 is the upper surface, and the other side is the lower surface; the surface of the second transparent polymer film 21 that is bonded with the film temperature sensor 22 is the upper surface. The other side...

Embodiment 2

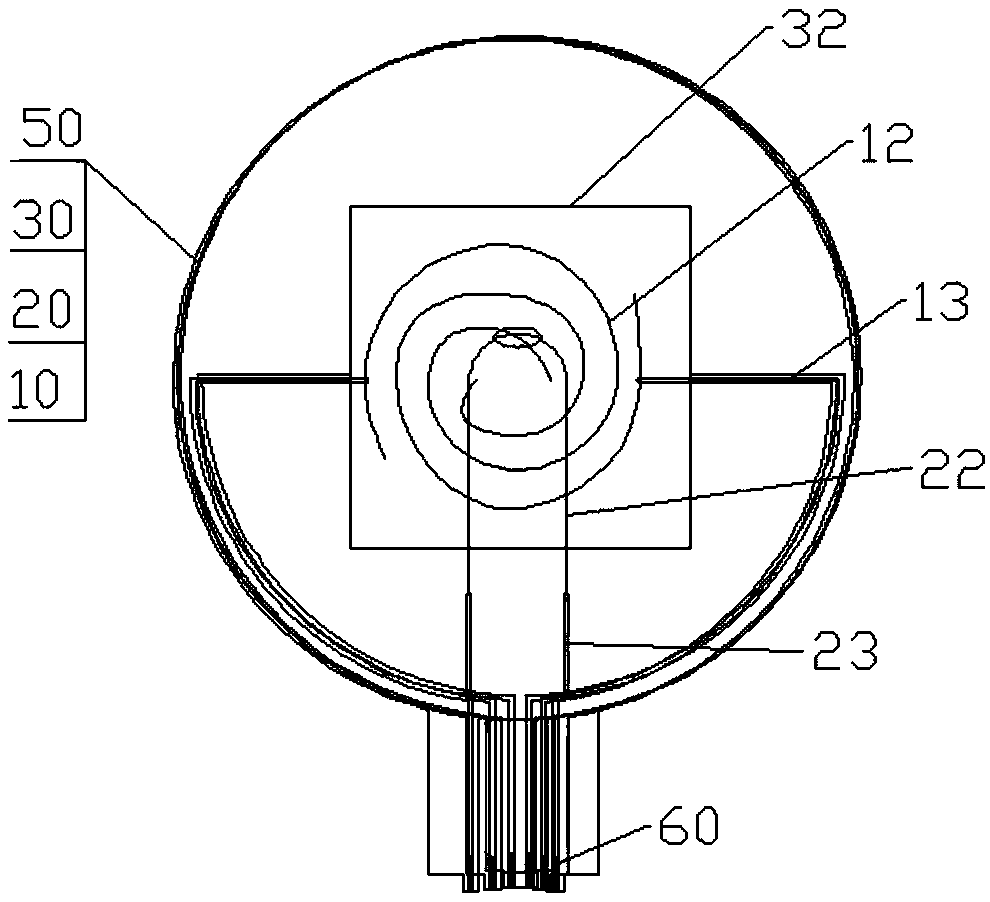

[0039] refer to figure 2 , Image 6 , Figure 7 , Figure 8 and Figure 10 , the technical solution of embodiment 2 is also provided with a pressure sensing layer 30 on the basis of the technical solution of embodiment 1, and the pressure sensing layer 30 includes a third transparent polymer film 31, a film pressure sensor 32 and a film pressure sensor 32 connected to the third electrode 33 , the pressure sensing layer 30 is laminated with the heating layer 10 and the temperature detecting layer 20 .

[0040] The surface of the third transparent polymer film 31 bonded with the pressure sensor is the upper surface, and the other surface is the lower surface. Adhesive is used to bond the upper surface of the second transparent polymer film 21 to the lower surface of the third transparent polymer film 31, the upper surface of the third transparent polymer film 31 is provided with an explosion-proof film 50, and the explosion-proof film 50 covers the pressure on the sensor. ...

