Preparation method of acetate starch

A technology of acetate starch and starch, which is applied in the field of preparation of acetate starch, can solve the problems of poor freeze-thaw stability, poor film-forming property and transparency, and easy aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

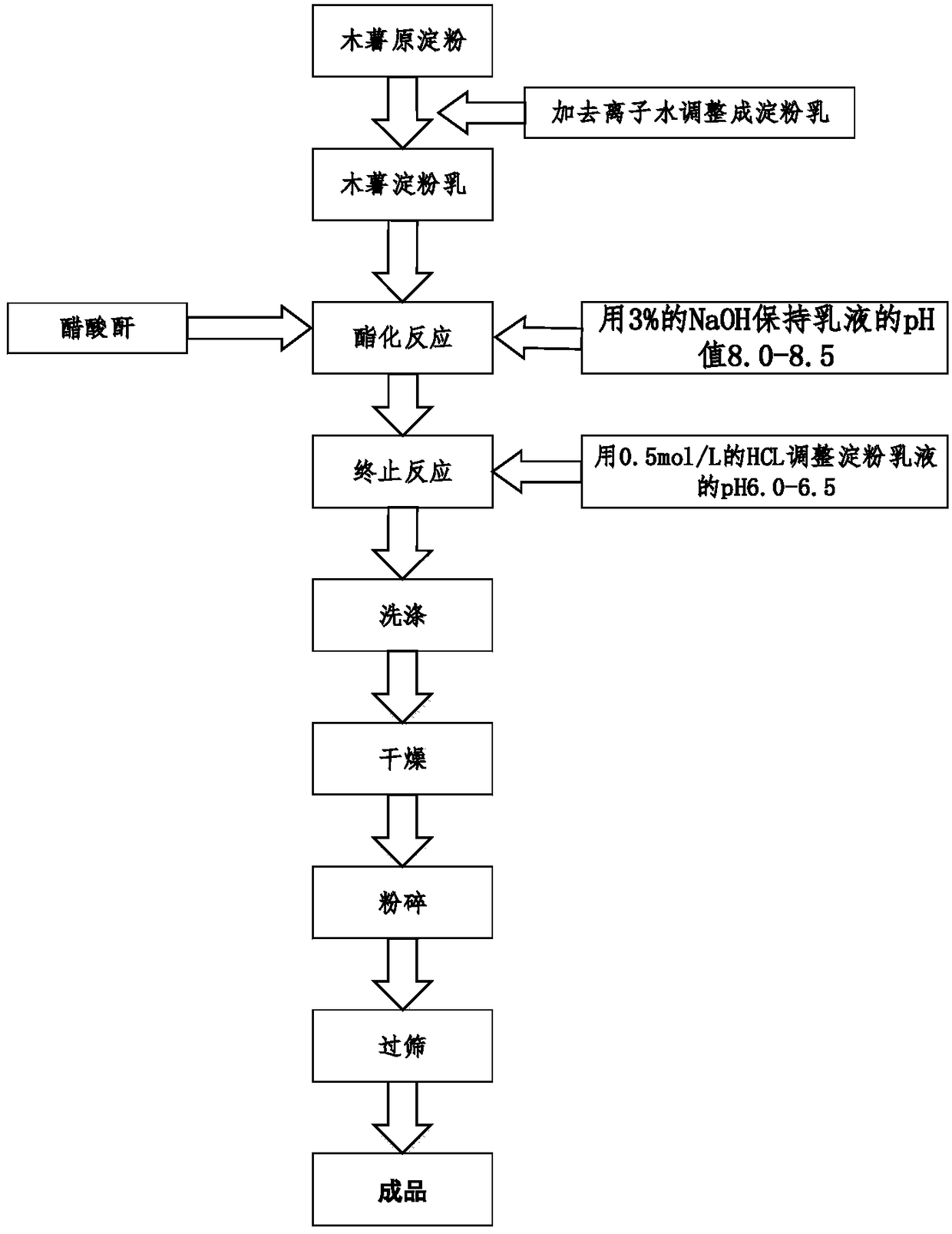

[0031] like figure 1 As shown, the preparation method of starch acetate of the present invention comprises the following steps:

[0032] (1) get tapioca starch and add water to prepare the starch emulsion (w / w density is about 1.18) with a mass concentration of 40wt%, uniformly stir the starch for 10min to fully disperse the starch, obtain a uniform starch emulsion, and carry out with the sodium hydroxide solution of 3wt% Alkalization treatment, adjusting the pH of the emulsion to 8.0-8.5, and then standing for 10min;

[0033] (2) adding acetic anhydride dropwise to the starch emulsion after the alkalization treatment to carry out esterification (the addition amount of the acetic anhydride accounts for 7wt% of the starch emulsion amount), and using an atomizing nozzle to dropwise add 3wt% hydrogen The sodium oxide solution is controlled to stabilize the pH value of the reaction solution at 8.0-8.5, and the reaction temperature is controlled at 25 ° C to carry out the reaction...

Embodiment 2

[0041] like figure 1 As shown, the preparation method of starch acetate of the present invention comprises the following steps:

[0042] (1) get tapioca starch and add water to prepare the starch emulsion (w / w density is about 1.18) with a mass concentration of 40wt%, uniformly stir the starch for 10min to fully disperse the starch, obtain a uniform starch emulsion, and carry out with the sodium hydroxide solution of 3wt% Alkalization treatment, adjusting the pH of the emulsion to 8.0-8.5, and then standing for 10min;

[0043] (2) adding acetic anhydride dropwise to the starch emulsion after the alkalization treatment to carry out esterification (the addition amount of the acetic anhydride accounts for 7wt% of the starch emulsion amount), and using an atomizing nozzle to dropwise add 3wt% hydrogen The sodium oxide solution is controlled to stabilize the pH value of the reaction solution at 8.0-8.5, and the reaction temperature is controlled at 30 ° C to carry out the reaction...

Embodiment 3

[0047] like figure 1 As shown, the preparation method of starch acetate of the present invention comprises the following steps:

[0048] (1) get tapioca starch and add water to prepare the starch emulsion (w / w density is about 1.18) with a mass concentration of 40wt%, uniformly stir the starch for 10min to fully disperse the starch, obtain a uniform starch emulsion, and carry out with the sodium hydroxide solution of 3wt% Alkalization treatment, adjusting the pH of the emulsion to 8.0-8.5, and then standing for 10min;

[0049] (2) adding acetic anhydride dropwise to the starch emulsion after the alkalization treatment to carry out esterification (the addition amount of the acetic anhydride accounts for 7wt% of the starch emulsion amount), and using an atomizing nozzle to dropwise add 3wt% hydrogen The sodium oxide solution is controlled to stabilize the pH value of the reaction solution at 8.0-8.5, and the reaction temperature is controlled at 35 ° C to carry out the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com