Environmental-protection gold leaching agent and preparation method thereof

A gold leaching agent and environmental protection technology, applied in the field of environmental protection gold leaching agent and its preparation, can solve the problems of complex process, high production cost, and difficult to handle gold mines, and achieve simple synthesis process, high utilization rate of raw materials, and gold leaching The effect of superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

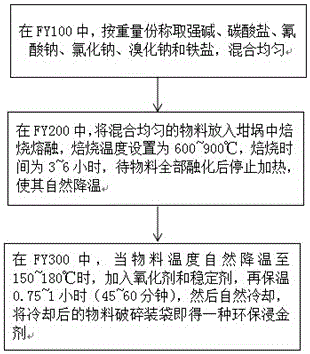

[0026] According to the second aspect of the present invention, the preparation method of environment-friendly gold leaching agent is provided, comprising:

[0027] Step 1, take strong alkali, carbonate, sodium cyanate, sodium chloride, sodium bromide and iron salt by weight, and mix uniformly;

[0028] Step 2, put the uniformly mixed material into the crucible to roast and melt, the roasting temperature is set at 600-900°C, the roasting time is 3-6 hours, stop heating after all the materials are melted, and let it cool down naturally;

[0029] Step 3. When the temperature of the material is naturally lowered to 150-180°C, add an oxidizing agent and a stabilizer, keep it warm for 0.75-1 hour (45-60 minutes), then cool it naturally, crush the cooled material and pack it into a bag to obtain an environmentally friendly dip gold agent.

[0030] Further, in step 2, the reaction waste gas can be adsorbed by using a spray tower or an adsorption liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com