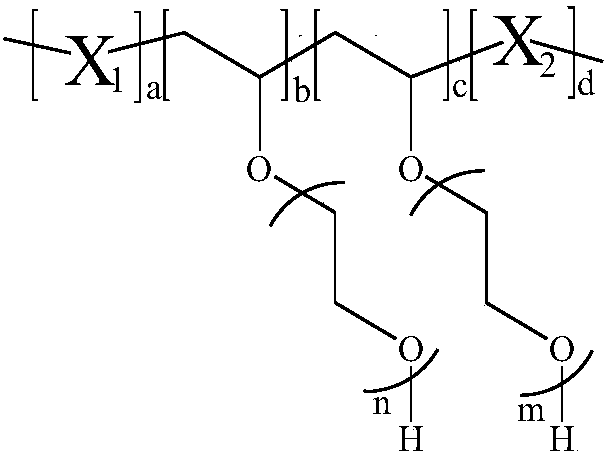

Dispersing agent containing composite long-short side chain polycarboxylate and RAFT (Reversible Addition-Fragmentation chain Transfer) synthesis method of aqueous solution thereof

A technology of chain polycarboxylate and synthesis method, applied in liquid carbon-containing fuel, petroleum industry, fuel and other directions, can solve the problems of unstable dispersion effect of dispersant, high water separation rate, unclear structure, etc., and achieve dispersibility. And the effect of good stability, good dispersion performance and clear structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

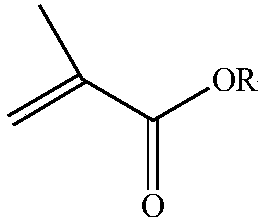

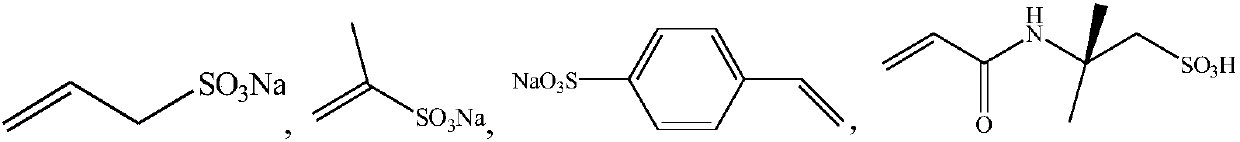

Method used

Image

Examples

Embodiment 1

[0040] 1) First synthesize RAFT (reversible addition-fragmentation chain transfer) reagent BDATT (S-S'-bis(a,a'-dimethyl-a"-acetic acid)-trithiocarbonate): Put 30ml of petroleum Ether was added to a 500mL flask as a solvent, and the CS 2 (6.85g, 0.09mol), chloroform (26.88g, 0.225mol), acetone (13.08g, 0.225mol) and tetrabutylammonium bisulfate (0.6g, 1.775mmol) were mixed into the flask, under nitrogen protection Cool under tap water. In order to keep the temperature below 25°C, a 50% NaOH (50.4 g, 0.63 mol) aqueous solution was added dropwise over 90 minutes, and the reaction was stirred for 12 hours. Then add 225ml of water to dissolve the solid, then add 30ml of concentrated hydrochloric acid to acidify the liquid, stir for 30 minutes under the protection of nitrogen, and adjust the pH to about 7. The solid was obtained by filtration, washed with water, and dried to a constant weight to obtain a khaki product. Finally, it was purified by stirring in a solution of tolue...

Embodiment 2

[0044] 1) First synthesize RAFT (reversible addition-fragmentation chain transfer) reagent BDATT (S-S'-bis(a,a'-dimethyl-a"-acetic acid)-trithiocarbonate): Put 60ml of petroleum Ether was added to a 1000mL flask as a solvent, and the CS 2 (13.79g, 0.18mol), chloroform (53.75g, 0.45mol), acetone (26.15g, 0.45mol) and tetrabutylammonium bisulfate (1.205g, 3.55mmol) were mixed and added to the flask, under nitrogen protection Cool under tap water. In order to keep the temperature below 25°C, 50% NaOH (100.8 g, 1.26 mol) aqueous solution was added dropwise within 90 minutes, and the reaction was stirred for 12 hours. Then add 450ml of water to dissolve the solid, then add 60ml of concentrated hydrochloric acid to acidify the liquid, stir for 30 minutes under nitrogen protection, and adjust the pH to about 7. The solid was obtained by filtration, washed with water, and dried to a constant weight to obtain a khaki product. Finally, it was purified by stirring in a solution of tolue...

Embodiment 3

[0048] 1) First synthesize RAFT (reversible addition-fragmentation chain transfer) reagent BDATT (S-S'-bis(a,a'-dimethyl-a"-acetic acid)-trithiocarbonate): Put 30ml of petroleum Ether was added to a 500mL flask as a solvent, and the CS 2 (6.85g, 0.09mol), chloroform (26.88g, 0.225mol), acetone (13.08g, 0.225mol) and tetrabutylammonium bisulfate (0.6g, 1.775mmol) were mixed into the flask, under nitrogen protection Cool under tap water. In order to keep the temperature below 25° C., a 50% NaoH (50.4 g, 0.63 mol) aqueous solution was added dropwise over 90 minutes, and the reaction was stirred for 12 hours. Then add 225ml of water to dissolve the solid, then add 30ml of concentrated hydrochloric acid to acidify the liquid, stir for 30 minutes under the protection of nitrogen, and adjust the pH to about 7. The solid was obtained by filtration, washed with water, and dried to a constant weight to obtain a khaki product. Finally, it was purified by stirring in a solution of tol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com