Embodiment 3

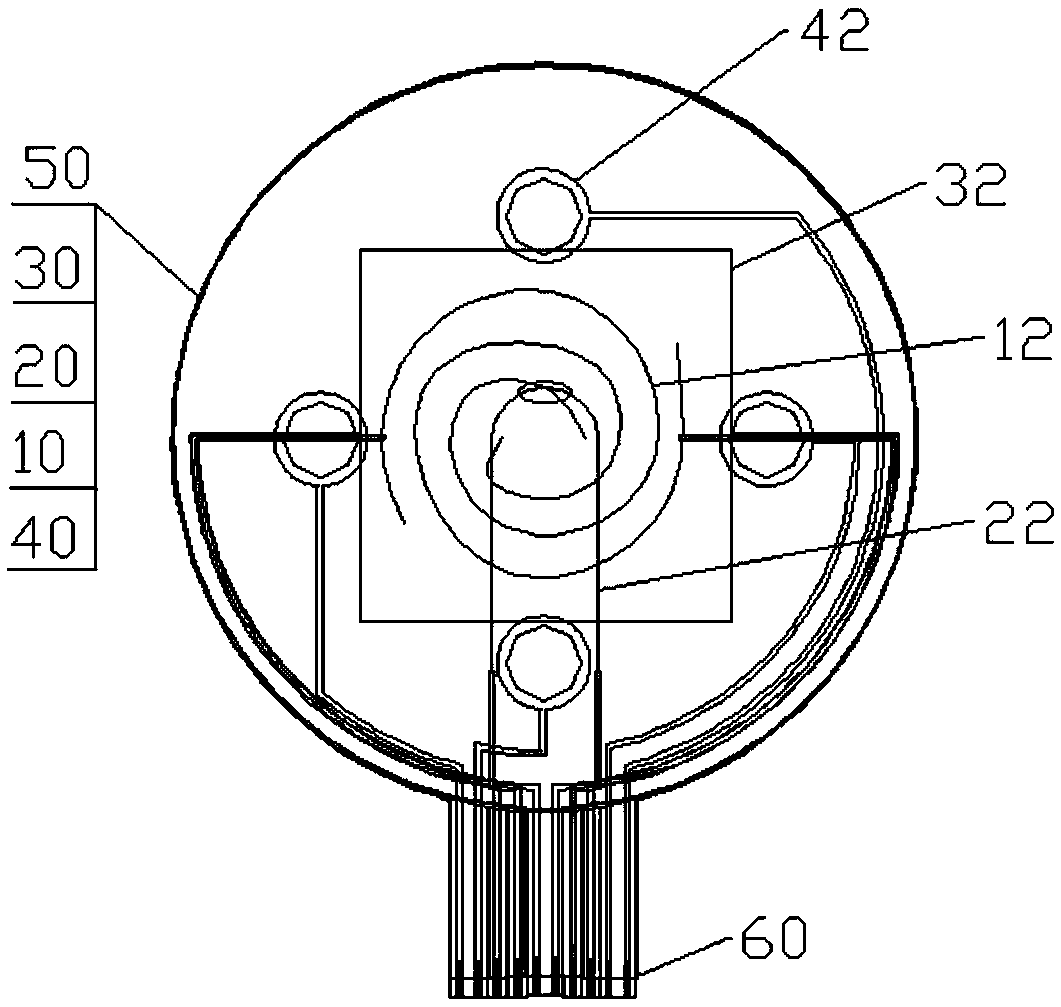

[0043] refer to image 3 as well as Figure 6 to Figure 12 , the technical solution of embodiment 3 is also provided with a base layer 40 on the basis of the technical solution of embodiment 2, and the base layer 40 includes a fourth transparent polymer film 41, an electrode sheet 42 and a fourth electrode 44 connected to the electrode sheet 42, The fourth transparent polymer film 41 is provided with an opening 43, and the electrode sheet 42 is installed in the opening 43; the heating layer 10, the temperature detection layer 20 and the pressure sensing layer 30 are stacked on the on the base layer 40. The diameter of the opening 43 is 4 millimeters, and the electrode sheet 42 includes a boss 421 and a base 422. The diameter of the boss 421 is 4 millimeters, and the diameter of the bottom 422 is 6 millimeters. The platform 421 passes through the opening 43 . The number of openings 43 and electrode sheets 42 is four.

[0044] The electrode sheet 42 is a copper sheet, the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com