Biological stirring cobalt-dipping technique for concentrate containing cobalt and sulfur

A technology of cobalt sulfur concentrate and a new process, which is applied in the direction of microorganisms, microorganisms, process efficiency improvement, etc., and can solve problems such as the use of sulfuric acid that cannot be solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

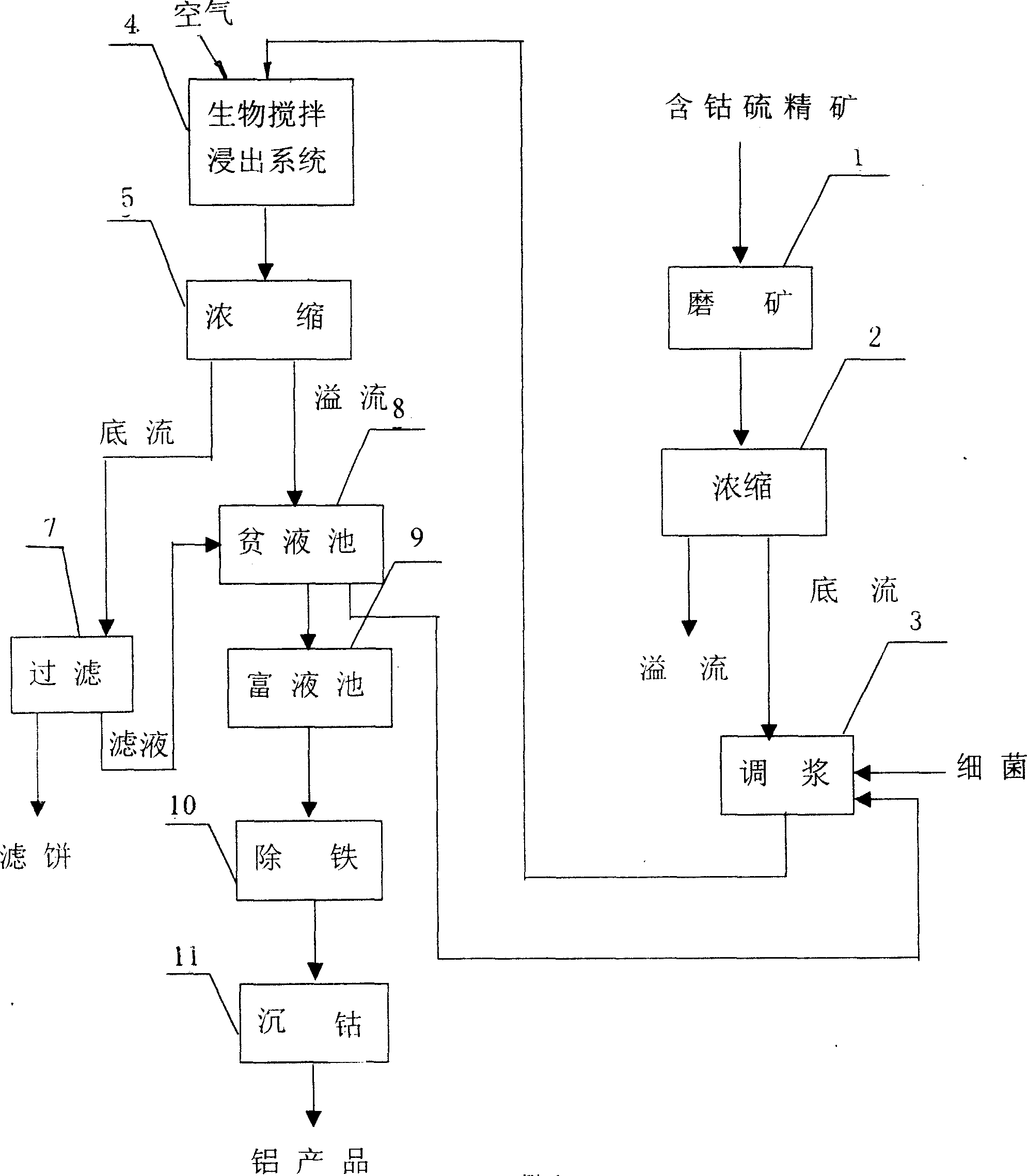

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment.

[0029] For example, a copper mine in western my country is a sulfide deposit containing a large amount of pyrite and a small amount of cobalt. There is no independent cobalt mineral in the iron sulfide ore, and the element cobalt is mixed into the iron sulfide in the form of isomorphism. The average copper content of the mine is 1.6%, the average sulfur content is 36%, and the average cobalt content is 0.1%. The main gangue minerals are quartz, feldspar, chlorite, sericite and carbonate minerals.

