Method for extracting gold and/or silver from sulfuric acid slag

A technology of sulfuric acid slag and ester-based thiourea, applied in the direction of improving process efficiency, etc., to achieve the effect of high selectivity and fast leaching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

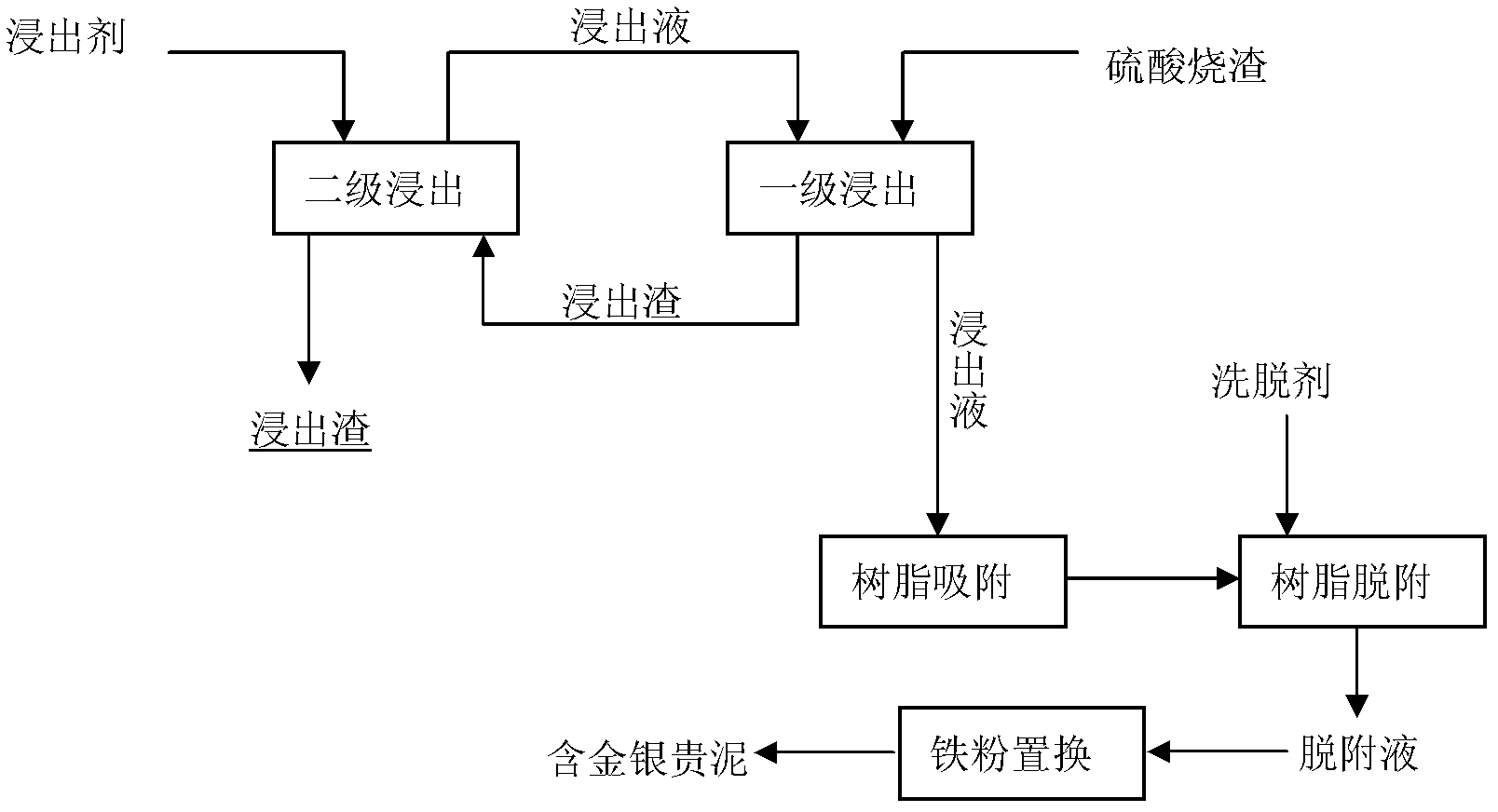

[0029] process such as figure 1 shown. Take 100 parts of sulfuric acid slag from a sulfuric acid factory in Jiangxi and add it to leaching tank 1, and take another 100 parts of sulfuric acid slag and add it to leaching tank 2. Add 300 parts of water, 4.5 parts of thiourea, and 55 parts of concentrated sulfuric acid to the two leaching tanks respectively. , control the temperature at 50 ° C for 8 hours, and obtain the leachate after filtration; move the leaching residue from leaching tank 2 into leaching tank 1, move the leaching liquid from leaching tank 1 into leaching tank 2, and add 300 parts of water and 4.5 parts of thiourea to leaching tank 1 , 55 parts of concentrated sulfuric acid, add 100 parts of sulfuric acid slag in the leaching tank 2, control the temperature to leaching at 50°C for 8h, and obtain the leachate after filtration; pass the leachate in the leaching tank 2 through the PTU-1 resin adsorption column at a speed of 6BV / h, The adsorption temperature is 18°...

