Preparation method of karst foundation grouting single-control cement grout

A preparation method and cement slurry technology, which are applied in soil protection, infrastructure engineering, construction and other directions, can solve the problems of affecting the water environment, low stone rate, slurry loss, etc., and achieve the effect of improving construction efficiency and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in combination with specific embodiments.

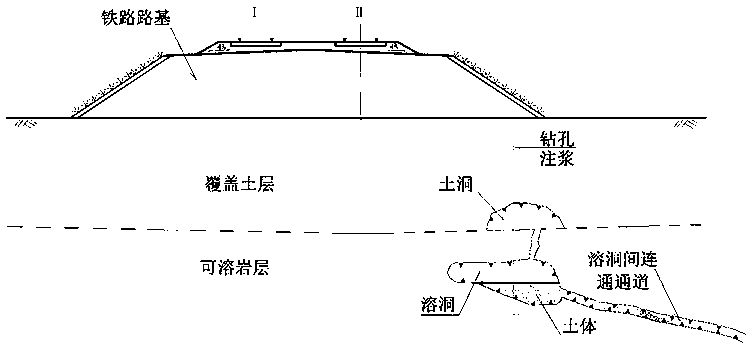

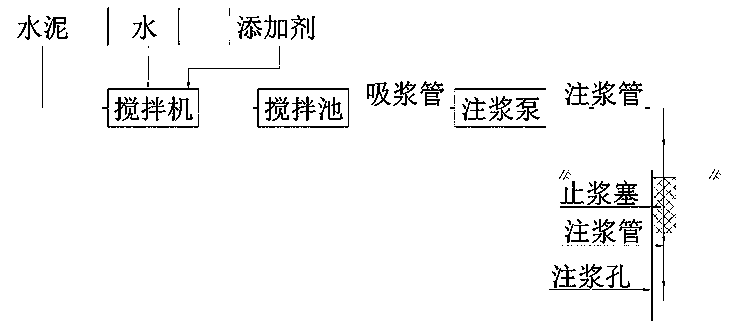

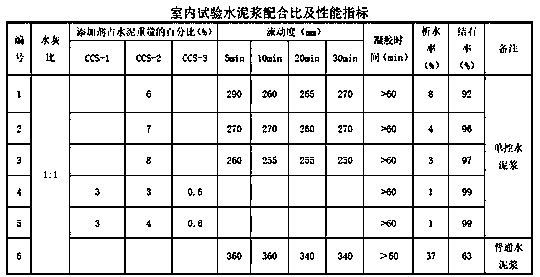

[0022] The invention relates to a method for preparing single-control grout for karst foundation grouting, which is made by stirring cement, additives and water in an iron bucket, and can be constructed by using the technological process of ordinary grout, and is suitable for grouting treatment The karst foundation has poor connectivity and is not easy to lose a large amount of grout. Among them, the cement is selected from Portland cement and ordinary Portland cement, and the water-cement ratio is 1:1.

[0023] The additives include coagulant, water retaining agent and water reducing agent. The coagulation accelerator is selected from various materials such as aluminate, carbonate, quicklime, anhydrous gypsum, metaaluminate, etc., preferably industrial grade sodium carbonate, which has the effect of accelerating the gelation of cement slurry and reducing the water separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com