Marble sewage treatment production line

A sewage treatment and marble technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve the problems of sewage not meeting the use requirements, high construction costs, environmental pollution, etc., to achieve The effect of saving pollution control costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

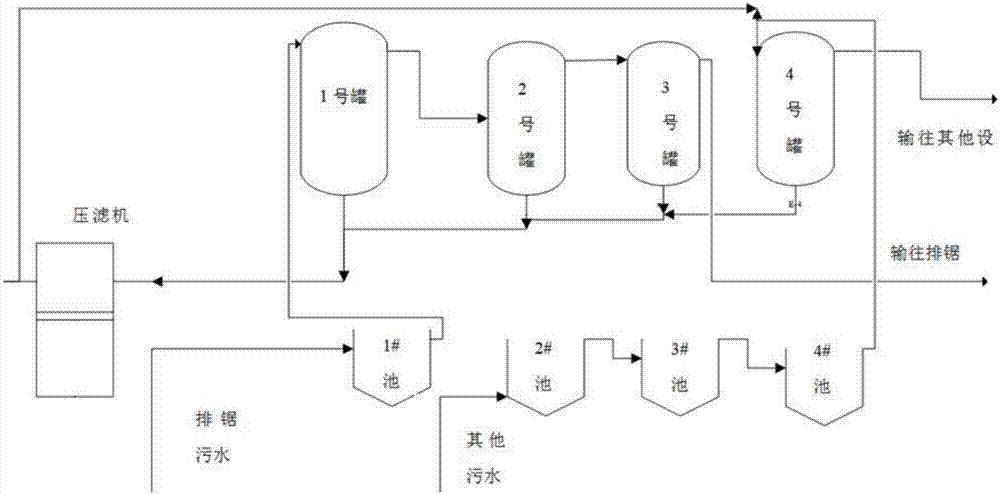

[0017] like figure 1 Shown: The marble sewage treatment production line uses the self-weight of the suspended particles in the sewage. The treatment system follows the principle of mass settlement and adopts a combination of vertical flow sedimentation in the tank and advection sedimentation in the pool to make the suspended particles settle to the bottom of the tank, thereby Realize mud-water stratification and sewage purification. The marble sewage produced by the gang saw workshop and the tooth workshop is treated by vertical flow sedimentation. The sewage from the equipment enters the primary sedimentation tank through the ditch, settles in the sedimentation tank, and is pumped through the 1# tank and 2 tank in turn. After the tanks # and 3# have settled successively, the tank 3# is finally sent to the road tooth workshop and the gang saw workshop for use. Except the gang saw workshop and the gang saw workshop, the sewage generated by all equipment is treated by the sedimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com