Embodiment 2

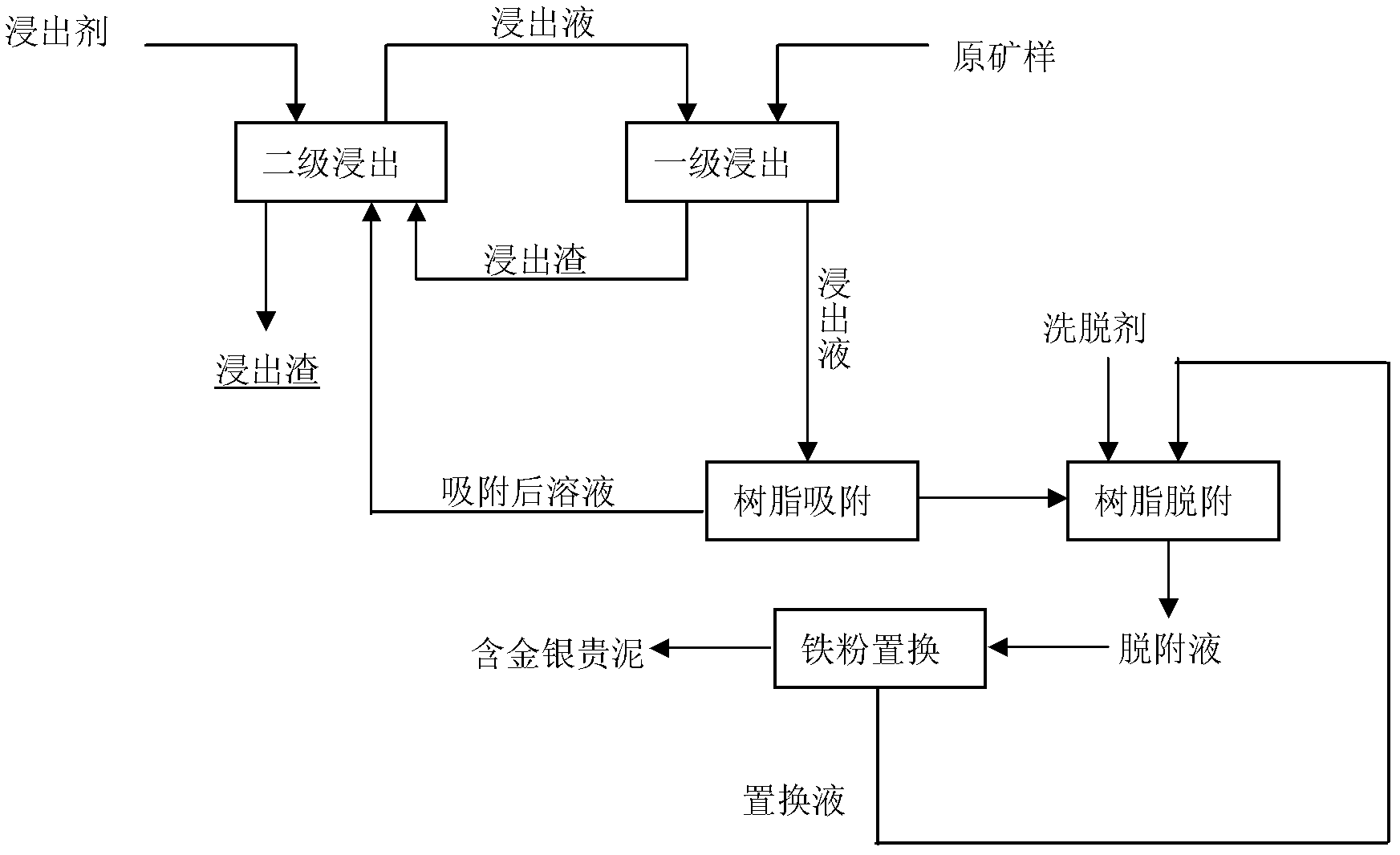

[0031] process such as figure 2 shown. Take 100 parts of sulfuric acid slag from a sulfuric acid factory in Jiangxi and add it to leaching tank 1, and add another 100 parts of sulfuric acid slag to leaching tank 2. Add 300 parts of water, 4 parts of thiourea, and 50 parts of concentrated sulfuric acid to the two leaching tanks respectively. , control the temperature at 50°C for 8 hours, and obtain the leach solution after filtration; move the leaching residue from leaching tank 2 into leaching tank 1, move the leaching solution from leaching tank 1 into leaching tank 2, and add 300 parts of water and 1 part of thiourea to leaching tank 1 , 15 parts of concentrated sulfuric acid, add 100 parts of sulfuric acid slag to the leaching tank 2, control the temperature at 50 ° C for 8 hours, and obtain the leaching solution after filtration; pass the leaching solution in the leaching tank 2 through the PTU-2 resin adsorption column at a speed of 6BV / h , the adsorption temperature is...

