A kind of brazing connection technology of zirconium alloy and stainless steel for nuclear reactor

A nuclear reactor and zirconium alloy technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as low toughness, increased corrosion, and greater harm to human body, and achieve high toughness and good corrosion resistance in high temperature water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

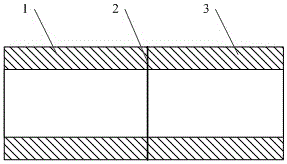

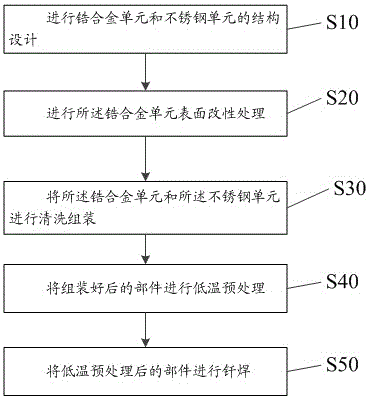

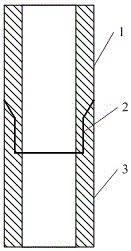

[0041] In Embodiment 1, a brazing connection process between zirconium alloy and stainless steel for nuclear reactor is provided, please refer to Figure 1-Figure 5 , the process includes:

[0042] S10, carry out structural design of zirconium alloy unit and stainless steel unit;

[0043] S20, performing surface modification treatment on the zirconium alloy unit;

[0044] S30, cleaning and assembling the zirconium alloy unit and the stainless steel unit;

[0045] S40, performing low-temperature pretreatment on the assembled components;

[0046] S50, brazing the components after the low-temperature pretreatment.

[0047] Wherein, in the embodiment of the present application, the process steps also include after brazing:

[0048] Conduct performance testing of the brazed components;

[0049] The components after performance testing are processed into finished products.

[0050] Wherein, in the embodiment of the present application, the base material for brazing is zirconiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com