Flotation separation method of refractory lead-zinc sulfide ore and sphalerite inhibitor of refractory lead-zinc sulfide ore

A lead-zinc sulfide and separation method technology is applied in the field of sphalerite inhibitor and flotation separation of refractory lead-zinc sulfide ores, and can solve the problems of high grinding cost, large amount of zinc sulfate, and high zinc mutual content, and achieves the The effect of reducing grinding cost, reducing grinding energy consumption, and strong inhibition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Flotation separation of refractory lead-zinc sulfide ore

[0037] The ore produced by a difficult-to-select lead-zinc sulfide mine in Yunnan is a typical lead-zinc mineral vein-like disseminated lead-zinc sulfide ore. The original ore contains 0.81% of Pb and 2.31% of Zn. The ore intercalation particle size D90<0.029mm, sphalerite intercalation particle size D90<0.026mm, part of the lead-zinc minerals are interlaced and contiguous, and belong to the refractory lead-zinc sulfide ore.

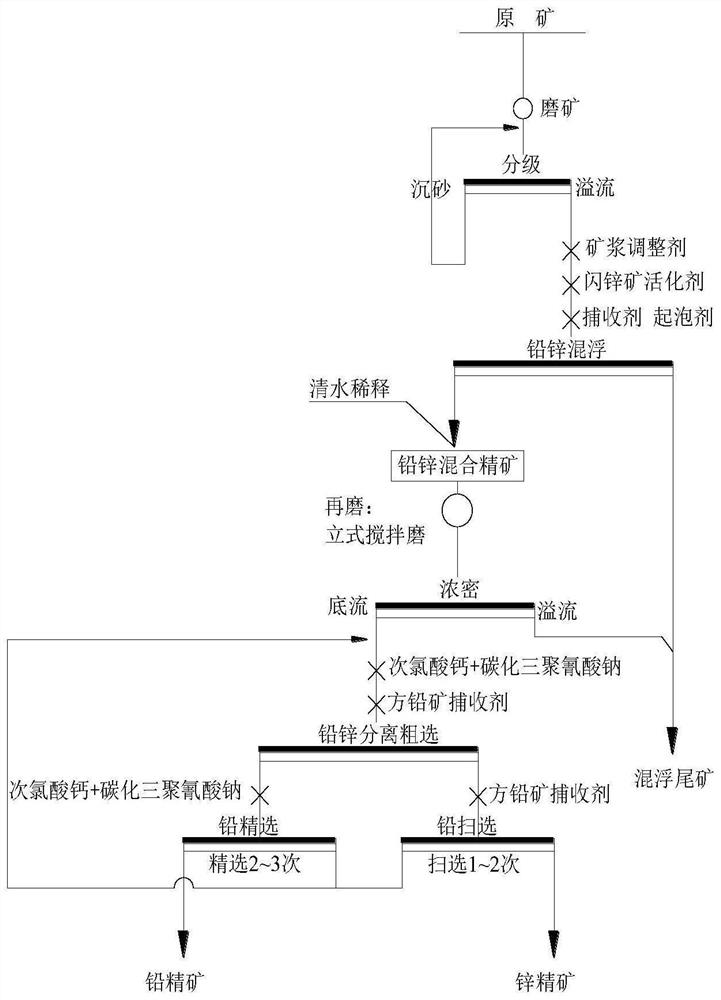

[0038] according to figure 1 The flotation separation process flow chart of the shown refractory lead-zinc sulfide ore processes the lead-zinc sulfide ore ore, comprising the following steps:

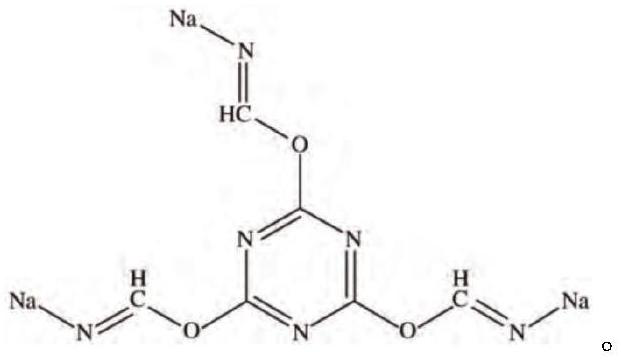

[0039] Preparation of sphalerite inhibitor for flotation separation of refractory lead-zinc ore sulfide: mix calcium hypochlorite and carbonized sodium cyanurate at a mass ratio of 1:2 to obtain sphalerite inhibitor.

[0040] The raw ore of a difficult-to-select lead-zinc sulfide mine in Yunnan is...

Embodiment 2

[0058] Flotation separation of a refractory lead-zinc sulfide ore in Guangxi

[0059] according to figure 1 The flotation separation process flow chart of the shown refractory lead-zinc sulfide ore processes the lead-zinc sulfide ore ore, comprising the following steps:

[0060] Preparation of sphalerite inhibitor for flotation separation of refractory lead-zinc sulfide ore: mix calcium hypochlorite and carbonized sodium cyanurate at a mass ratio of 1:4 to obtain sphalerite inhibitor.

[0061] The raw ore of a difficult-to-select lead-zinc sulfide mine in Yunnan is processed to -3mm after coarse crushing-secondary crushing-fine crushing, and then sent to a ball mill for grinding and grading treatment. The particle size of the graded products is controlled to be -0.074mm, accounting for 75%, and the graded products are sent to Add lime to the mixing tank to adjust the pH value to 11.5, and then add copper sulfate, butyl xanthate, ethionyl nitrogen, and MIBC for lead-zinc mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com