A three-dimensional graphene sponge/Fe2O3 composite wave absorbing material and a preparation method thereof

A composite wave absorbing material and graphene sponge technology, applied in the field of wave absorbing materials, can solve the problems of time-consuming, high temperature of magnetic nanoparticles, complicated operation, etc., and achieve the effects of simple operation conditions, low density, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

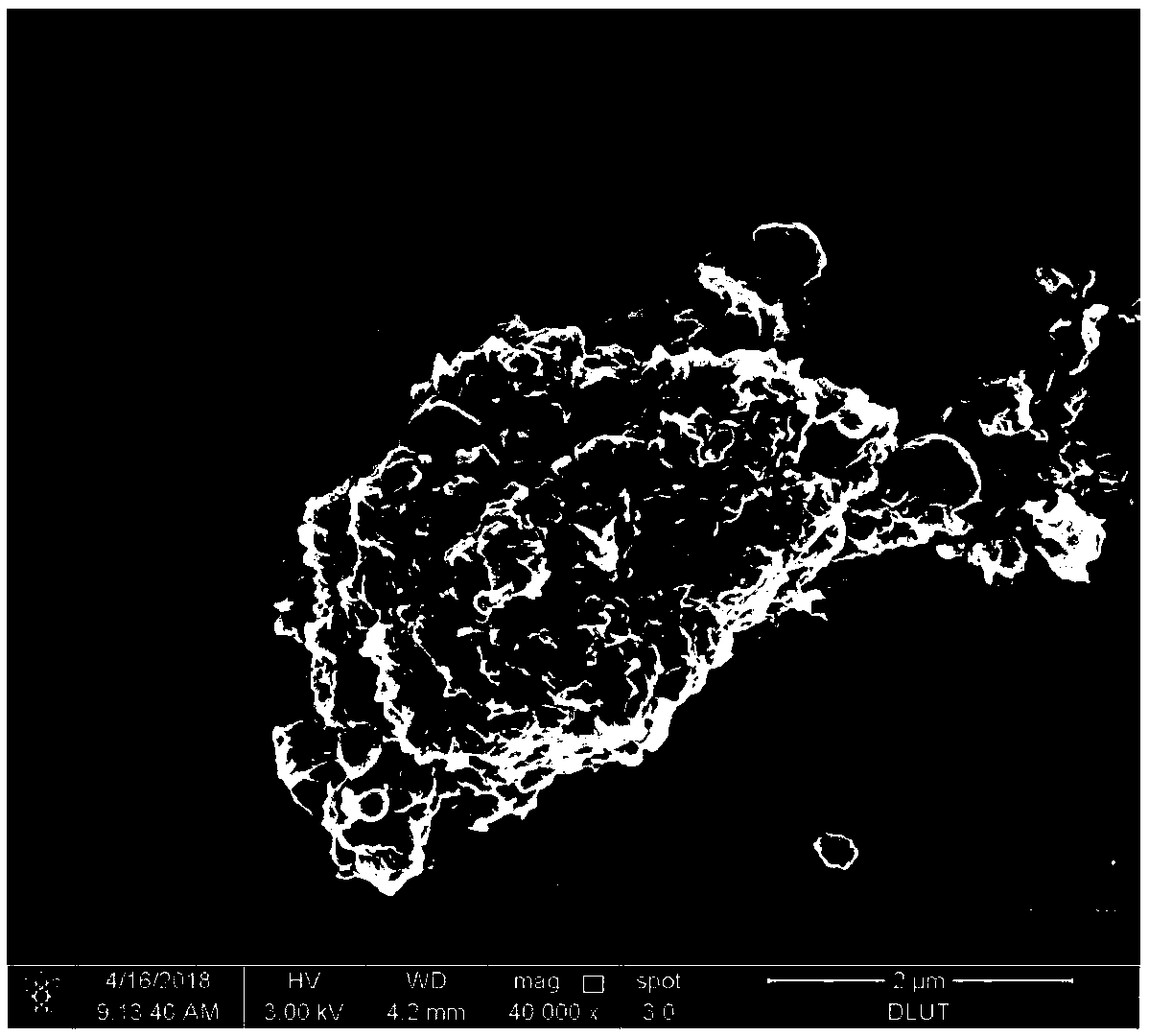

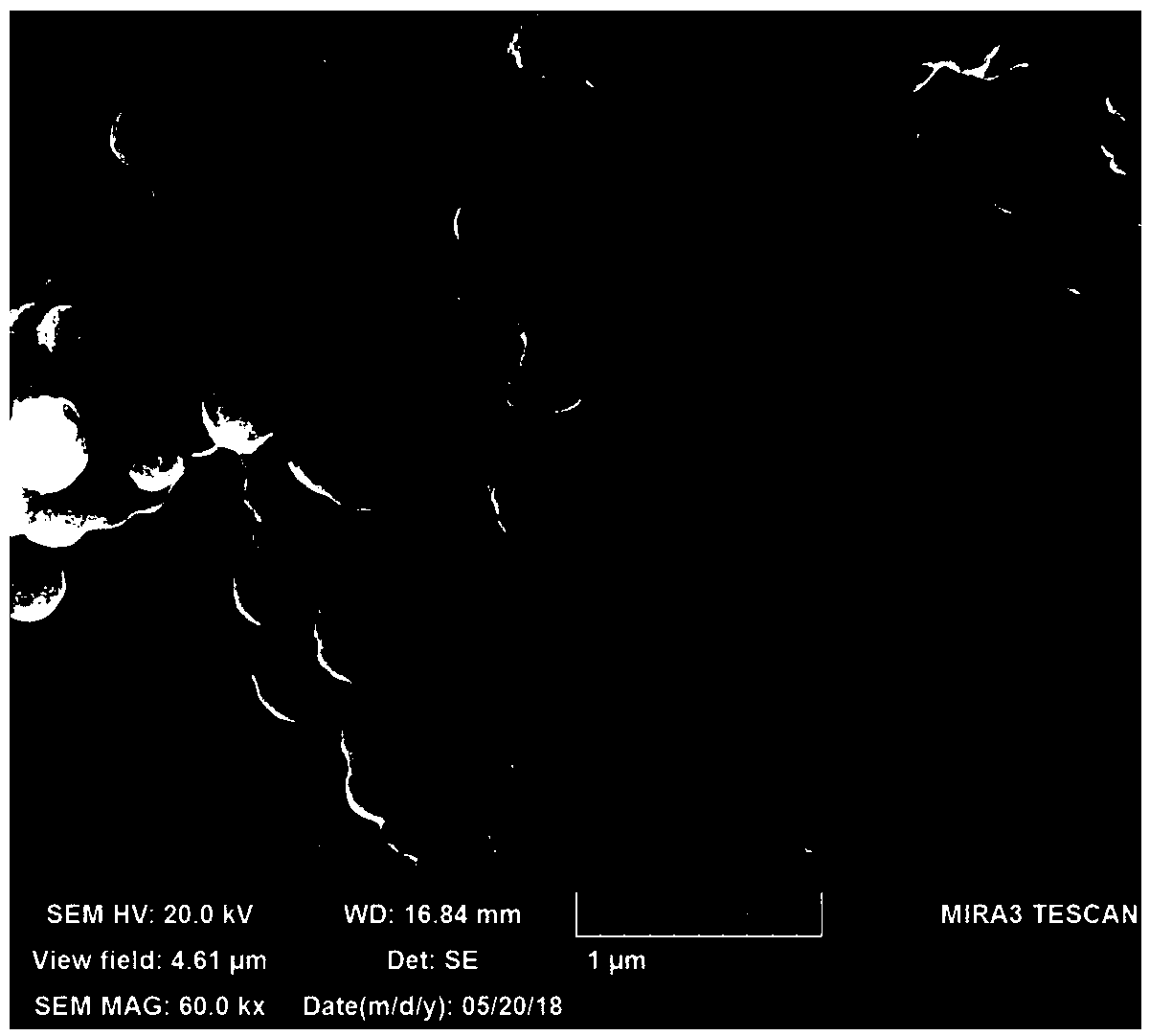

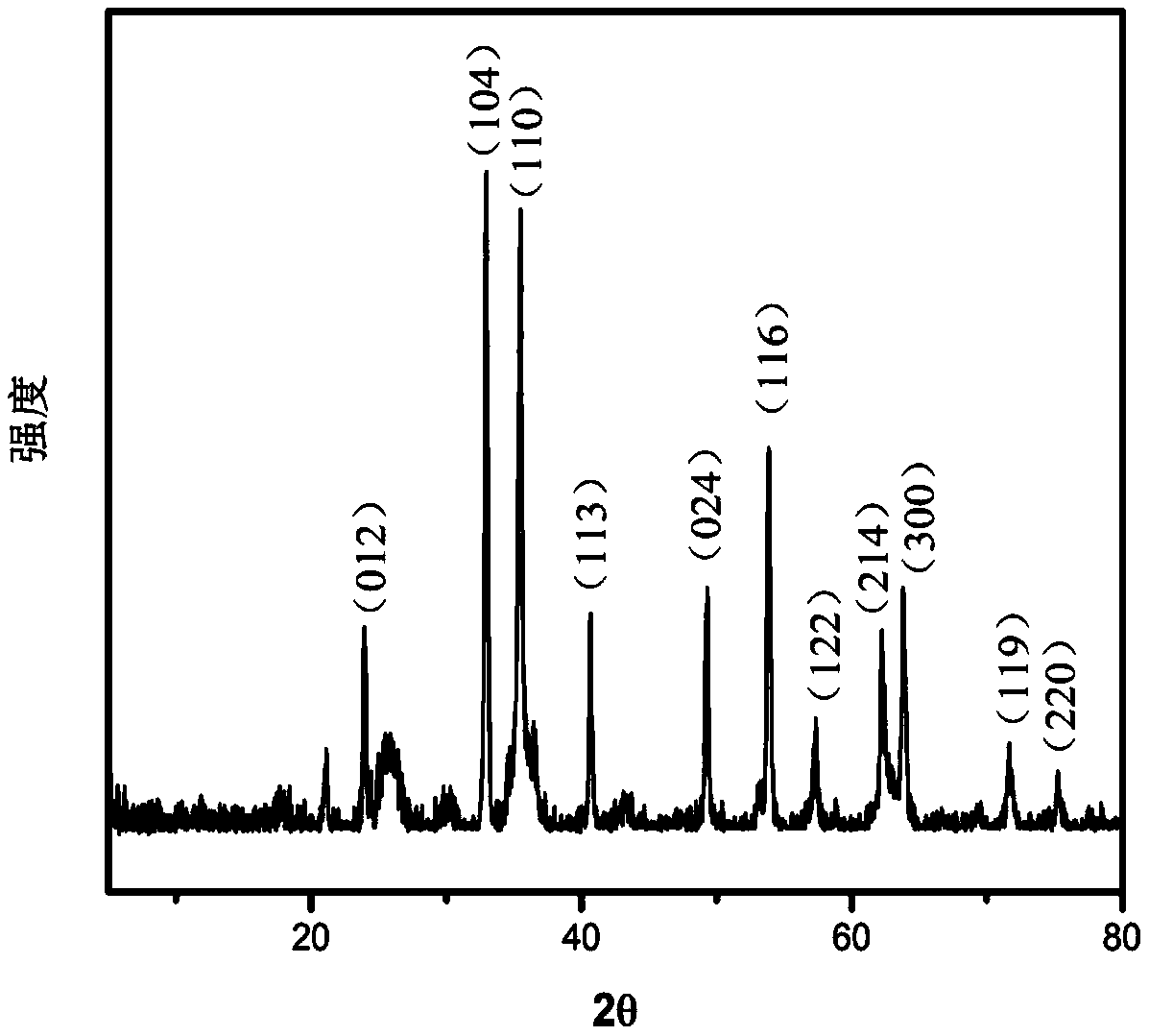

[0030] Step 1: Add 1g of black nickel powder into 20ml of triethylene glycol solvent, and dropwise add 1ml of 1mol / L sodium hydroxide solution, pour it into a polyphenylene (PPL) lined stainless steel reaction kettle, put Put it into an oven, raise the temperature to 250°C, and react for 12 hours. After the reaction, it was naturally cooled to room temperature, and the product was washed several times with deionized water and absolute ethanol, and dried in vacuum to obtain a black powder. Then put the black powder into a ceramic ark, put it into a tube furnace, pass in an inert gas, and under the protection of an inert