Air separation method utilizing liquefied natural gas cold energy to produce high pressure oxygen rich gas

A technology for liquefied natural gas and oxygen-enriched gas, which is applied in the direction of cold treatment separation, liquefaction, refrigeration and liquefaction, etc., can solve the problems of high production cost of liquid oxygen, high energy consumption of oxygen production, limited market scale, etc., to save equipment investment costs, High safety performance and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

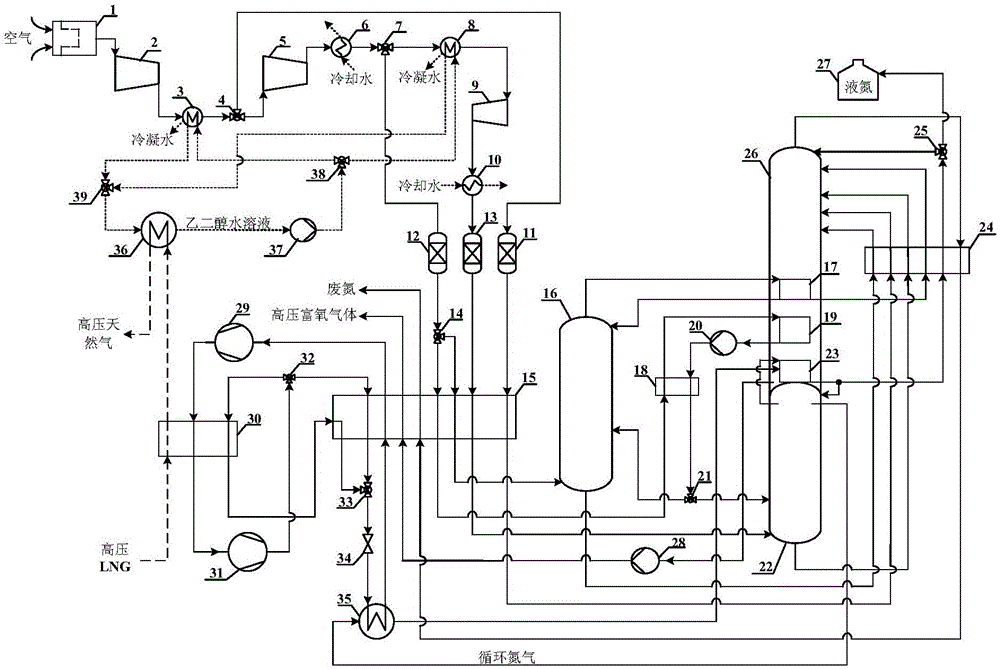

[0053] Such as figure 1 As shown, a kind of air separation method utilizing the cold energy of liquefied natural gas to produce high-pressure oxygen-enriched gas comprises the following steps and process conditions:

[0054] The molar composition of liquefied natural gas (LNG) at the receiving station is: methane 88.78%, ethane 7.54%, propane 2.59%, isobutane 0.45%, butane 0.56%, nitrogen 0.08%; the pressure of LNG entering the air separation unit is 10MPa, The temperature is about -150°C. The molar composition of the air raw material is: nitrogen 77.31%, oxygen 20.73%, argon 0.92%, CO 2 0.04%, water 1.02%; air pressure 0.101MPa, temperature 15°C. The isentropic efficiency of all compressors is 0.82 and the mechanical efficiency is 0.97; the isentropic efficiency of all pumps (including water pumps, liquid oxygen pumps and liquid air pumps) is 0.75 and the mechanical efficiency is 0.97.

[0055] Specific steps are as follows:

[0056] (1) Air compression and purification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com