Coal water slurry additive and application thereof

A technology of coal water slurry and additives, applied in the field of coal chemical industry, to achieve the effects of enhancing electrostatic repulsion, improving hydrophilicity, and reducing water separation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Coal sample origin: Yanzhou Coalfield Xinglong Mine. Relevant indicators: ash content (9%); sulfur content (0.48); calorific value (6557 kcal / kg); total moisture content is 5.9%; grindability index HGI is 60.

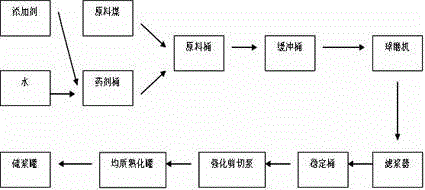

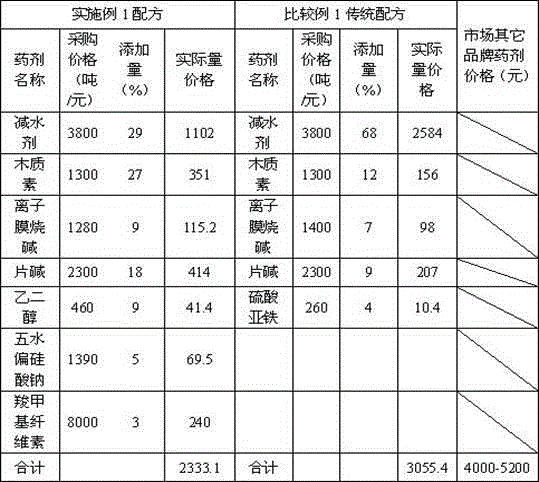

[0031] according to figure 1 The process flow shown produces 290 tons of coal-water slurry; including 199 tons of raw coal, 1.015 tons of additives, and 90 tons of water. The composition of the additives is shown in Table 1. The properties of the prepared coal water slurry are shown in Table 2. The percentage values are all percentage values by weight.

Embodiment 2-3

[0033] Repeat the steps of Example 1, except that the composition of the additives is different, as shown in Table 1. The properties of the prepared coal water slurry are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com