Nickel base alloy welding wire for high-temperature alloy fusion welding and preparation method and application thereof

A technology of nickel-based alloys and superalloys, applied in welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of unable to meet the requirements of use, unable to be prepared into wire, easy to form cracks, etc., to achieve moderate fluidity, temperature High, low erosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

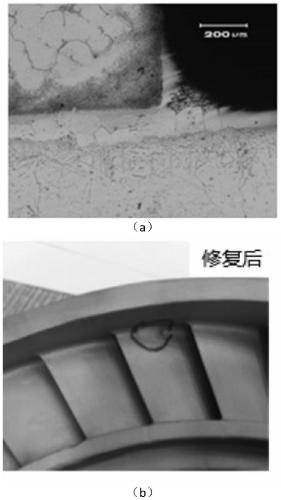

[0029] In this embodiment, the base material to be welded is nickel-based superalloy K4951.

[0030] The chemical composition of the welding wire in this example is (wt.%): C 0.8%, Cr 15.0%, Co 15.5%, Al 8.5%, W5.5%, Mo 4.5%, Nb 4.5%, Y 0.5%, Fe 0.5%, Si 0.5%, the rest is Ni, the master alloy ingot is smelted in a vacuum melting furnace, and the master alloy ingot is smelted in a vacuum induction furnace. Master alloy ingots were produced.

[0031] Welding wire preparation method: Melt the master alloy ingot in a directional solidification furnace at a melting temperature of 1400°C, pour the melted master alloy liquid into an alumina ceramic shell with a cavity diameter of 2.1mm through the liquid outlet, and fill it with Pull out the ceramic shell at a pulling speed of 1 mm / min for directional solidification; break the solidified and cooled ceramic shell, take out the welding wire, and remove the scale on the welding wire on a centerless grinder to obtain the welding wire ma...

Embodiment 2

[0034] In this embodiment, the base material to be welded is nickel-based superalloy K4951.

[0035] The chemical composition of the welding wire in this example is (wt.%): C 0.5%, Cr 5.0%, Co 1.5%, Al 2.5%, W2.5%, Mo 1.5%, Nb 1.8%, Y 0.5%, Fe 0.5%, Si 0.3%, the rest is Ni, the master alloy ingot is smelted by vacuum melting furnace, and the master alloy ingot is smelted by vacuum induction furnace. , to obtain a master alloy ingot.

[0036] Welding wire preparation method: Melt the master alloy ingot in a directional solidification furnace at a melting temperature of 1600°C, pour the melted master alloy liquid into an alumina ceramic shell with a cavity diameter of 1.1 mm through the liquid outlet, and fill it with Pull out the ceramic shell at a pulling speed of 1mm / min for directional solidification; break the solidified and cooled ceramic shell, take out the welding wire, and remove the scale on the welding wire on a centerless grinder to obtain the welding wire material ...

Embodiment 3

[0039] In this embodiment, the base material to be welded is nickel-based superalloy K4951.

[0040]The chemical composition of the welding wire in this example is (wt.%): C 0.3%, Cr 10.0%, Co 2.5%, Al 4.5%, W7.5%, Mo 8.5%, Nb 7.5%, Y 0.5%, Fe 0.3%, Si0.5%, the rest is Ni, the master alloy ingot is smelted by vacuum melting furnace, and the master alloy ingot is smelted by vacuum induction furnace. , to obtain a master alloy ingot.

[0041] Welding wire preparation method: Melt the master alloy ingot in a directional solidification furnace at a melting temperature of 1500°C, pour the melted master alloy liquid into an alumina ceramic shell with a cavity diameter of 1.9 mm through the liquid outlet, and fill it with Pull out the ceramic shell at a pulling speed of 1mm / min for directional solidification; break the solidified and cooled ceramic shell, take out the welding wire, remove the scale on the welding wire on a centerless grinder, and obtain the welding wire with a diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com