Method for comprehensively recovering cobalt, copper and iron in cobalt-copper alloy

A cobalt-copper alloy, all-wet technology, applied in the field of comprehensive recovery of cobalt, copper and iron in cobalt-copper alloy, can solve the problems of low leaching rate, low consumption of raw materials, low production cost, etc. The effect of high consumption and efficient extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

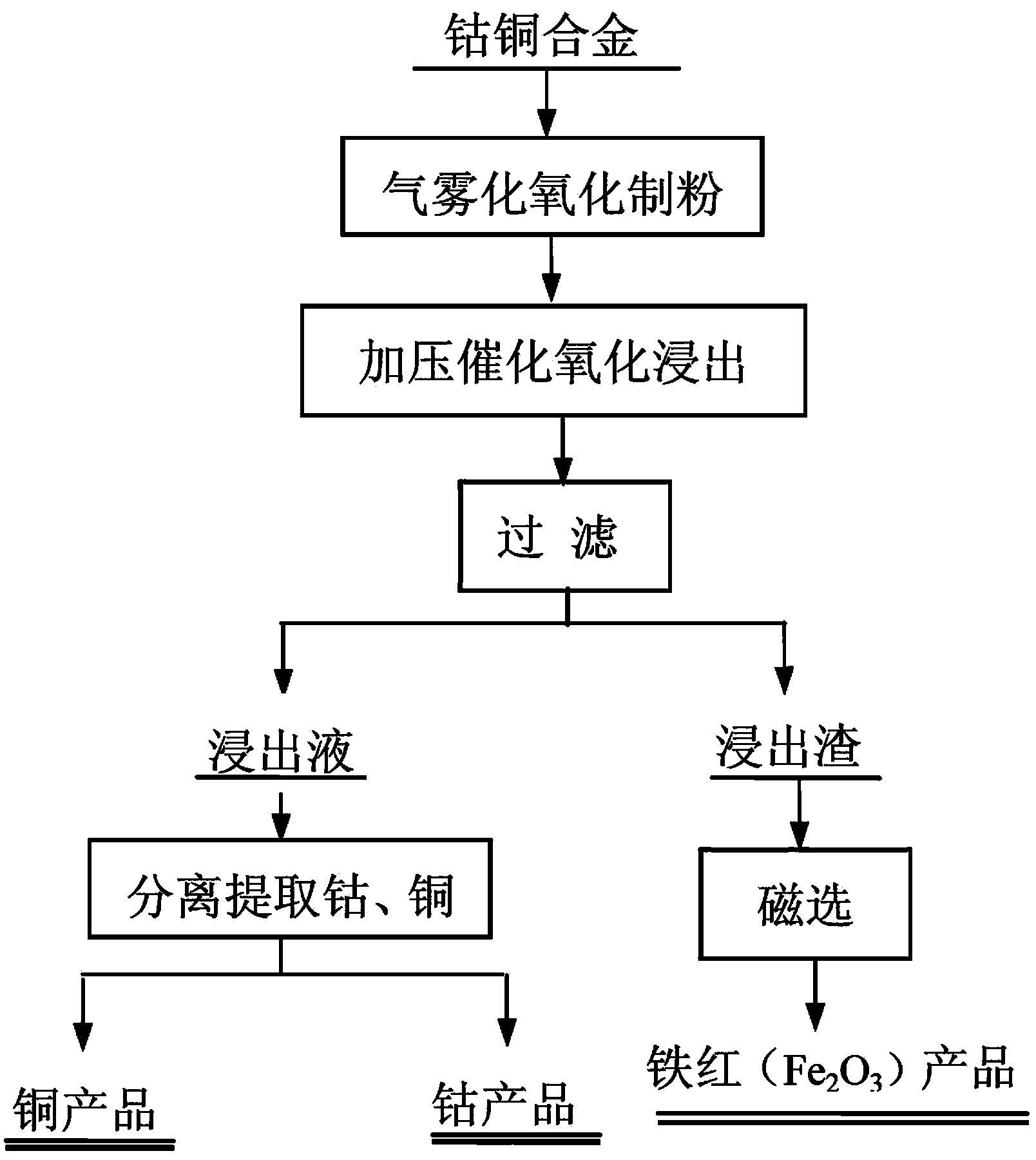

[0034] Kind of like figure 1 The method for comprehensively recovering cobalt, copper, and iron in a cobalt-copper alloy of the present invention includes the following steps:

[0035] (1) Gas atomized oxidation powder production: In the gas atomized powder production equipment, add 60 kilograms of cobalt-copper alloys with different particle sizes. At a temperature of 1450 ℃, the cobalt-copper alloy is fully melted and the alloy melt is evenly mixed. Constant temperature for 40 minutes; the molten alloy is atomized and oxidized with oxygen at a pressure of 5MPa, and the obtained powder is sieved through a -200 mesh sieve, and the sieve is returned to the gas atomization milling equipment for powder production, and the under sieve is prepared for subsequent use Pressurized catalytic oxidation leaching step.

[0036] (2) Pressurized catalytic oxidation leaching: The cobalt-copper alloy powder treated in step (1) is subjected to catalytic oxidation leaching in a pressurized kettle, ...

Embodiment 2

[0040] Kind of like figure 1 The method for comprehensively recovering cobalt, copper, and iron in a cobalt-copper alloy of the present invention includes the following steps:

[0041] (1) Gas atomized oxidation powder production: In the gas atomized powder production equipment, add 60 kilograms of cobalt-copper alloys with different particle sizes. At a temperature of 1550 ℃, the cobalt-copper alloy is fully melted and the alloy melt is evenly mixed. Constant temperature for 40 minutes; the molten alloy is atomized and oxidized with oxygen at a pressure of 6 MPa to make powder. The resulting powder is sieved through a -200 mesh sieve. The sieve is returned to the gas atomization milling equipment for powder making, and the under sieve is prepared for subsequent use The pressurized catalytic oxidation leaching step.

[0042] (2) Pressurized catalytic oxidation leaching: the cobalt-copper alloy powder treated in step (1) is subjected to catalytic oxidation leaching in a pressurized...

Embodiment 3

[0046] Kind of like figure 1 The method for comprehensively recovering cobalt, copper, and iron in a cobalt-copper alloy of the present invention includes the following steps:

[0047] (1) Gas atomized oxidation powder production: In the gas atomized powder production equipment, add 60 kilograms of cobalt-copper alloys with different particle sizes. At a temperature of 1550 ℃, the cobalt-copper alloy is fully melted and the alloy melt is evenly mixed. Constant temperature for 50 minutes; use oxygen at a pressure of 5.5MPa to atomize and oxidize the molten alloy to make powder. The resulting powder is sieved through a -200 mesh sieve, and the sieve is returned to the gas atomization milling equipment for powder making, and the under sieve is ready for use The subsequent pressurized catalytic oxidation leaching step.

[0048] (2) Pressurized catalytic oxidation leaching: the cobalt-copper alloy powder treated in step (1) is subjected to catalytic oxidation leaching in a pressurized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com