Method for preparing high-concentration coal water slurry by means of fine crushing and little grinding

A technology of high-concentration water and coal slurry, which is applied in the field of preparing high-concentration coal-water slurry and preparing high-concentration coal-water slurry with fine crushing and less grinding, can solve the problem of unreasonable particle size distribution of coal slurry, low gasification efficiency and low effective gas content and other problems, to achieve the effect of saving pulping energy consumption, reducing pulping cost and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1, high concentration coal-water slurry is prepared by finely breaking and less grinding

[0036] The raw coal is Xinjiang Heishan coal (hereinafter referred to as "Heishan coal"), and its total water Mt=20%, Aar=14%, Var=30%.

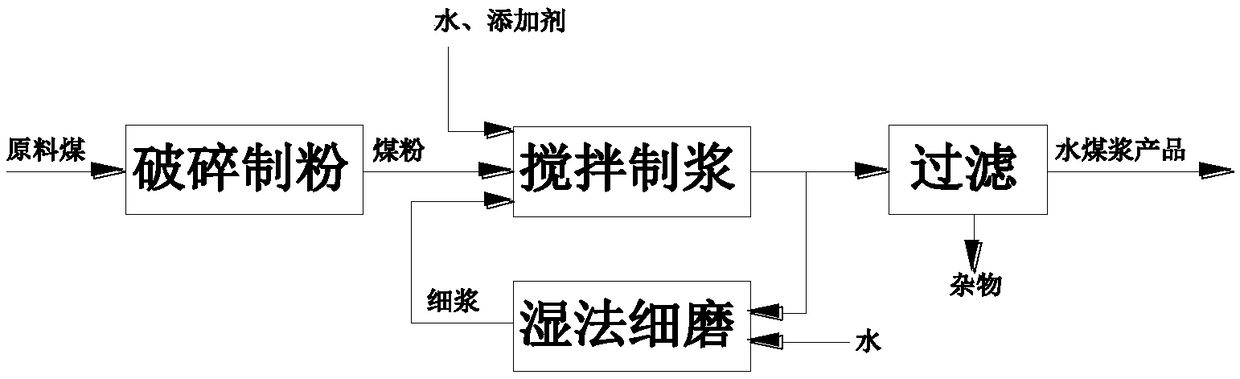

[0037] according to figure 1 In the process of preparing high-concentration coal-water slurry by finely breaking and less grinding in the present invention, the process of using the raw coal to prepare high-concentration coal-water slurry is as follows:

[0038] (1) Finely crushing Heishan coal to prepare coal powder with a particle size≤1.0mm to obtain fine coal powder;

[0039] (2) Add fine coal powder, water and sodium lignin sulfonate into a mixing tank according to the mass ratio of 1:0.9:0.005 on a dry basis, and stir to prepare a slurry with a concentration of 45wt%;

[0040] (3) Send the slurry prepared in step (2) into a wet fine grinder for grinding, and prepare a fine slurry with an average particle diameter of 18 μm, whi...

Embodiment 2

[0045] Embodiment 2, preparation of high-concentration coal-water slurry by fine crushing and less grinding

[0046] The Shenfu coal used is a common long-flame coal in northern Shaanxi, containing 5.9% of analytical water, 12.8% of total water, and 19.9% of ash.

[0047] according to figure 1 In the process of preparing high-concentration coal-water slurry by finely breaking and less grinding in the present invention, the process of using the raw coal to prepare high-concentration coal-water slurry is as follows:

[0048] (1) finely crushing Shenfu coal to prepare pulverized coal with a particle size of ≤0.8mm;

[0049] (2) Add the fine coal powder, water and ammonium lignosulfonate into the mixing tank according to the mass ratio of 1:1:0.005 on a dry basis, and stir to prepare a slurry with a concentration of 45wt%;

[0050] (3) Send the slurry prepared in step (2) into a wet fine grinder for grinding, and prepare a fine slurry with an average particle diameter of 20 μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com