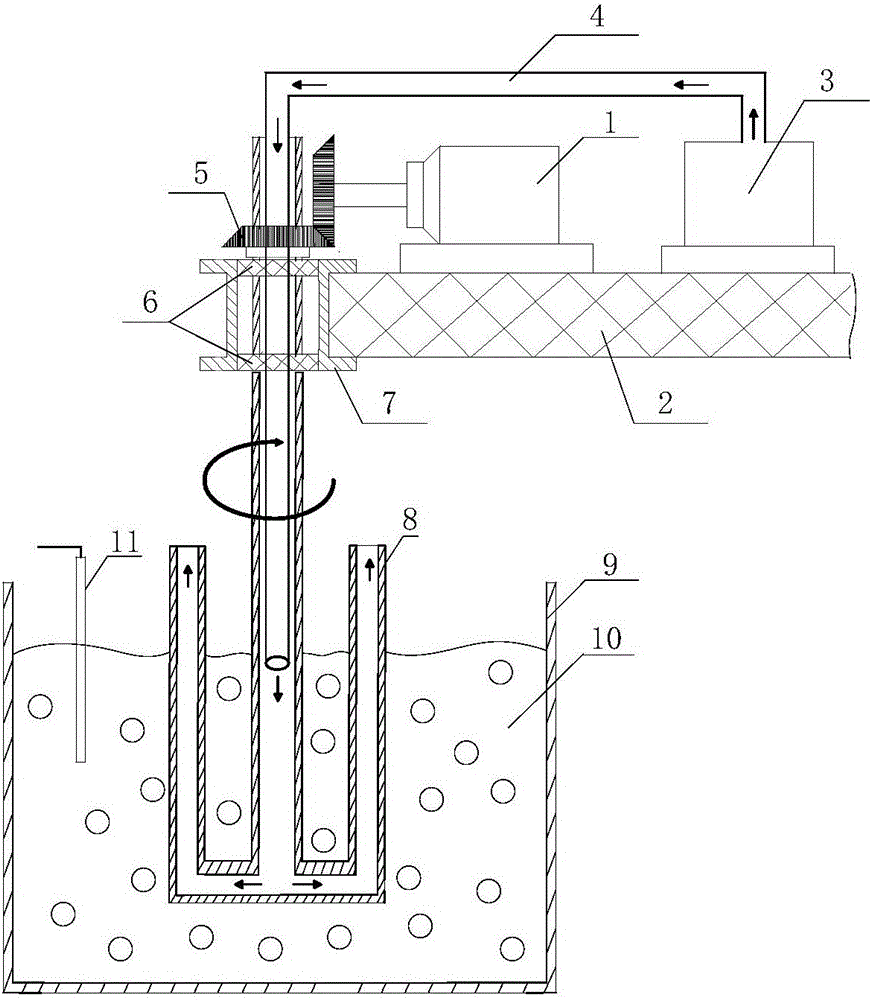

Device and method for preparing light alloy semi-solid slurry through air-cooling multi-tube stirring

A semi-solid slurry and light alloy technology, which is applied in the field of air-cooled multi-tube stirring device for preparing light alloy semi-solid slurry, can solve the difficulties of large-volume semi-solid slurry preparation and industrialization, poor reliability of continuous work, cleaning Maintenance is cumbersome and other problems, to achieve the effect of easy industrial promotion and application, wide range of applicable alloys, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

