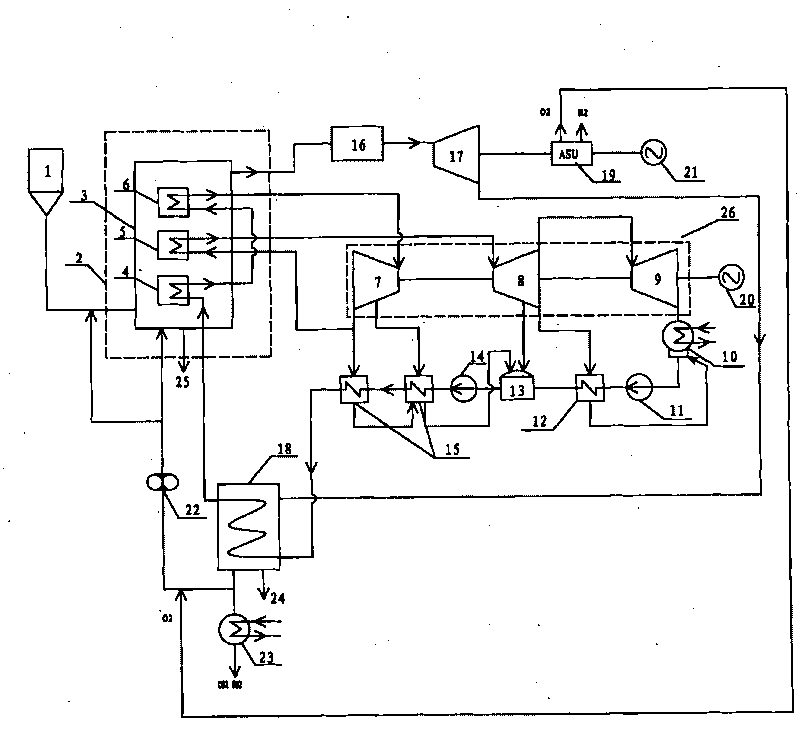

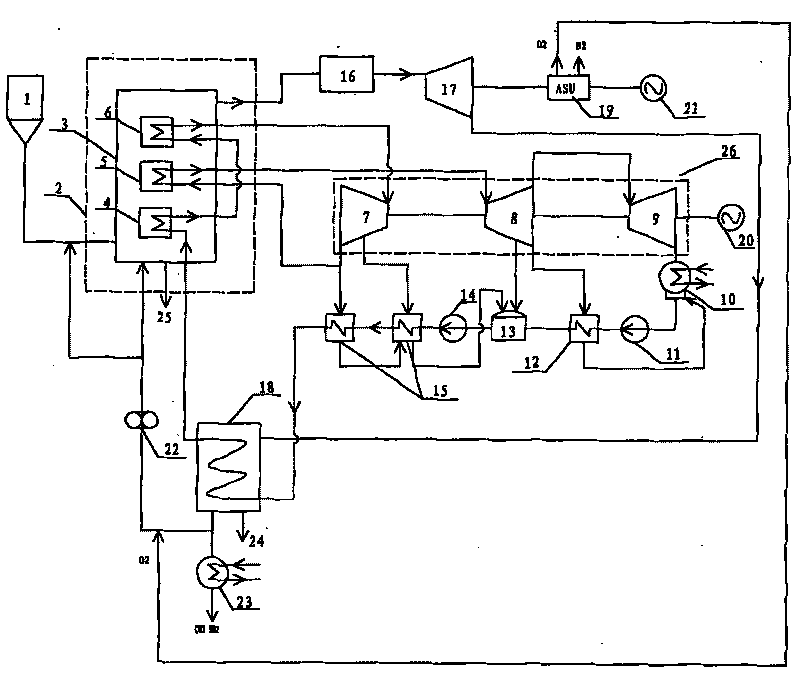

Combined cycle generation system of high-pressure oxygen-enriched combustion fluidized bed

A combined cycle power generation and oxygen-enriched combustion technology, applied in fluidized bed combustion equipment, combustion methods, combustion types, etc., can solve the problems of not considering emission reduction, low efficiency, etc., to reduce the power consumption of oxygen production and improve the efficiency , the effect of increasing the output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The system of the present invention starts from air separation oxygen production, boiler combustion and heat exchange, gas turbine work, until flue gas captures CO 2 The whole process is maintained at high pressure, which not only realizes the high concentration of CO after combustion 2 , combined with the advantages of high efficiency of the combined cycle, effectively avoiding the pressure rise (air separation oxygen production) - drop (atmospheric combustion process) - rise (atmospheric CO 2 compressed into a liquid process), thereby greatly reducing energy loss. It is a technically feasible and economically acceptable solution. Combine below figure 1 Embodiments of the present invention are further described:

[0014] A. Working medium circulation system: The fluidized bed 3 is set in the pressure tank 2. Since the volume of the pressurized oxygen-enriched combustion fluidized bed is significantly smaller than that of the conventional fluidized bed, too many heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com