Method for extracting fucoxanthin from brown algae

A fucoxanthin and brown algae technology, applied in the direction of organic chemistry, etc., can solve problems such as affecting the purification of fucoidin and the inability of samples to be dried.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The light-dried kelp was washed twice with tap water at room temperature to remove surface silt, floating organisms, colloids and other sundries, then air-dried naturally in the shade, and then crushed with a grinder produced by Jiangyin Xinyou Machinery Manufacturing Co., Ltd. 30 mesh or less, and then stored in a refrigerator at a temperature of 4°C until use.

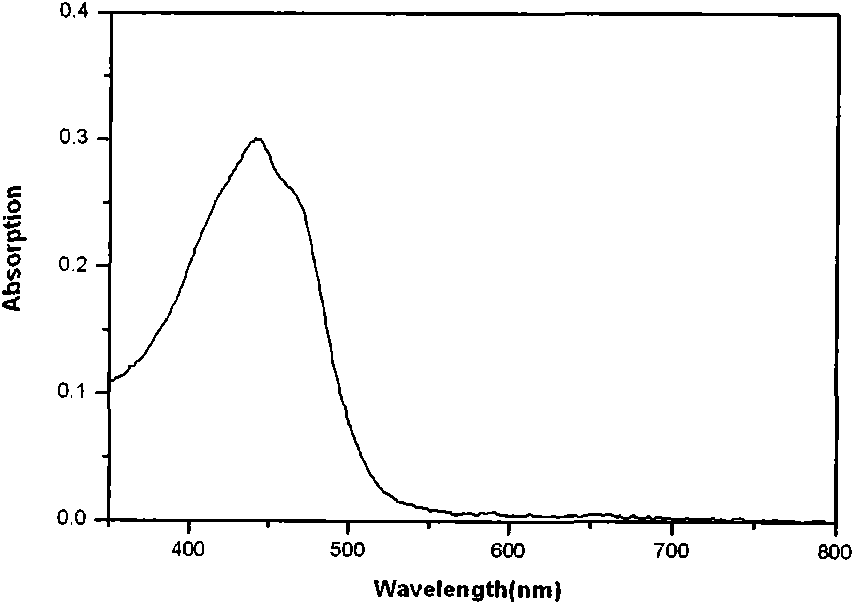

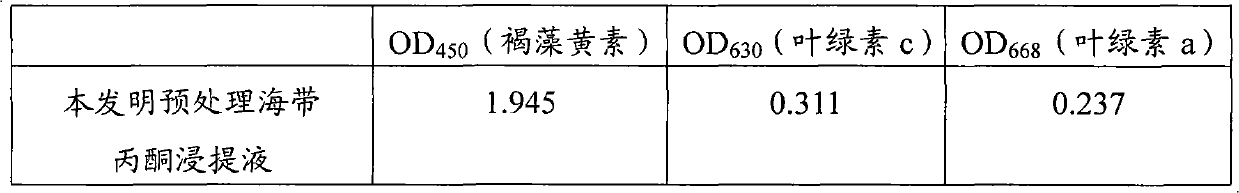

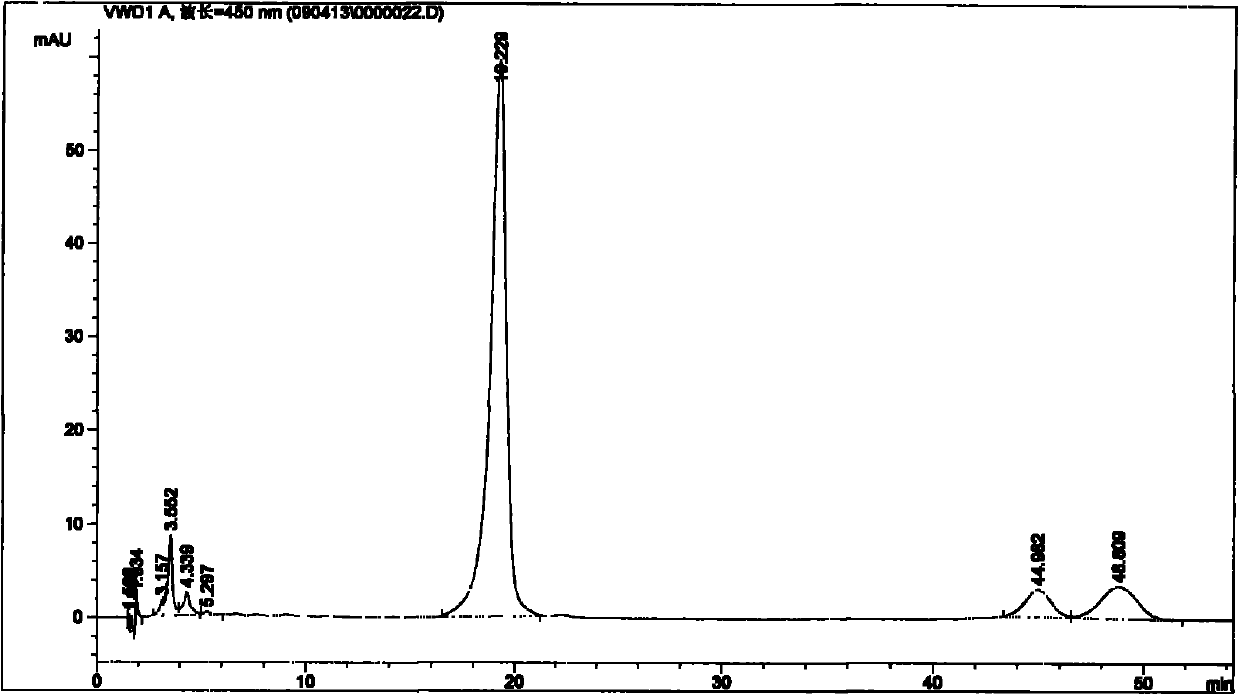

[0072] Put 1g of crushed kelp in an iodine bottle and soak it in 4ml of water for 10 minutes until the kelp fully absorbs water and the surface of the kelp becomes dry. Then, it was leached with 5ml of acetone water-soluble organic solvent for 30min at room temperature and protected from light, and the leaching was repeated twice. At the same time, under the same conditions, the same kelp without swelling treatment was leached with acetone or 75% by volume acetone aqueous solution for 30 min, and the leaching was repeated twice. The extracts were collected respectively and centrifuged to remove insoluble matt...

Embodiment 2

[0081] This embodiment is carried out in the same manner as in Example 1, except that 5 ml of acetone, dimethyl sulfoxide, and methanol water-soluble solvents are used for leaching once for 30 min. The results of these assays are listed in Table 2.

[0082] Table 2: Absorbance values of fucoxanthin, chlorophyll c and chlorophyll a when extracted with acetone, DMSO and methanol (diluted 3 times)

[0083]

[0084] It can be clearly seen from Table 2 that the efficiency of extracting fucoxanthin with acetone after the method of the present invention is much higher than that of using other solvents (DMSO, methanol) under the same conditions.

Embodiment 3

[0086] The present embodiment is carried out in the same manner as in Example 1, except that the pulverized sea-tangle of 1 g is extracted once with 4, 5, 6, and 7 ml of acetone for 30 minutes. The results of these assays are listed in Table 3.

[0087] Table 3: Absorbance values of fucoxanthin, chlorophyll c and chlorophyll a when extracted with different amounts of acetone (diluted 3 times)

[0088]

[0089] It can be clearly seen from Table 3 that under the method conditions of the present invention, when the ratio of the weight of kelp in grams to the volume of acetone in milliliters is 1:5, the efficiency of extracting fucoxanthin is better than other ratios.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com