Automobile pure oxygen combustion engine system

A combustion engine and engine technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of combustion deterioration, soot level rise, large ablation, etc., to reduce emissions, achieve ultra-low emissions, and reduce particles The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

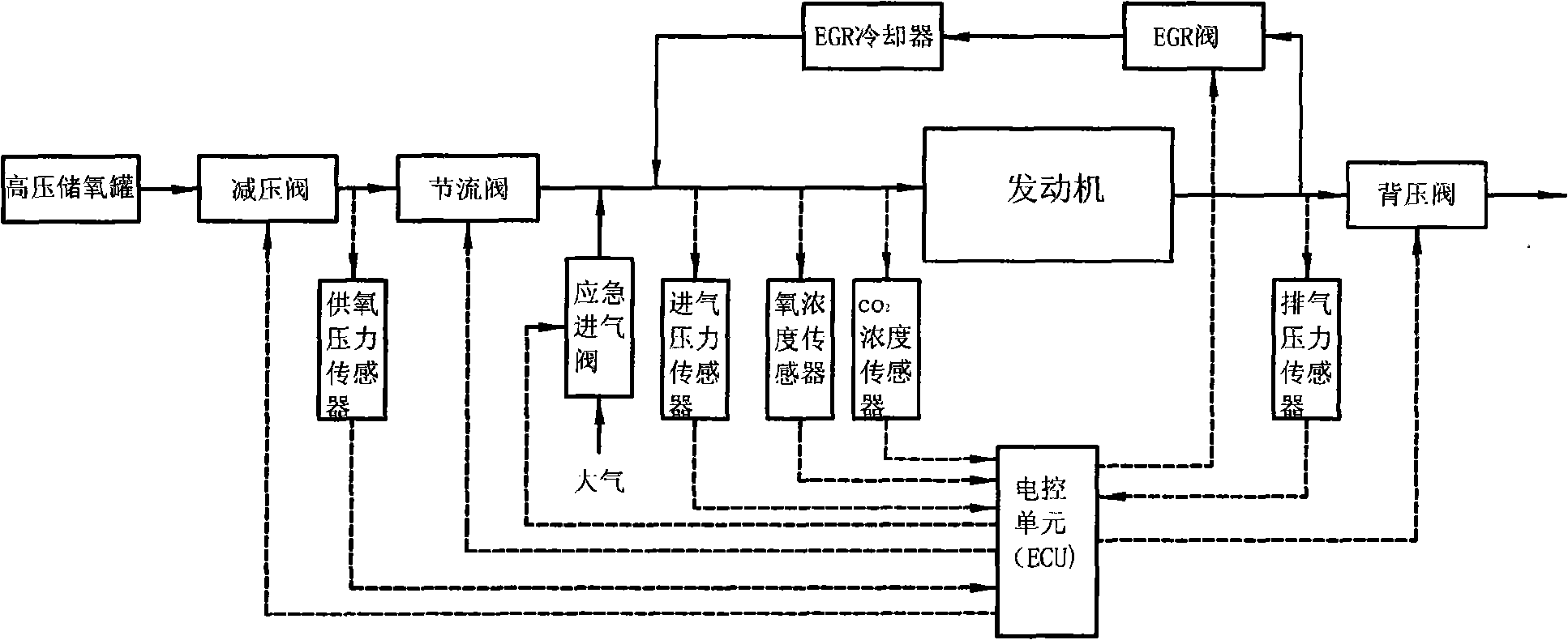

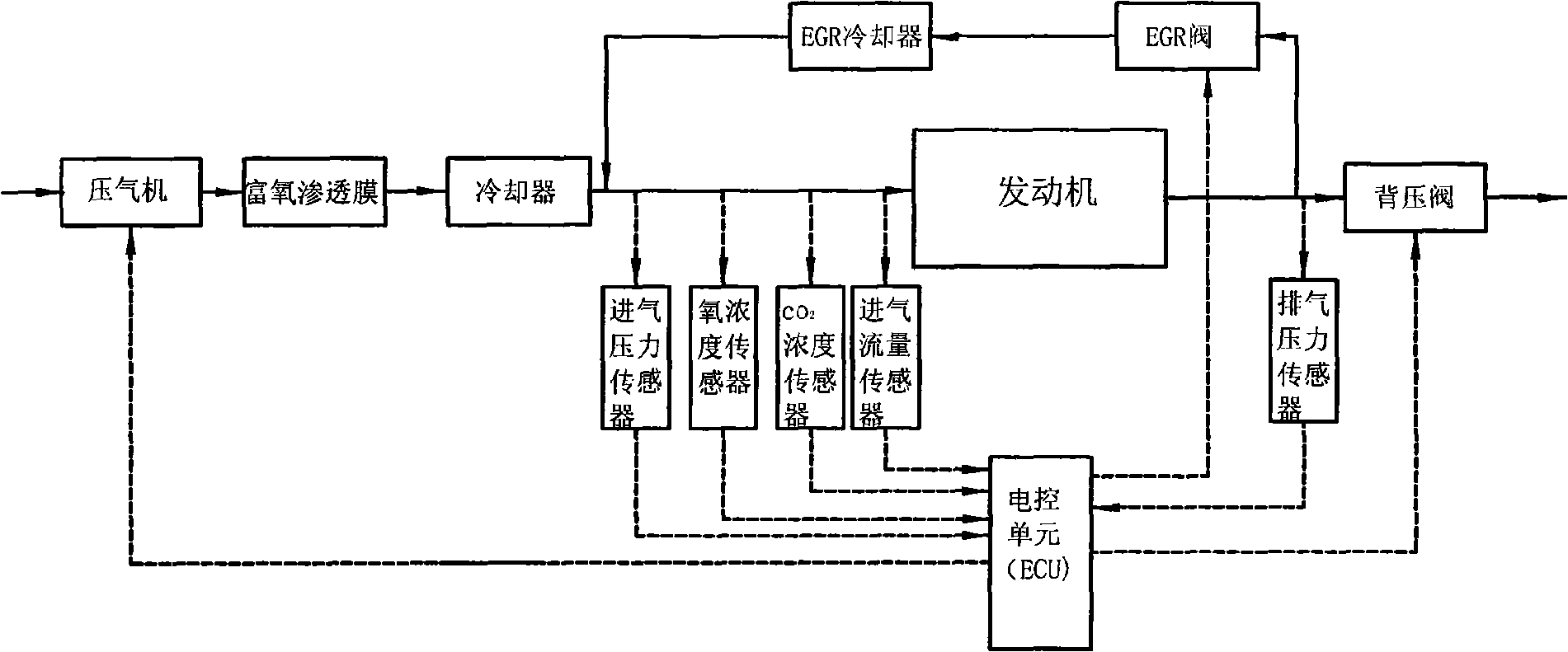

[0017] A pure oxygen combustion engine system for a vehicle, including an engine and an exhaust gas recirculation system, the exhaust gas recirculation system is mainly composed of a back pressure valve connected to the outlet of the exhaust manifold of an internal combustion engine, an EGR valve, and an EGR cooling valve connected to the outlet of the EGR valve. The outlet of the EGR cooler is connected to the intake manifold of the internal combustion engine. The innovation of this system is that the intake manifold of the engine is also connected with the output pipeline of a high-pressure oxygen storage tank. An oxygen concentration sensor is installed, and the signal output end of the oxygen concentration sensor is connected with an inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com