Method and device for cooling high-temperature calcined coke of carbon rotary kiln

The technology of a cooling device and a cooling method, which is applied to the cooling field of high-temperature calcined coke in a carbon rotary kiln, can solve the problems of high cost of cooling water circulation and treatment system, harsh operating environment conditions, oxidation of high-temperature materials, etc. The effect of saving power consumption and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

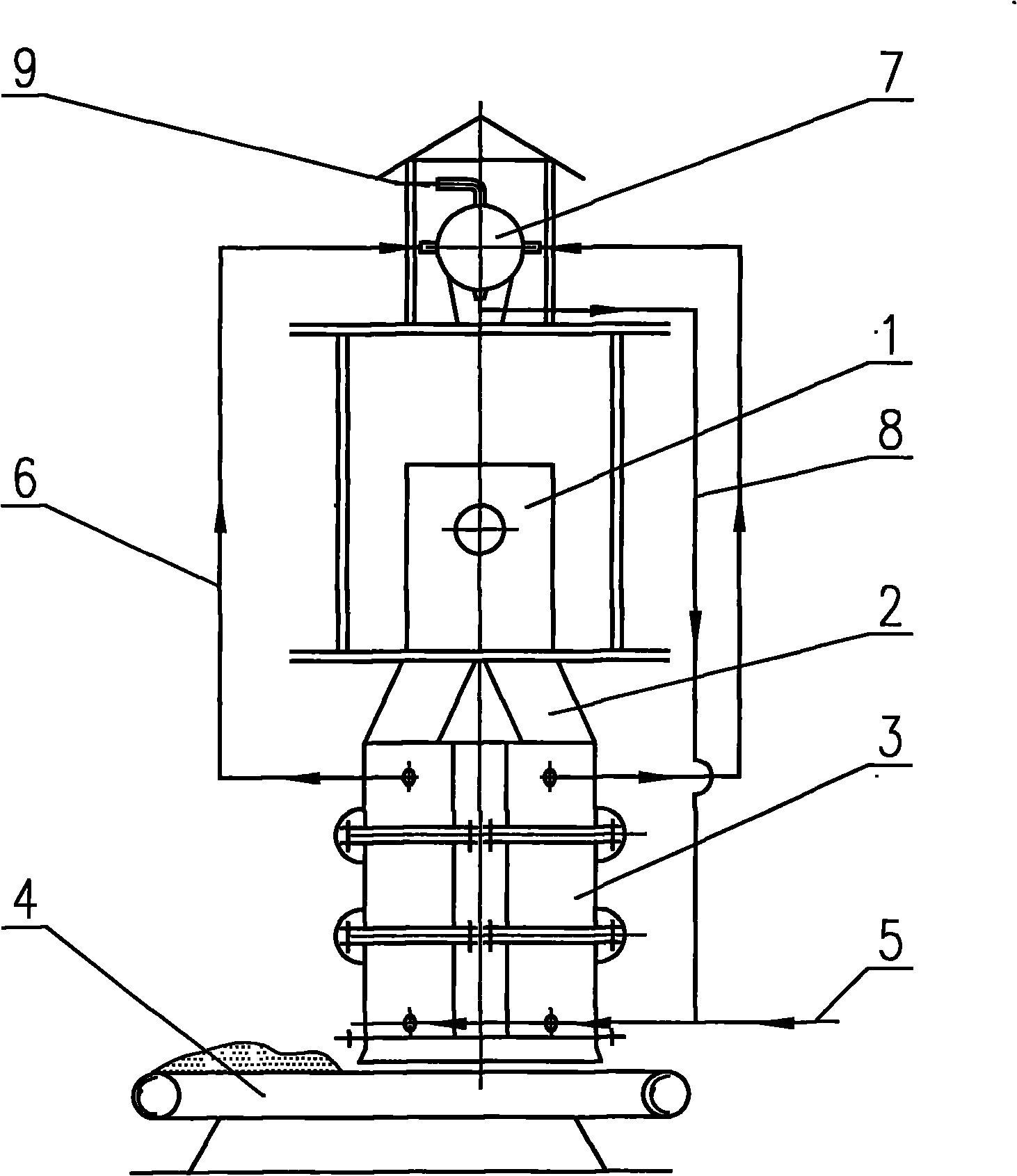

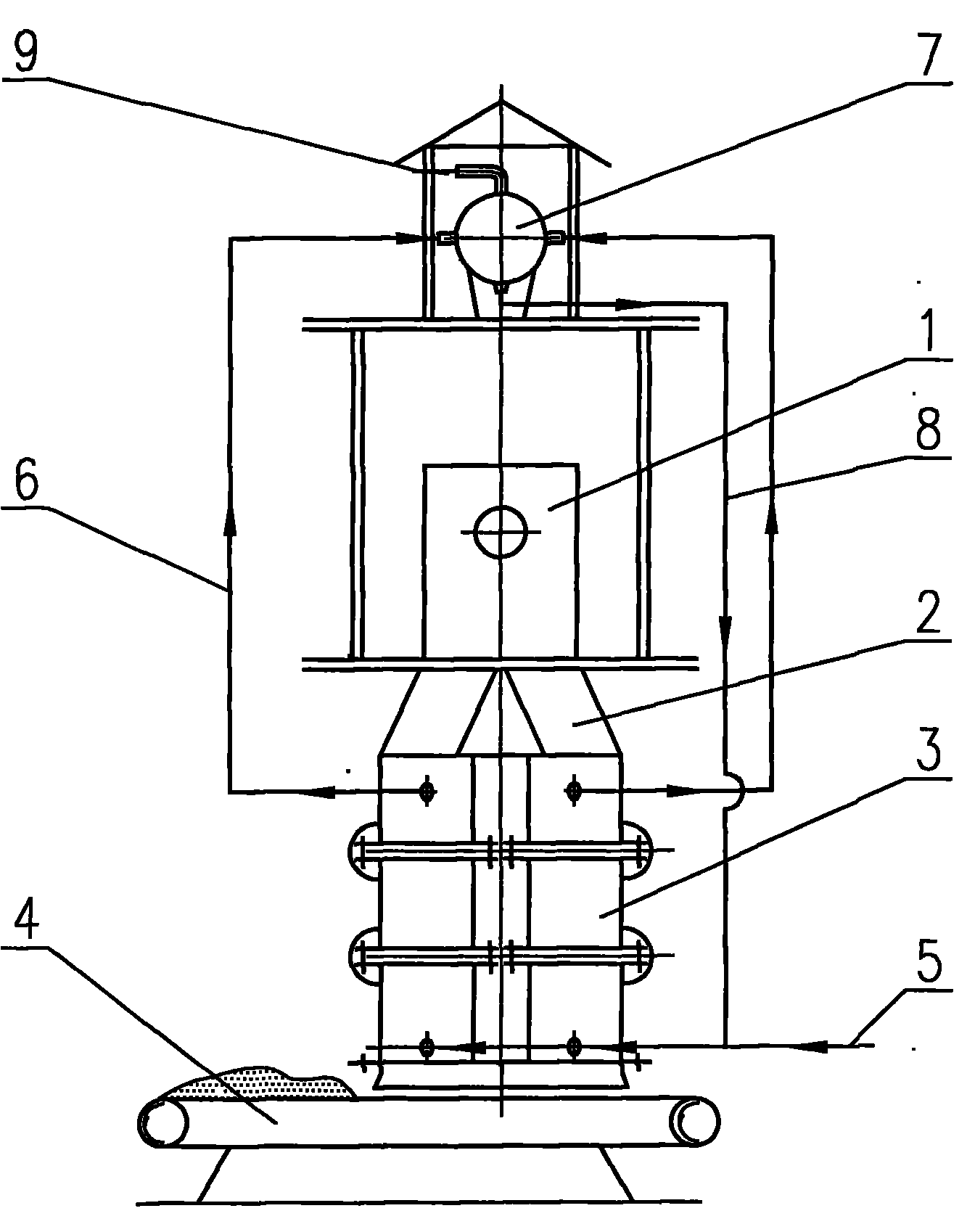

[0031] Such as figure 1 A cooling method for high-temperature calcined coke in a carbon rotary kiln is shown in the present invention, comprising the following steps: the high-temperature calcined coke is introduced into the cooling jacket through the launder at the bottom of the rotary kiln head; the cooling water in the cooling jacket is cooled from the lower part of the cooling jacket The water inlet enters the interlayer cavity, and the steam generated after heat exchange between the high-temperature calcined coke and the cooling water in the cooling jacket enters the gas riser from the steam outlet on the upper part of the cooling jacket, and the steam enters the high-level steam drum from the gas riser , output from the steam output port of the high-level ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com