Embodiment 3

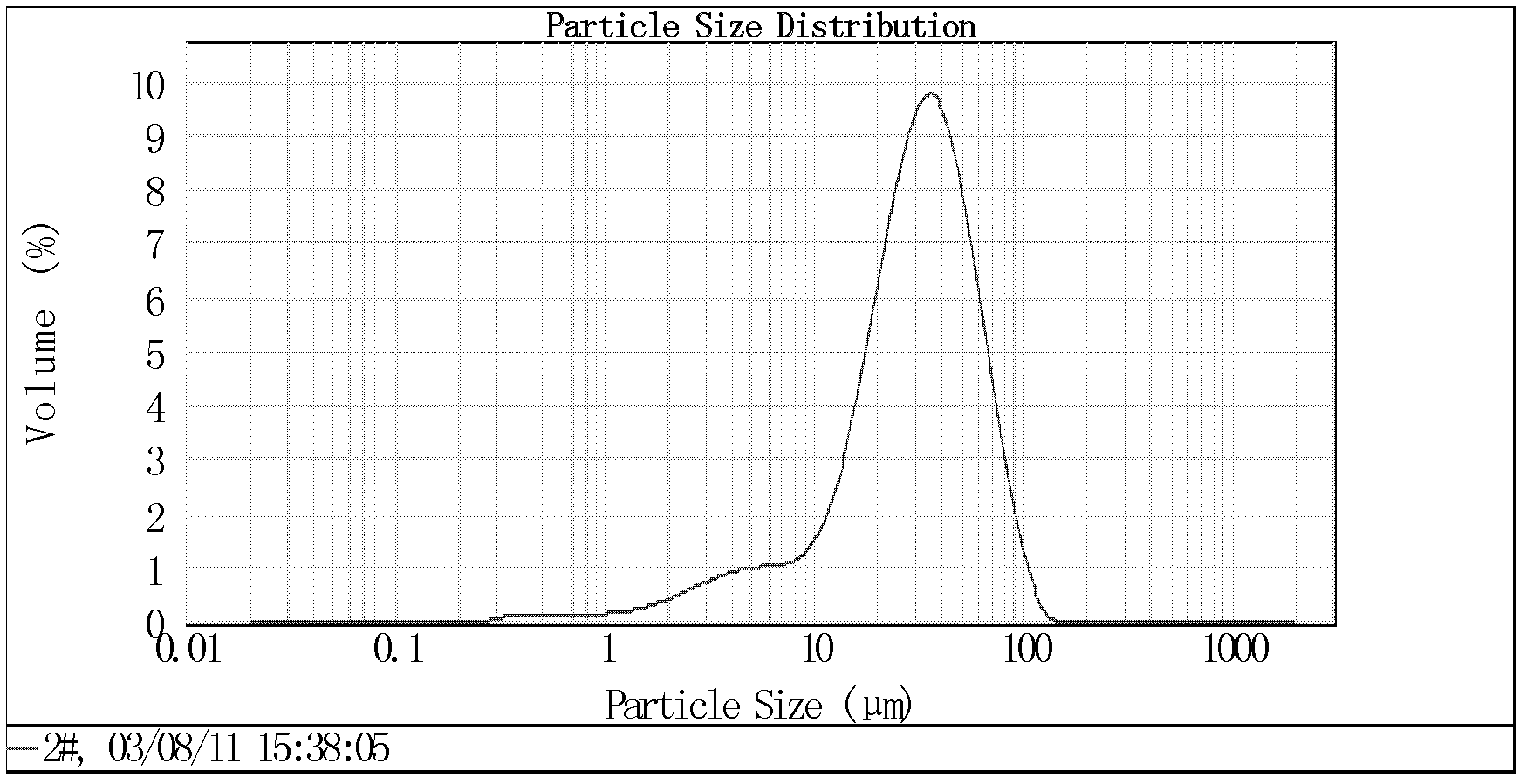

[0033] Carry out the experiment by the operating procedure of embodiment 2, in the circulation experiment, the leaching agent that leaching tank 2 adds is 300 parts of water, 2 parts of thiourea, 15 parts of sulfuric acid, the used adsorbent of adsorption process is PTU-3 resin, all the other operations are all the same. Same as implementation 2. The overall recoveries for gold and silver were 81.7% and 70.7%, respectively. The particle size distribution and XRD pattern of sulfuric acid slag before and after leaching are as follows Figure 3-6 shown. It can be seen from the figure that the particle size distribution and XRD diffraction peaks of sulfuric acid slag are basically unchanged before and after leaching, indicating that the leaching process does not change the particle size and crystal form of sulfuric acid slag, and does not affect its further smelting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com