Oxygen direct-injection pure-hydrogen combustion engine and power system thereof

A combustion engine and engine technology, applied in the direction of combustion engine, internal combustion piston engine, gaseous engine fuel, etc., can solve the problems of being unable to promote, expensive, and consuming other resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

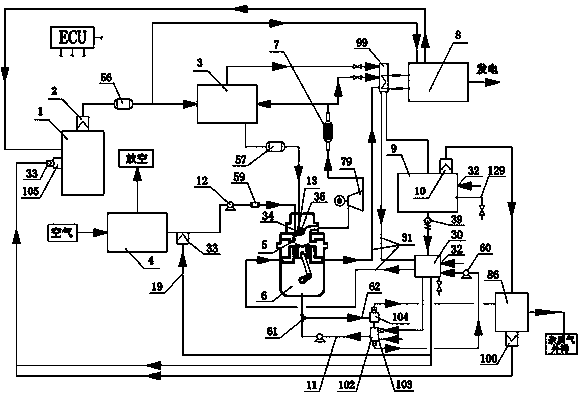

[0061] Oxygen direct injection pure hydrogen combustion internal combustion engine power system of the present invention such as figure 1 As shown, it includes ECU, hydrogen fuel engine, magnesium hydride storage tank 1, booster bed 3, pressure swing adsorption oxygen generator 4, condenser 99, exhaust gas expander 79, three-way catalytic converter 7, Clapp unit, hydrogen purification Unit 86, cooling water tank 30, booster pump 12, return water pump 60, gas-liquid separator 9, low-pressure hydrogen buffer tank 56, high-pressure hydrogen buffer tank 57, circulating water tank 102, No. 2 gas-liquid separator 104 and high-pressure oxygen buffer tank 59. Such as Figure 9 As shown, the hydrogen fuel engine is a two-stroke engine, including a cylinder 5 , a cylinder head 40 , a crankcase 35 and a water pan 6 . A spark plug 36, a hydrogen nozzle 13 and an oxygen nozzle 34 are arranged on the cylinder head, and an exhaust hole 41 is arranged on the cylinder wall. A crankshaft 45 ...

Embodiment 2

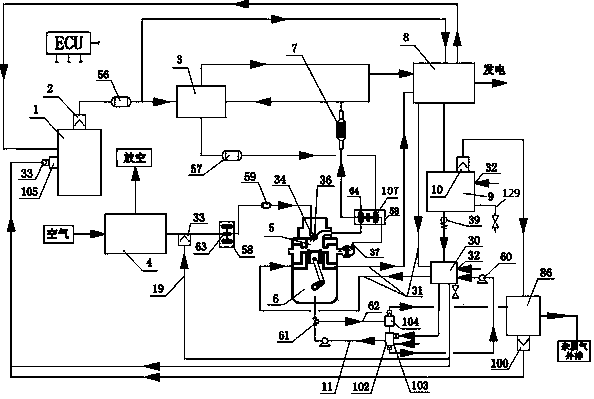

[0096] Another embodiment of the present invention is as figure 2 As shown, it includes ECU, hydrogen fuel engine, magnesium hydride storage tank 1, booster bed 3, pressure swing adsorption oxygen generator 4, three-way catalytic converter 7, composite Clapp unit, low-pressure hydrogen buffer tank 56, high-pressure hydrogen buffer tank 57. High-pressure oxygen buffer tank 59, hydrogen purification unit 86, gas-liquid separator 9, circulating water tank 102, No. 2 gas-liquid separator 104, cooling water tank 30 and turbocharger unit 58. The hydrogen outlet of the magnesium hydride storage tank is provided with a hydrogen filter membrane 2 , the gas outlet of the gas-liquid separator is provided with a gas filter membrane 10 , and the cooling water tank 30 and the gas-liquid separator 9 are provided with a drain port 129 . The circulating water tank 102 is provided with a lubricant adding port 103 and a drain port, the drain port is provided with a lubricant filter film, and th...

Embodiment 3

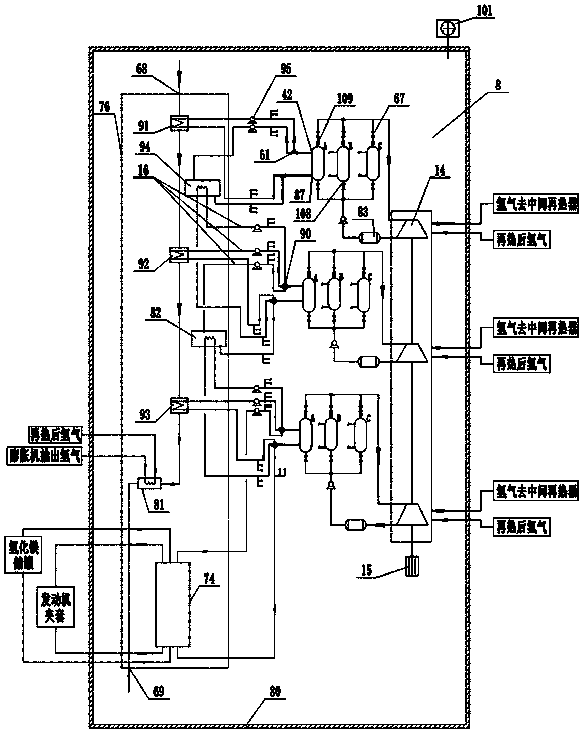

[0127] The third embodiment of the present invention is as Figure 8 As shown, it includes a hydrogen fuel engine, a magnesium hydride storage tank 1, a pressure swing adsorption oxygen generator 4, a three-way catalytic converter 7, a booster pump 12, an exhaust waste heat utilization unit, a gas-liquid separator 9, a cooling water tank 30, and a hydrogen purification unit 86 , circulating water tank 102 , No. 2 gas-liquid separator 104 , turbocharger unit 58 , low-pressure hydrogen buffer tank 56 and high-pressure oxygen buffer tank 59 . The hydrogen outlet of the magnesium hydride storage tank is provided with a hydrogen filter membrane 2 , the gas outlet of the gas-liquid separator is provided with a gas filter membrane 10 , and the cooling water tank 30 and the gas-liquid separator 9 are provided with a drain port 129 . The circulating water tank 102 is provided with a lubricant adding port 103 and a drain port, the drain port is provided with a lubricant filter film, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com