Uncemented geopolymer grouting material and preparation method thereof

A technology of grouting materials and geopolymers, applied in cement production, etc., can solve the problems of poor working performance, high production energy consumption, high price, etc., and achieve the effects of reducing the porosity of the system, increasing the utilization rate, and high stone formation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

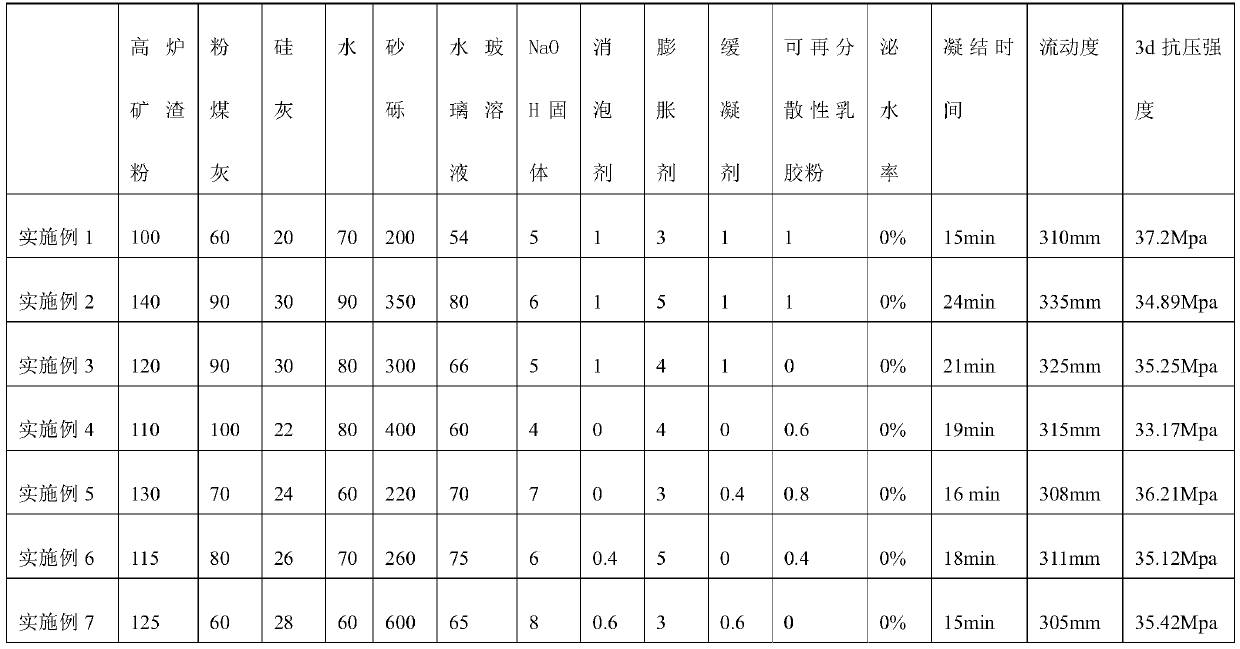

Examples

preparation example Construction

[0034] A kind of preparation method of cementless geopolymer grouting material of the present invention, comprises following concrete steps:

[0035] Step 1), by mass fraction, weigh 100-140 parts of blast furnace slag powder, 60-100 parts of fly ash, 20-40 parts of silica fume, 60-90 parts of water, 200-400 parts of gravel, 54 parts of water glass solution -80 parts, 4-8 parts of NaOH solid, 0-1 part of defoamer, 3-5 parts of expansion agent, 0-1 part of retarder, 0-1 part of redispersible latex powder;

[0036] Preparation of B solution: Mix and stir the weighed water glass solution and NaOH solid until the NaOH solid is completely dissolved to obtain the B solution. Specifically, pour the NaOH solid into the water glass solution and stir slowly until it is completely dissolved, because the NaOH solid is soluble in water The glass solution will release heat, so it needs to be stirred slowly when stirring;

[0037] Step 2), prepare A mixture: mix the weighed blast furnace sl...

Embodiment 1

[0043] Step 1), take raw material by mass fraction:

[0044] 100 parts of blast furnace slag powder, 60 parts of fly ash, 20 parts of silica fume, 70 parts of water, 200 parts of gravel, 48 parts of water glass solution, 5 parts of NaOH solid, 1 part of defoamer, 3 parts of expansion agent, retarder 1 part, 1 part of redispersible latex powder;

[0045] Step 2), mix the weighed NaOH solid in the water glass solution, stir until the NaOH solid is completely dissolved, and obtain the B solution;

[0046] Step 3), put blast furnace slag powder, fly ash and silica fume into mixer and carry out dry mixing and mix evenly, make blast furnace slag powder, fly ash and silica fume fully mix, increase blast furnace slag powder, fly ash and The surface contact area between silica fumes, then put in defoamer, expansion agent, retarder, redispersible latex powder and water in sequence, first stir at 100r / min for 5min, then stir at 300r / min for 5min, get A mixture;

[0047] Step 4), pour ...

Embodiment 2

[0050] Step 1), take raw material by mass fraction:

[0051] 140 parts of blast furnace slag powder, 90 parts of fly ash, 30 parts of silica fume, 90 parts of water, 350 parts of gravel, 80 parts of water glass solution, 6 parts of NaOH solid, 1 part of defoamer, 5 parts of expansion agent, retarder 1 part, 1 part of redispersible latex powder;

[0052] Step 2), mix the weighed NaOH solid in the water glass solution, stir until the NaOH solid is completely dissolved, and obtain the B solution;

[0053] Step 3), put blast furnace slag powder, fly ash and silica fume into mixer and carry out dry mixing and mix evenly, make blast furnace slag powder, fly ash and silica fume fully mix, increase blast furnace slag powder, fly ash and The surface contact area between silica fume, then put in defoamer, expansion agent, retarder, redispersible latex powder and water in turn, first stir at 50r / min for 8min, then stir at 200r / min for 7min, get A mixture;

[0054] Step 4), pour the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com