Biocatalytic clean pulping agent and application process thereof

A technology of clean pulping and catalysis, applied in the regeneration of pulping liquid, pulping of cellulose raw materials, pulp bleaching, etc., can solve the problems of environmental pollution, achieve good safety, reduce pulping costs, and benefit fully The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

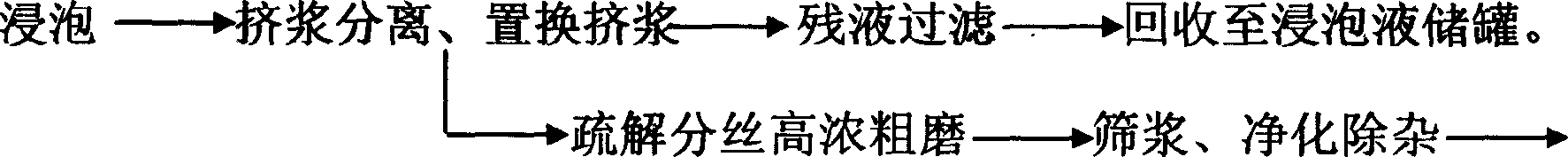

Method used

Image

Examples

Embodiment 1

[0065] Preparation of Biocatalytic Cleaning Pulping Agent Soaked Wheat Straw

[0066] Location: Yinchuan, Ningxia, with a dosage of 9 tons

[0067] Preparation formula is as follows: (weight percentage)

[0068] Amylase 3‰

[0069] Laccase 2‰

[0070] Hydroxybenzotriazole 5‰

[0072] SL-1 paper cooking aid 5‰

[0073] Sodium dodecyl sulfonate 5‰

[0075] the rest is water

[0076] Soaking temperature 50-60℃

[0077] soaking time

[0078] The first 5.5 hours hardness 11.2 (potassium permanganate value)

[0079] The second 5 hours hardness 12.2

[0080] The third time 5+10 hours 30 ℃ hardness 13.7

[0081] The fourth 5.5 hours 40 ℃ hardness 15.3

[0082] The bleaching rate of bleaching pulp is 6.5%, the soaking liquid ratio is 8%, and the papermaking is 18g / m 2 Toilet paper, soaked black liquor is continuously reused without discharge, and other processes are the same as the alkaline papermaking and pulping ...

Embodiment 2

[0085] Prepare 9 tons of soaked wheat straw of this biocatalytic cleaning pulping agent.

[0086] Location: Alkali production line of Kangda Paper Industry, Weixian County, Hebei Province

[0087] Catalyst preparation ratio:

[0088] Amylase 2‰

[0089] Laccase 1‰

[0090] Hydroxybenzotriazole 4‰

[0092] SL-1 paper cooking aid 1%

[0094] aqueous solution

[0095] Soaking temperature 50-60℃

[0096] Soaking process time: 4.5-6.5 hours

[0097] Immersion implemented at 1.2m 3 in a hydropulper

[0098] Liquid ratio 12%-14%

[0099] The continuous immersion cycle is reused 32 times, and the black liquor is reused by filtration every time without any discharge. The pulp bleaching rate is 6.7%, and the yield is estimated to be 46.75% (the yield of the same batch of wheat straw in the soda production line of the factory is 38.3%)

[0100] The pulp hardness before bleaching is 13.2-14 (potassium permanganate value...

Embodiment 3

[0103] The proportioning ratio of the preparation of the biochemical catalysis pulping agent is similar to that of the above formula. The process conditions are similar, soaking, crushing and rubbing cotton stalks. After soaking for 12 hours, the pulp hardness is 13.2, the whiteness of bleached pulp is ≥73°C, the fiber bundles are obviously long and white, and the example is successful.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com