Environment-friendly gold leaching agent and preparation process thereof

A kind of leaching agent, environment-friendly technology, applied in the field of environment-friendly gold leaching agent, can solve the problems of toxic and harmful components of cyanide leaching gold, slow gold leaching speed, large drug consumption, etc., and achieve fast gold leaching speed and high recovery rate High, improve the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

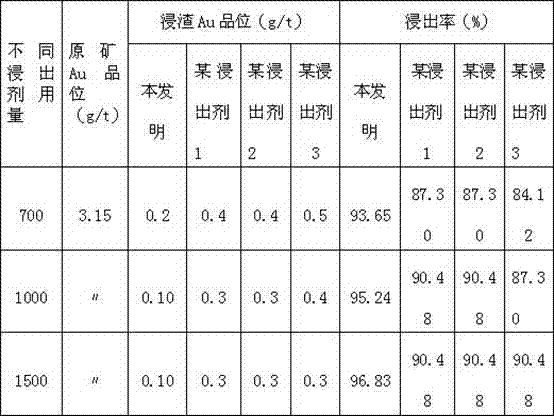

Examples

Embodiment 1

[0017] An environment-friendly gold leaching agent, which comprises the following components in parts by mass: 20 parts of urea, 20 parts of thiourea, 8 parts of sodium cyanate, 25 parts of ferric oxide, 18 parts of sodium carbonate, 30 parts of sodium hydroxide.

Embodiment 2

[0019] An environment-friendly gold leaching agent, which comprises the following components in parts by mass: 60 parts of urea, 15 parts of thiourea, 25 parts of sodium cyanate, 15 parts of ferric oxide, 30 parts of sodium carbonate, 20 parts of sodium hydroxide.

Embodiment 3

[0021] An environment-friendly gold leaching agent, which comprises the following components in parts by mass: 50 parts of urea, 10 parts of thiourea, 40 parts of sodium cyanate, 10 parts of ferric oxide, 20 parts of sodium carbonate, Sodium hydroxide 10 parts.

[0022] The preparation process of Examples 1-3 is as follows: prepare the materials according to the ratio of raw materials, add them into the mixing agitator and mix them evenly, then add them into the melting reaction furnace, control the reaction temperature at 800-1000°C, react at high temperature for 1-3 hours, and cool down to normal temperature The pulverizer pulverizes, and then sieves and packs to obtain an environment-friendly gold extractant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com