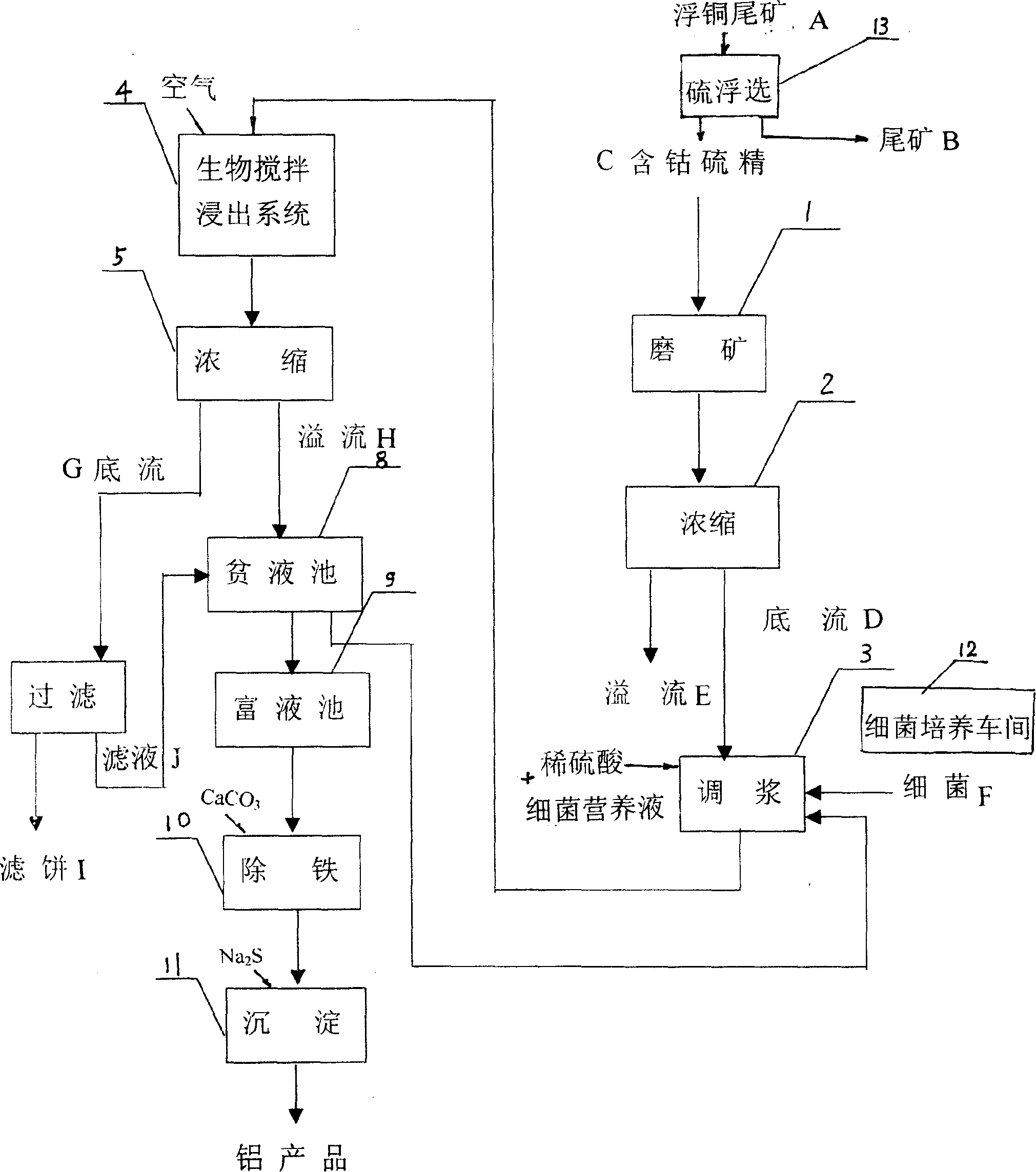

[0030] (1) if figure 2 As shown, the raw ore mined in the mine undergoes crushing, grinding, flotation and other processes to recover copper in the ore to obtain high-sulfur and cobalt-containing tailings A. Sulfur flotation 13 is carried out on the high-sulfur and cobalt-containing tailings with a flotation machine to obtain sulfur concentrate C containing 1% cobalt; the flotation taili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com