Gold extracting agent and preparation method thereof

A gold extraction agent and raw material technology, applied in the field of gold extraction agent and its preparation, can solve the problems of poor direct leaching effect, interference, unsatisfactory gold extraction effect, etc., and achieve short leaching time, fast recovery, and convenient storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

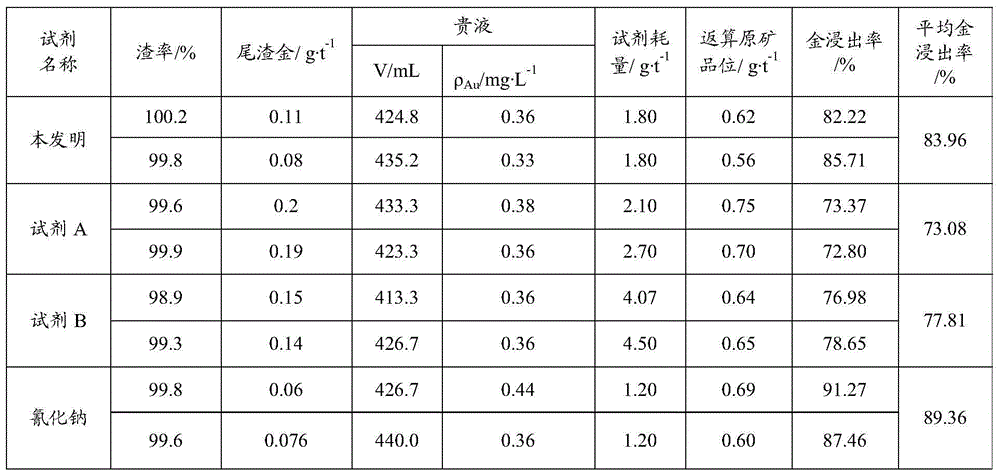

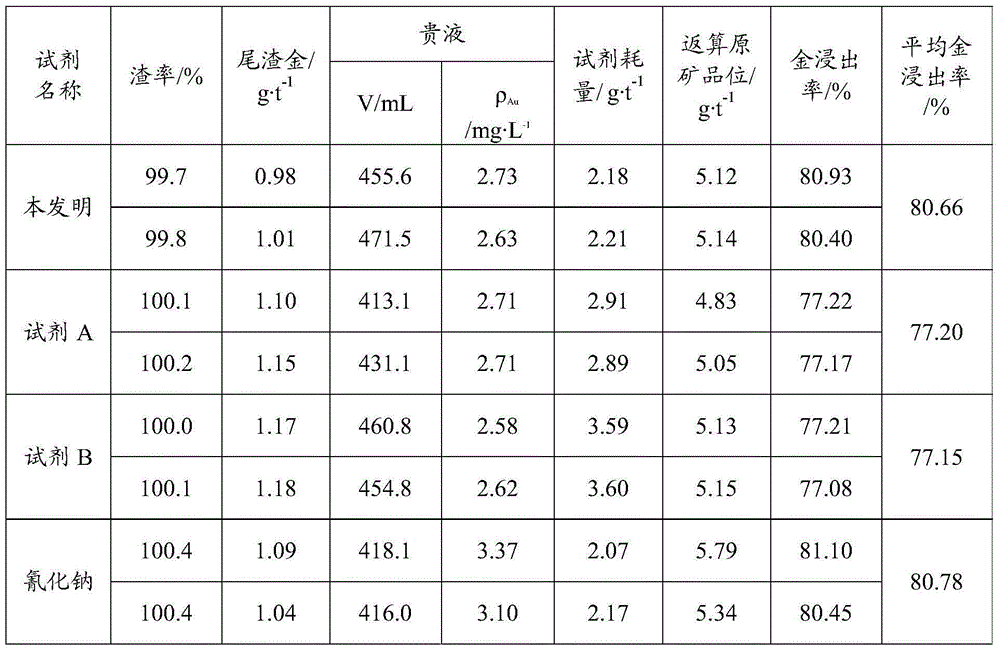

Examples

preparation example Construction

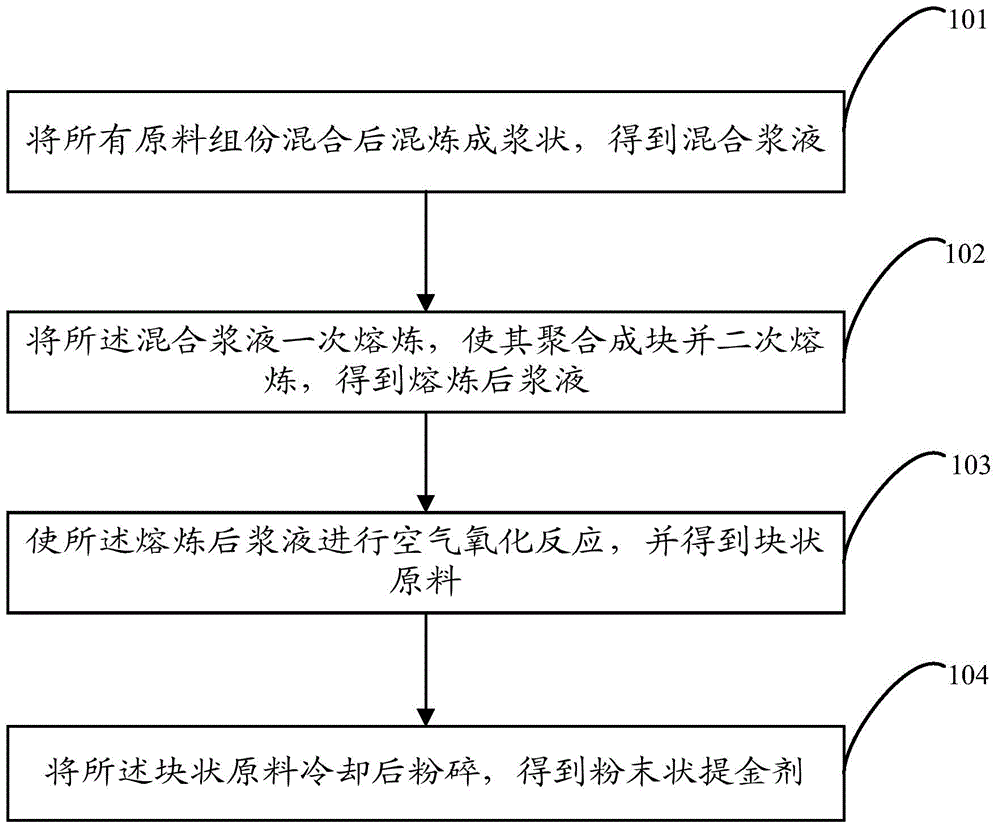

[0038] Please refer to figure 1 , the preparation method of the above-mentioned gold extraction agent that the present invention also provides, comprises the following steps:

[0039] Step 101: mixing all raw material components and kneading into a slurry to obtain a mixed slurry;

[0040] In step 101, after mixing the materials, they are kneaded under high temperature conditions, so that all components are melted and mixed, and a mixed slurry is obtained. As a preference, this step can specifically be carried out according to the following operations: after mixing all the raw material components, airtightly knead at 480-520°C for 30-40 minutes, and then perform a natural oxidation reaction under ventilated conditions for 60-70 minutes; The process can realize the melting of all components, and then ventilate after melting, so that the outside air can contact the slurry, and carry out a natural oxidation reaction, so that the gold extraction agent contains oxygen and improve ...

Embodiment 1

[0052] The gold extracting agent provided by the embodiments of the present invention, in parts by weight, its raw material components include:

