Novel technics of metallurgy mineral dressing flotation air inflation and special equipment

A special equipment, mineral flotation technology, applied in flotation, solid separation and other directions, can solve the problem that the effective volume of a single machine cannot keep up with the development needs, reduce the speed of mineral leaching/oxidation, and reduce the cut-off grade of useful minerals. Save power consumption, improve flotation recovery rate, and realize the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

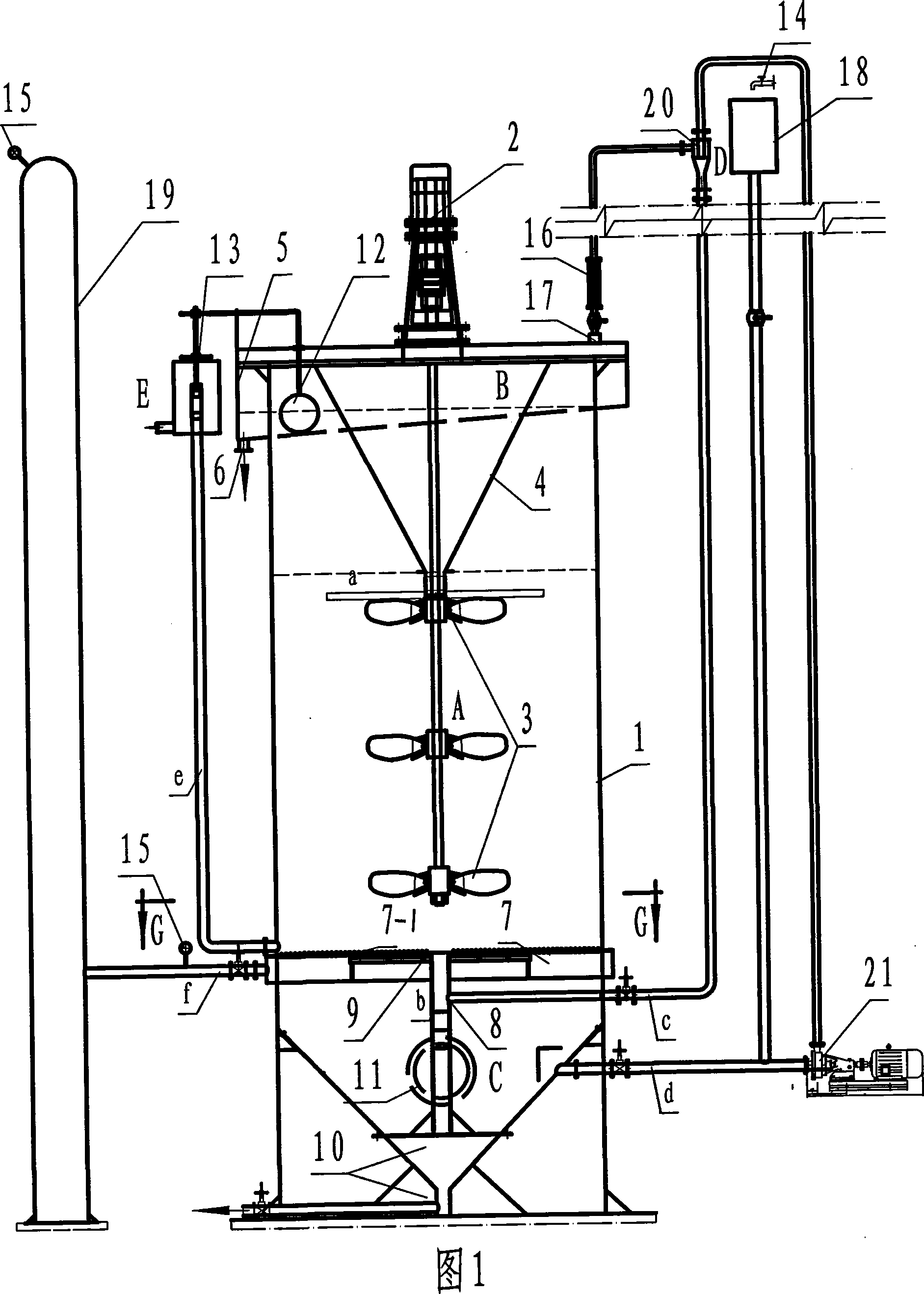

[0020] Embodiment 1, as shown in Fig. 1-Fig. 3, the device is mainly composed of host machine A, foam overflow system B, microbubble generating separator, microbubble generating system D and automatic liquid level pulp regulating mechanism E, etc. in,

[0021] The main engine A includes a stirring tank body 1, on which a reduction device 2 composed of a motor and a vertical reducer is installed, and an upper, middle and lower three-layer worm impeller stirring paddle 3 is installed in the stirring tank body 1, wherein The uppermost worm impeller agitator 3 is additionally equipped with a flat column pulp distribution blade a, and the worm impeller agitator 3 is connected to the reduction device 2 through a shaft;

[0022] The foam overflow system B is set in the main machine A, and includes a foam-push inverted cone-shaped tank 4 installed on the upper part of the stirring tank 1, and an annular foam overflow chute 5 is arranged on the upper end of the foam-push inverted cone-...