atmosphere, raise the temperature to 500°C at 5°C / min, keep it warm for 1h, and cool down to room temperature naturally. Finally, use dilute hydrochloric acid to dissolve the nickel nanoparticle core, wash with deionized water several times until PH = 7, and then freeze-dry to obtain a three-dimensional graphene sponge. Take a small amount of three-dimensional g...

Embodiment 2

[0035] Step 1: Add 2g of black nickel powder into 40ml of triethylene glycol solvent, and dropwise add 2ml of 1mol / L sodium hydroxide solution, pour it into a polyphenylene (PPL) lined stainless steel reaction kettle, put Put it into an oven, raise the temperature to 250°C, and react for 12 hours. After the reaction, it was naturally cooled to room temperature, and the product was washed several times with deionized water and absolute ethanol, and dried in vacuum to obtain a black powder. Then put the black powder into a ceramic ark, put it into a tube furnace, pass in an inert gas, and under the protection of an inert atmosphere, raise the temperature to 500°C at 8°C / min, keep it warm for 1h, and cool down to room temperature naturally. Finally, dilute hydrochloric acid was used to dissolve the nickel nanoparticle core, washed several times with deionized water until PH = 7, and then freeze-dried to obtain a three-dimensional graphene sponge. Take a small amount of three-dime...

Embodiment 3

[0040] Step 1: Add 3g of black nickel powder into 60ml of triethylene glycol solvent, and dropwise add 3ml of 1mol / L sodium hydroxide solution therein, pour it into a polyphenylene (PPL) lined stainless steel reactor, put Put it into an oven, raise the temperature to 250°C, and react for 12 hours. After the reaction, it was naturally cooled to room temperature, and the product was washed several times with deionized water and absolute ethanol, and dried in vacuum to obtain a black powder. Then put the black powder into a ceramic ark, put it into a tube furnace, pass in an inert gas, and under the protection of an inert atmosphere, raise the temperature to 500°C at 10°C / min, keep it warm for 1h, and cool down to room temperature naturally. Finally, use dilute hydrochloric acid to dissolve the nickel nanoparticle core, wash with deionized water several times until PH = 7, and then freeze-dry to obtain a three-dimensional graphene sponge. Take a small amount of three-dimensional ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com