[0053] 12 parts of sodium hexametaphosphate, 7 parts of sodium cyanate, 9.4 parts of sodium ferrocyanide, 10.3 parts of sodium sulfide, 13.3 parts of sulfur, 10.8 parts of sodium bromide, 6.7 parts of sodium chloride, 8.6 parts of manganese dioxide, 12.2 parts of urea parts, industrial soda ash 9.7 parts.

[0054] Preparation

[0055] S11: After mixing all raw material components, airtight kneading at 480°C for 30 minutes, and then natural oxidation reaction under ventilated conditions for 60 minutes;

[0056] Wherein, the natural oxidation reaction is controlled at 480-520°C.

[0057] S12: smelting the mixed slurry once to aggregate it into blocks and smelting it a second time to obtain the smelted slurry;

[0058] Wherein, the temperature of the first smelting is 850°C, and the time is 4 hours;

[0059] The temperature of the s...

Embodiment 2

[0065] The gold extracting agent provided by the embodiments of the present invention, in parts by weight, its raw material components include:

[0066] 12.4 parts of sodium hexametaphosphate, 7.4 parts of sodium cyanate, 9.8 parts of sodium ferrocyanide, 10.7 parts of sodium sulfide, 13.7 parts of sulfur, 10.4 parts of sodium bromide, 6.3 parts of sodium chloride, 8.2 parts of manganese dioxide, 11.8 parts of urea parts, industrial soda ash 9.3 parts.

[0067] Preparation

[0068] S21: After mixing all the raw material components, airtight kneading at 520°C for 30-40 minutes, and then natural oxidation reaction under ventilated conditions for 60-70 minutes;

[0069] Wherein, the natural oxidation reaction is controlled at 480-520°C;

[0070] S22: smelting the mixed slurry once to aggregate it into blocks and smelting it a second time to obtain a smelted slurry;

[0071] Wherein, the temperature of the first smelting is 850°C, and the time is 5 hours;

[0072] The temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com