System and method for heating feed water through reheated steam to achieve deep peak regulation

A technology for reheating steam and water supply, which is applied in the steam generation method, control system, steam boiler and other directions using heat carrier, can solve the problems of poor ignition stability of pulverized coal, reduced hydrodynamic safety, and poor practicability. Improved ignition and stable combustion performance, improved ignition stability, and high energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

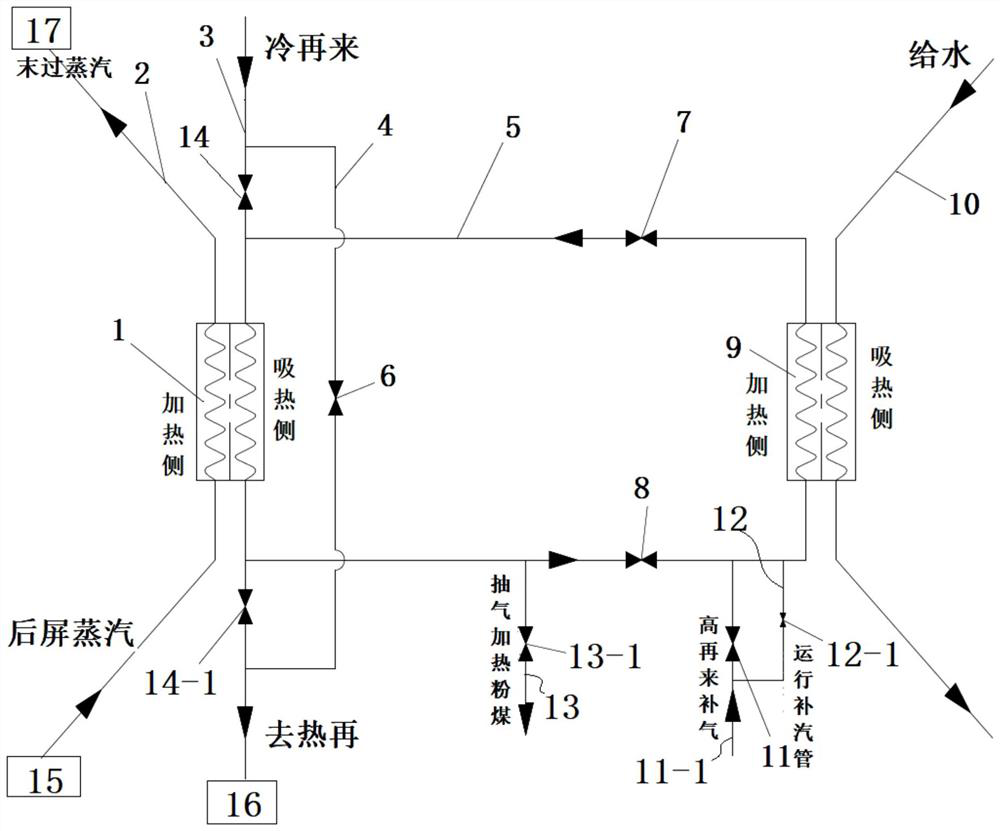

[0040] refer to figure 1 , the system for using reheated steam to heat feed water to achieve deep peak regulation in this embodiment includes a steam-steam heat exchanger 1, a superheated steam pipeline 2, a reheater cold section pipeline 3, a steam-steam heat exchanger bypass pipeline 4, a steam-water exchange Heater circulation pipe 5, steam-steam heat exchanger bypass valve 6, first circulation pipe valve 7, second circulation pipe valve 8, steam-water heat exchanger 9, water supply pipe 10, high resupply steam valve 11, high re-run Steam supply pipeline 12, supply steam control valve 12-1, primary air pulverized coal pipeline 13, extraction steam control valve 13-1, first cold-re-steam blocking valve 14, second cold-re-steam blocking valve 14-1; The heat exchanger 1 is used as a long-term operation equipment. The inlet of the heating side is connected with the outlet steam pipe of the screen superheater, the outlet of the heating side is connected with the superheated stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com