Water oil machine of arc telescopic double-layer mesh screen

A telescopic and mesh screen technology, which is applied in water conservancy projects, general water supply conservation, and cleaning of open water surfaces. It can solve problems such as low efficiency of oil-absorbing felts and marine pollution, achieve good recycling efficiency, prevent marine pollution, and save pollution. The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

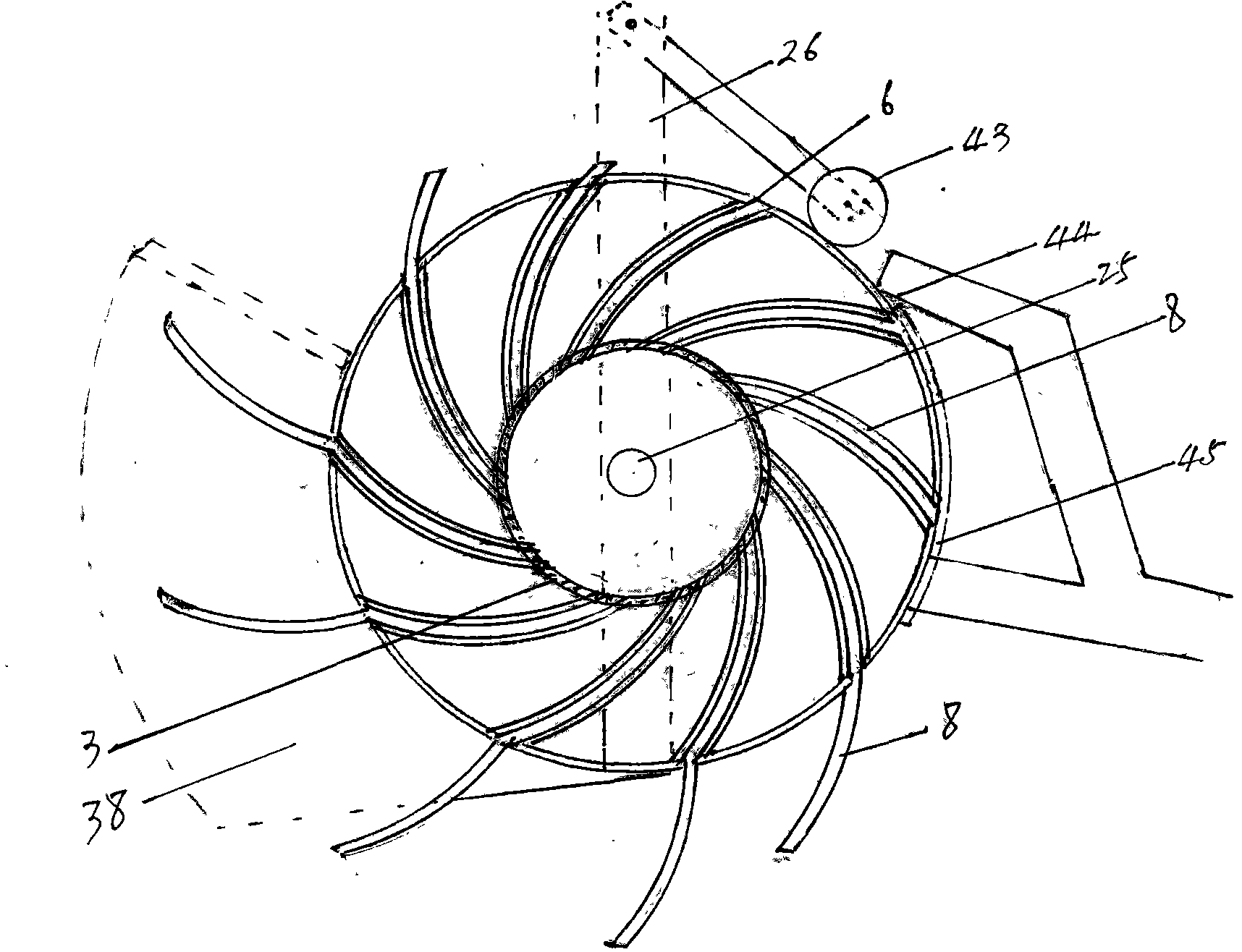

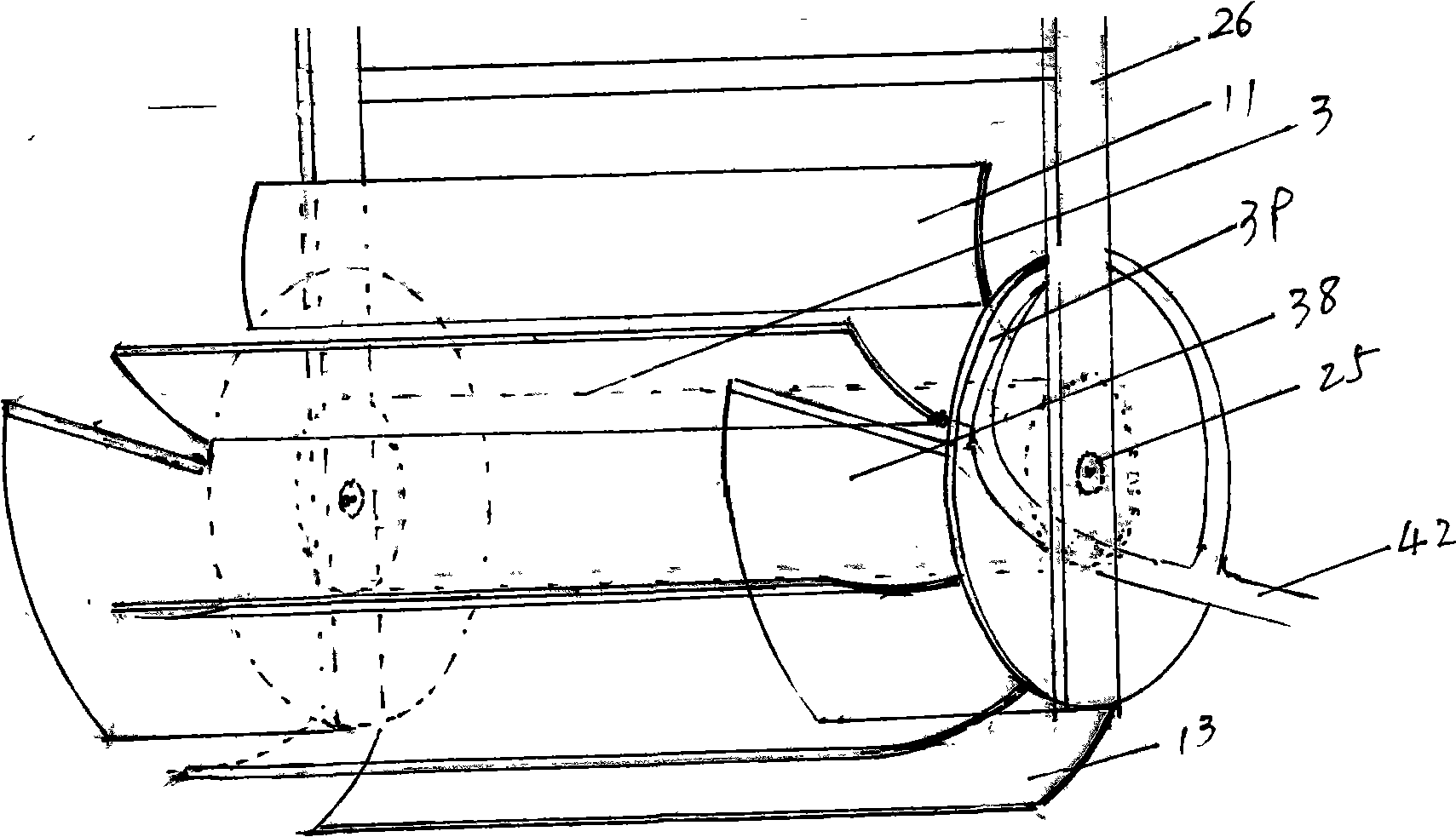

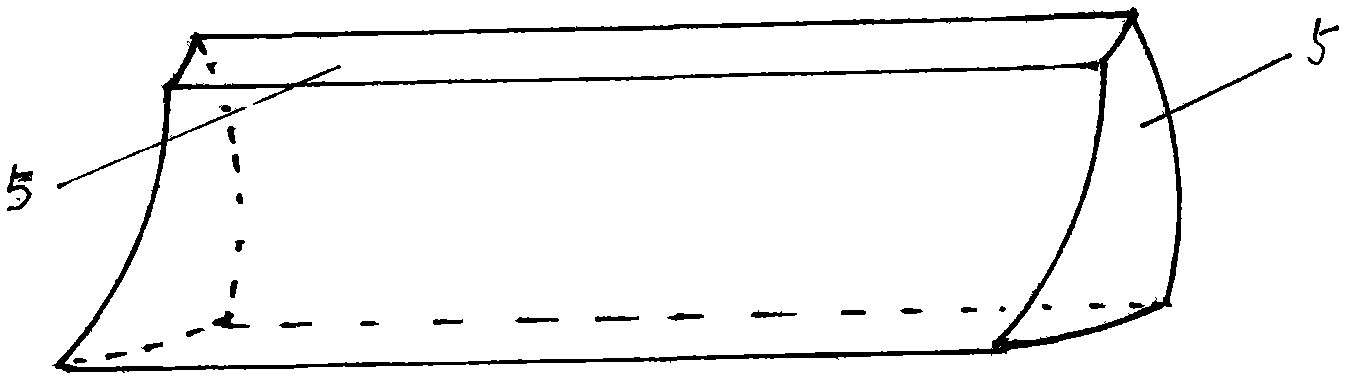

[0024] exist figure 1 , figure 2 Set the oil skimmer as a drum-shaped (1) tube (30) of nearly half the diameter of the end face of the drum (2) to connect the required length with the concentric connection and fixation of the two ends of the drum; figure 1 , Figure 5 Among them, an array of left-right symmetrical arc notch slides (4) are fixed on the inside of the left and right end faces at a certain angle, one end is close to the outside of the barrel, and the other end is flat and coincident with the outer circumference of the barrel end face. figure 1 , image 3 According to the length of the tube, several floating barrels (or foamed plastic floating bodies) whose end faces are in shape and size consistent with the shape of the gap between adjacent slideways are set, and are fixed as a whole between the gaps between the slideways at both ends. ;exist figure 1 , Figure 5 The gap separated by the notch slideway between the middle floating bucket and the floating buck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com