Method for preparing high-concentration water-coal-slurry through coal with high oxygen content

A high-concentration water and oxygen content technology, applied in the direction of liquid carbon-containing fuel, petroleum industry, fuel, etc., can solve the problem that the high-concentration coal-water slurry technology has not made breakthrough progress, and achieve good fluidity and stability, The effect of reducing pulping cost and using less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

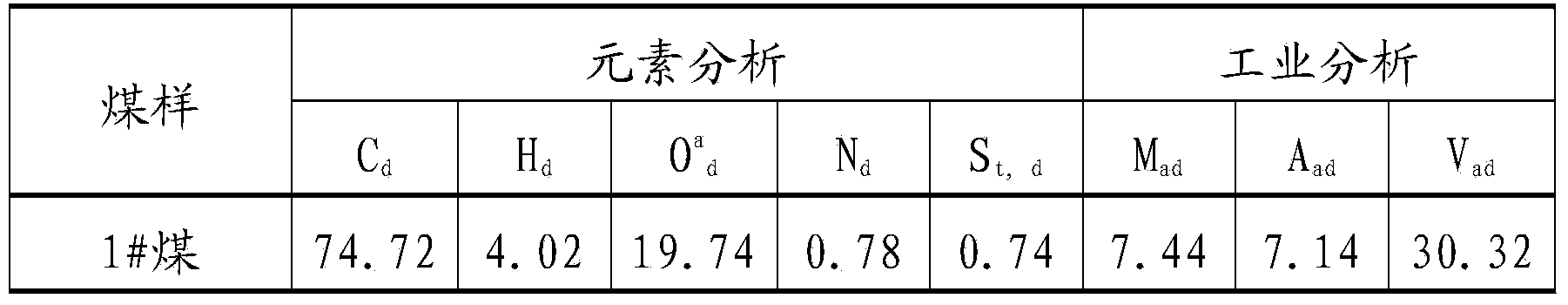

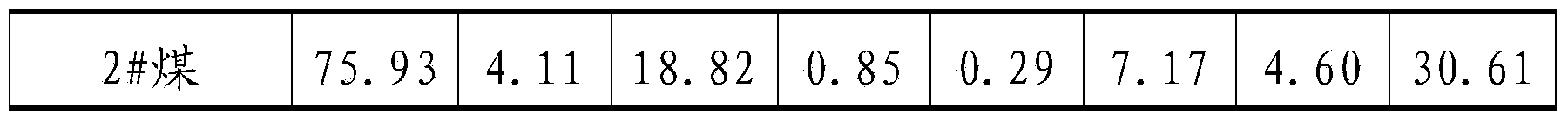

[0025] The amount of coal sample is about 3kg, pre-crushed to less than 10mm, and then finely crushed to less than 3mm with a roller crusher, and the finely crushed coal sample is evenly spread on the tray, and placed in a constant temperature blast drying oven at 105°C-110°C The drying time is 10-14 hours, and the moisture content of the dried high-oxygen coal is not more than 2%. The dried coal sample is prepared by grinding coal with a ball mill. The diameter ratio of the steel balls is 20mm, 12mm and 5mm, and the mass ratio is 20%:50%:30%. The speed of the ball mill is set at 150-200r / min. Coal grinding time 5-10min. Coal samples are screened with 40-mesh and 200-mesh sieves, and the coal with a particle size of 40 mesh to 200 mesh (coarse) and less than 200 mesh (fine) is classified according to the mass ratio of (4-6): (6-4) Then add water and additives (ZM-19 high-efficiency coal-water slurry additive, the dosage is 0.3% of the dry basis coal, wt) and mix evenly, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com