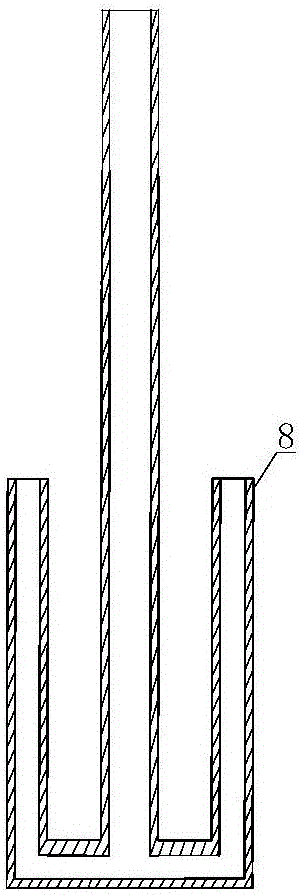

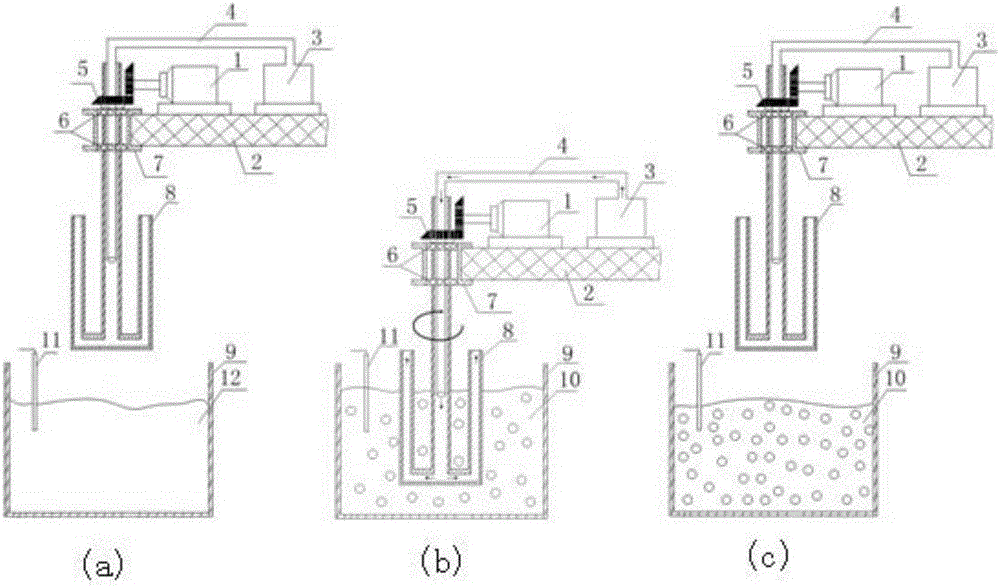

Method used

Image

Examples

Embodiment 1

[0060] Example 1: Comparison of A380 aluminum alloy semi-solid slurry prepared by ordinary stirring mechanism, air-cooled single-tube stirring mechanism and air-cooling multi-tube stirring mechanism, the steps are as follows:

[0061] (1-1) The liquidus and solidus temperatures of the A380 die-casting aluminum alloy used in the test are 585°C and 504°C, respectively. The aluminum alloy ingot is placed in a crucible resistance furnace with a preheating temperature of 250°C. Refining after the liquid temperature rises to 690°C, press the dried hexachloroethane into the bottom of the aluminum alloy liquid with a bell jar, the amount added is 0.5% of the total weight of the aluminum alloy liquid, shake gently to degas the melt , slag removal and refining treatment, and finally cool down the aluminum alloy melt to 610°C and keep it warm.

[0062] (1-2) The stirring speed of the multi-tube stirring rod in the preparation device is 400r / min, the air intake in the air duct is 300L / min...

Embodiment 2

[0065] Embodiment 2: Preparation of A356 cast aluminum alloy semi-solid slurry, the steps are as follows:

[0066](2-1) The liquidus and solidus temperatures of the A356 cast aluminum alloy used in the test are 615°C and 556°C, respectively. Put the aluminum alloy ingot into a crucible resistance furnace with a preheating temperature of 300°C, Refining after the liquid temperature rises to 700°C, press the dried hexachloroethane into the bottom of the aluminum alloy liquid with a bell jar, the amount added is 0.5% of the total weight of the aluminum alloy liquid, shake gently to degas the melt , slag removal and refining treatment, and finally cool the aluminum alloy melt to 650°C and keep it warm.

[0067] (2-2) The stirring speed of the multi-tube stirring rod in the preparation device is 400r / min, the air intake in the air duct is 400L / min, the inner diameter of the air duct is 10mm, there are 3 stirring tubes, the wall thickness of the stirring tube is 5mm, and the inner d...

Embodiment 3

[0068] Embodiment 3: Preparation of 7075 deformed aluminum alloy semi-solid slurry, the steps are as follows:

[0069] (3-1) The liquidus and solidus temperatures of the 7075 deformed aluminum alloy used in the test are 635°C and 477°C, respectively. Put the aluminum alloy ingot into a crucible resistance furnace with a preheating temperature of 300°C, Refining after the liquid temperature rises to 720°C, press the dried hexachloroethane into the bottom of the aluminum alloy liquid with a bell jar, the amount added is 0.5% of the total weight of the aluminum alloy liquid, shake gently to degas the melt , slag removal and refining treatment, and finally cool the alloy melt to 660°C and keep it warm.

[0070] (3-2) The stirring speed of the multi-tube stirring rod in the preparation device is 300r / min, the air intake in the air duct is 300L / min, the inner diameter of the air duct is 10mm, there are 3 stirring tubes, the wall thickness of the stirring tube is 5mm, and the inner d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com