Embodiment 2

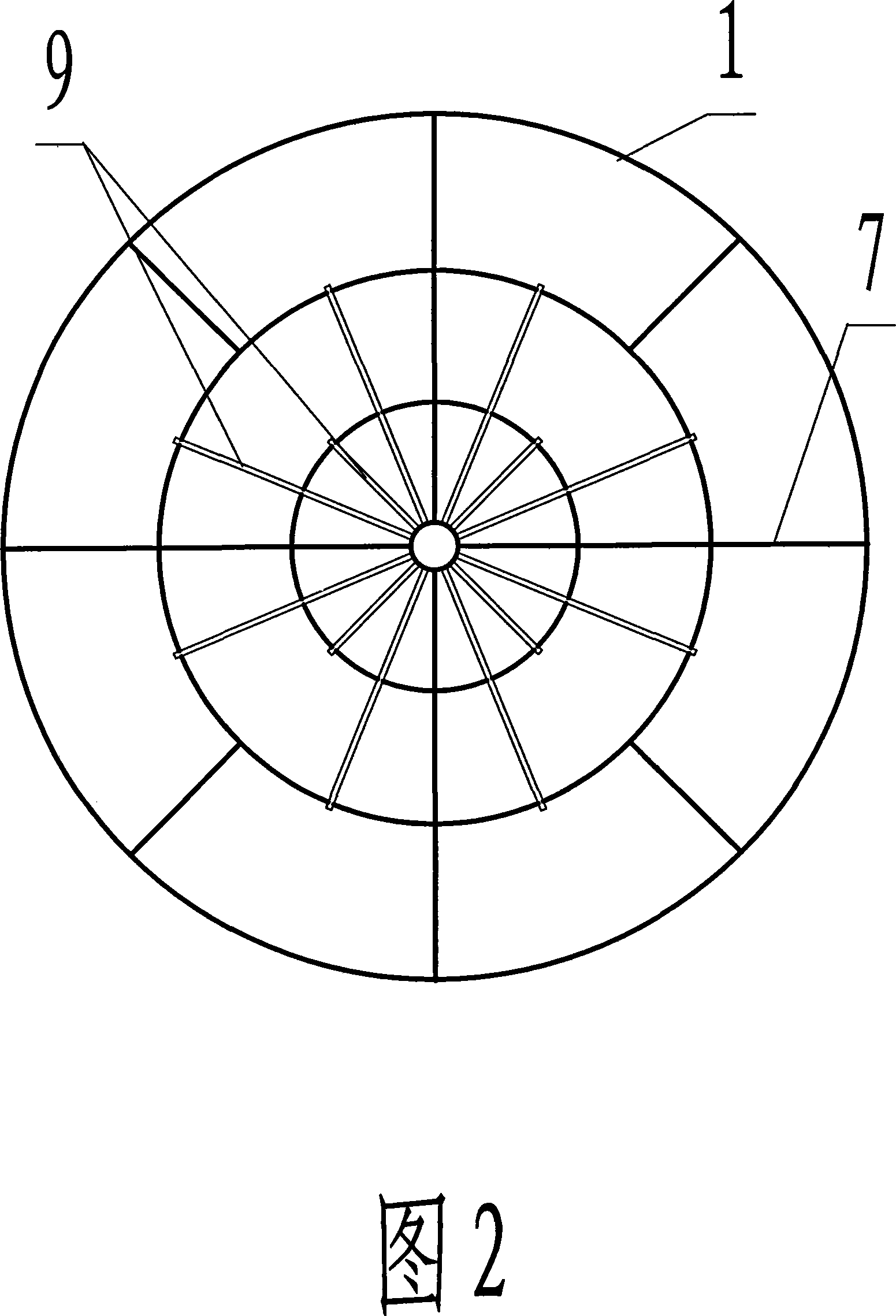

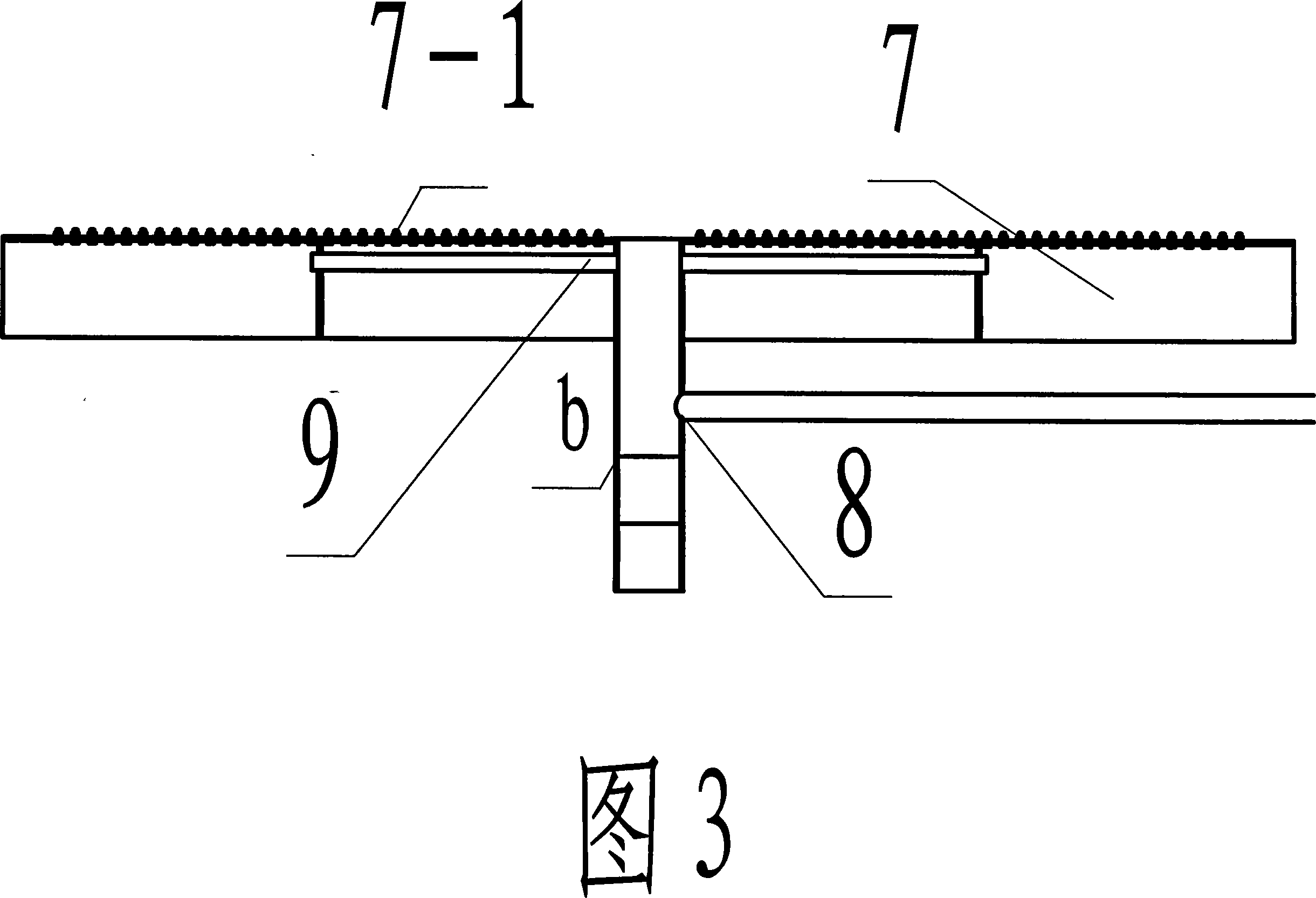

[0034] Embodiment 2, referring to Fig. 4, the structure of this example is basically the same as that of the previous example, the difference is that instead of using the water pump 21 and the vacuum water jet pump 20, the air can be directly supplied by the air compressor, and the air passes through the air inlet 17 , air flow meter 16, air supply pipe c, enter the air-water separation column tube 8, and then pass through some inflation distribution branch pipes 9, enter in each chamber of the microbubble inflation distributor 7, overflow from the inflation micropore 7-1, To achieve the purpose of microbubble inflation.

[0035]The present invention adopts the above-mentioned device to realize complete coverage of micro-bubble inflation with no dead angle, good inflation effect, high flotation recovery rate, sufficient oxidation reaction, higher and faster leaching speed, and achieves the purpose of strengthening oxidation leaching and improving recovery rate, and It can be f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com