Graphene/metal oxide semiconductor (MoS2) nano self-lubricating composite material and preparation method thereof

A composite material, graphene technology, applied in the field of MoS2, to achieve the effect of simple and easy preparation method, high yield and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of graphene oxide nanosheets: Disperse 0.015 g of graphite powder into 25 mL of concentrated sulfuric acid by ice bath method, add 0.0525 g of KMnO under magnetic stirring 4 , stir evenly, when the temperature rises to 35°C, add 35 mL of deionized water, stir for 30 min, then add 15 mL of 30% H 2 o 2 , after stirring evenly, the product was collected by centrifugation and repeatedly washed with 5% HCl solution, deionized water and acetone to obtain graphite oxide nanosheets.

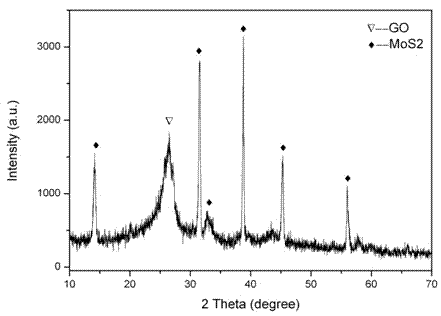

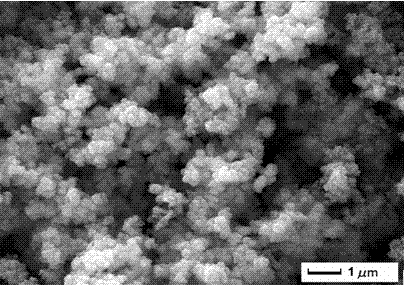

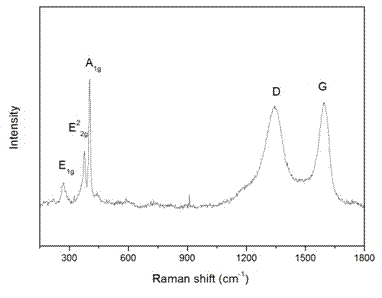

[0025] (2) Graphene / MoS 2 Preparation of nanocomposites: Dissolve 1.21 g of sodium molybdate in 50 mL of deionized water, add 1.08 g of sodium thiocyanate as a sulfur source and reducing agent under magnetic stirring, then add 0.5 g of sodium chloride, and stir evenly. Add 0.03 g of graphene oxide nanosheets prepared according to step 1), ultrasonically treat the above mixed solution to fully disperse the graphite oxide in the solution, and the pH value of the solution is 6, and ...

Embodiment 2

[0028] Graphene oxide nanosheets were prepared by the method of step (1) in Example 1.

[0029] Dissolve 1.21 g of ammonium molybdate in 50 mL of deionized water, add 1.08 g of sodium thiocyanate under magnetic stirring as a sulfur source and reducing agent, then add 0.5 g of sodium chloride, stir well, then add 0.03 g of For the graphene oxide nanosheets prepared in step 1) of 1, the above mixed solution was ultrasonically treated for 2 h to fully disperse the graphene oxide in the solution, and the solution was adjusted with 0.2 mol / L NaOH and 0.2 mol / L HCl The pH value was 2, and then the mixed solution was transferred into a polytetrafluoroethylene-lined hydrothermal reaction kettle, sealed and then hydrothermally reacted at 200°C for 48 h, and the product was collected by centrifugation, washed with deionized water and absolute ethanol After 3 to 5 times, dry at 80°C for 2 h, and place the dried product in N 2 / H 2 heat treatment at 800 °C for 2 h under protection, the ...

Embodiment 3

[0031] Graphene oxide nanosheets were prepared by the method of step (1) in Example 1.

[0032]Dissolve 1.21 g of sodium molybdate in 50 mL of deionized water, add 1.08 g of sodium thiocyanate under magnetic stirring as a sulfur source and reducing agent, then add 0.5 g of sodium chloride, stir well, then add 0.0152 g of Example 1 step 1) for the prepared graphene oxide nanosheets, the above mixed solution was ultrasonically treated for 2 h to fully disperse the graphene oxide in the solution, and the solution was adjusted with 0.2 mol / L NaOH and 0.2 mol / L HCl The pH value of the mixture was 2, and then the mixture was transferred to a hydrothermal reaction kettle lined with polytetrafluoroethylene, sealed and then hydrothermally reacted at 200°C for 48 h, and the product was collected by centrifugation, and deionized water and anhydrous After washing with water and ethanol for 3 to 5 times, dry at 80°C for 2 h, and put the dried product in N 2 / H 2 heat treatment at 800 °C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com